Heat treatment process for reducing sensitization degree of austenitic stainless steel

A technology of austenitic stainless steel and sensitization degree, applied in the field of heat treatment of stainless steel materials and austenitic stainless steel heat treatment process, can solve the problems of immature research, improve the resistance to intergranular corrosion, reduce the residence time, and improve the operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

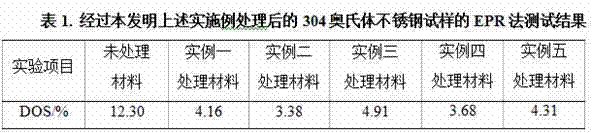

Examples

Embodiment 1

[0023] In this embodiment, a heat treatment process for reducing the sensitization degree of austenitic stainless steel, the steps are as follows:

[0024] a. Take a 304 austenitic stainless steel sample with a size of 80×10×4mm, and carry out segmental annealing treatment on the austenitic stainless steel sample under the protection of reducing atmosphere, and the reducing protective atmosphere adopts N 2 :H 2 The mixed gas whose molar ratio is 2:3, specifically adopts the four-stage annealing process, and the control conditions of the staged annealing process are as follows:

[0025] The first stage of annealing process: the annealing furnace is raised to 300°C at a rate of 5°C / min, and held for 0.5h;

[0026] The second stage of annealing process: the annealing furnace is raised to 1350°C at a heating rate of 10°C / min, and held for 0.5h;

[0027] The third stage annealing process: cooling to 1200°C with the furnace, holding for 12 hours;

[0028] The fourth stage anneal...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] In this embodiment, a heat treatment process for reducing the sensitization degree of austenitic stainless steel, the steps are as follows:

[0034] a. A 304 austenitic stainless steel sample with a size of 80×10×4mm was taken, and the austenitic stainless steel sample was annealed in stages under the protection of a reducing atmosphere. The reducing atmosphere was pure H 2 , specifically using a four-stage annealing process, the control conditions of the staged annealing process are as follows:

[0035] The first stage of annealing process: the annealing furnace is raised to 400°C at a rate of 10°C / min, and kept for 5 hours;

[0036] The second stage annealing process: the annealing furnace is raised to 1450°C at a heating rate of 30°C / min, and kept for 5 hours;

[0037] The third-stage annealing process: cooling to 1000°C with the furnace and holding for 24 hours;

[0038] The four...

Embodiment 3

[0042] This embodiment is basically the same as the previous embodiment, and the special features are:

[0043] In this embodiment, a heat treatment process for reducing the sensitization degree of austenitic stainless steel, the steps are as follows:

[0044] a. Take a 304 austenitic stainless steel sample with a size of 80×10×4mm, and carry out segmental annealing treatment on the austenitic stainless steel sample under the protection of reducing atmosphere, and the reducing protective atmosphere adopts N 2 :H 2 The mixed gas whose molar ratio is 3:7, specifically adopts the four-stage annealing process, and the control conditions of the staged annealing process are as follows:

[0045] The first stage of annealing process: the annealing furnace is raised to 350°C at a rate of 5°C / min, and kept for 2 hours;

[0046] The second stage annealing process: the annealing furnace is raised to 1450°C at a heating rate of 20°C / min, and kept for 2 hours;

[0047] The third stage ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com