Method for directly generating tool path based on measured data

A tool path and measurement data technology, applied in digital control, instrument, computer control, etc., can solve problems such as scattered, achieve the effect of improving versatility, avoiding cumbersome processes, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

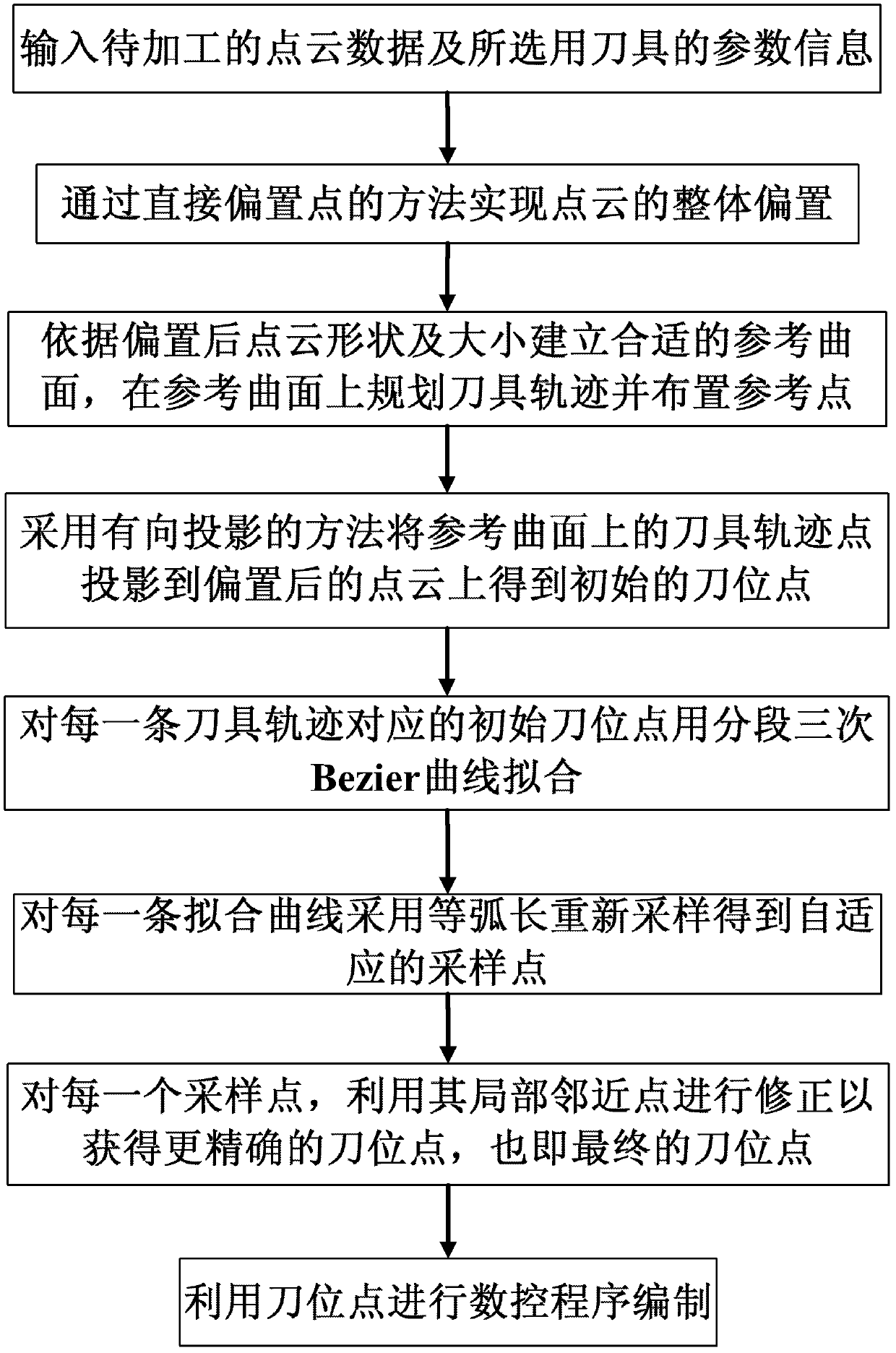

[0026] According to the method for directly generating the tool path of CNC machining based on measurement data in the present invention, the whole generation process is as follows: figure 1 As shown, it specifically includes the following steps:

[0027] (1) Use the method of direct offset point to offset the point cloud surface (that is, the measurement data, which is obtained by measuring the workpiece to be processed by non-contact measurement equipment such as laser interferometer);

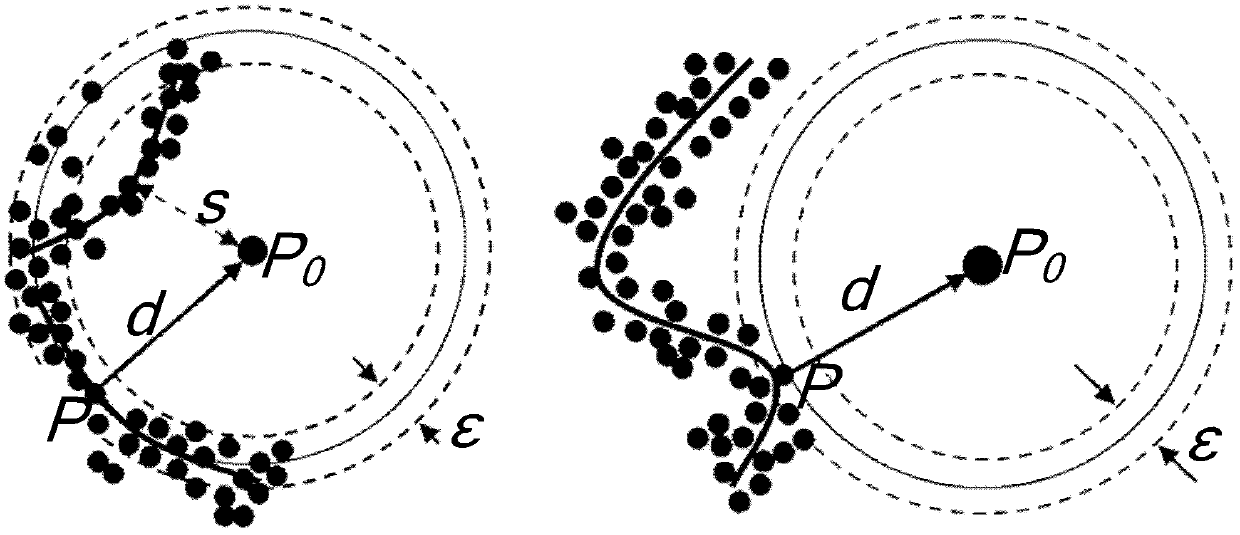

[0028] Figure 2c The results of point cloud biasing are shown, where the inner larger points represent the original point cloud and the outer smaller points represent the biased point cloud. Because it is necessary to determine the tool position point information during tool machining during NC programming, that is, the motion track of the tool center; and the tool has a certain volume, the tool position point usually deviates from the curved surface to be processed by a certain distance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com