Arc length control method for impulse arc welding

An arc length and pulse arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as instability of feedback control system, and achieve the effect of improving arc length controllability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

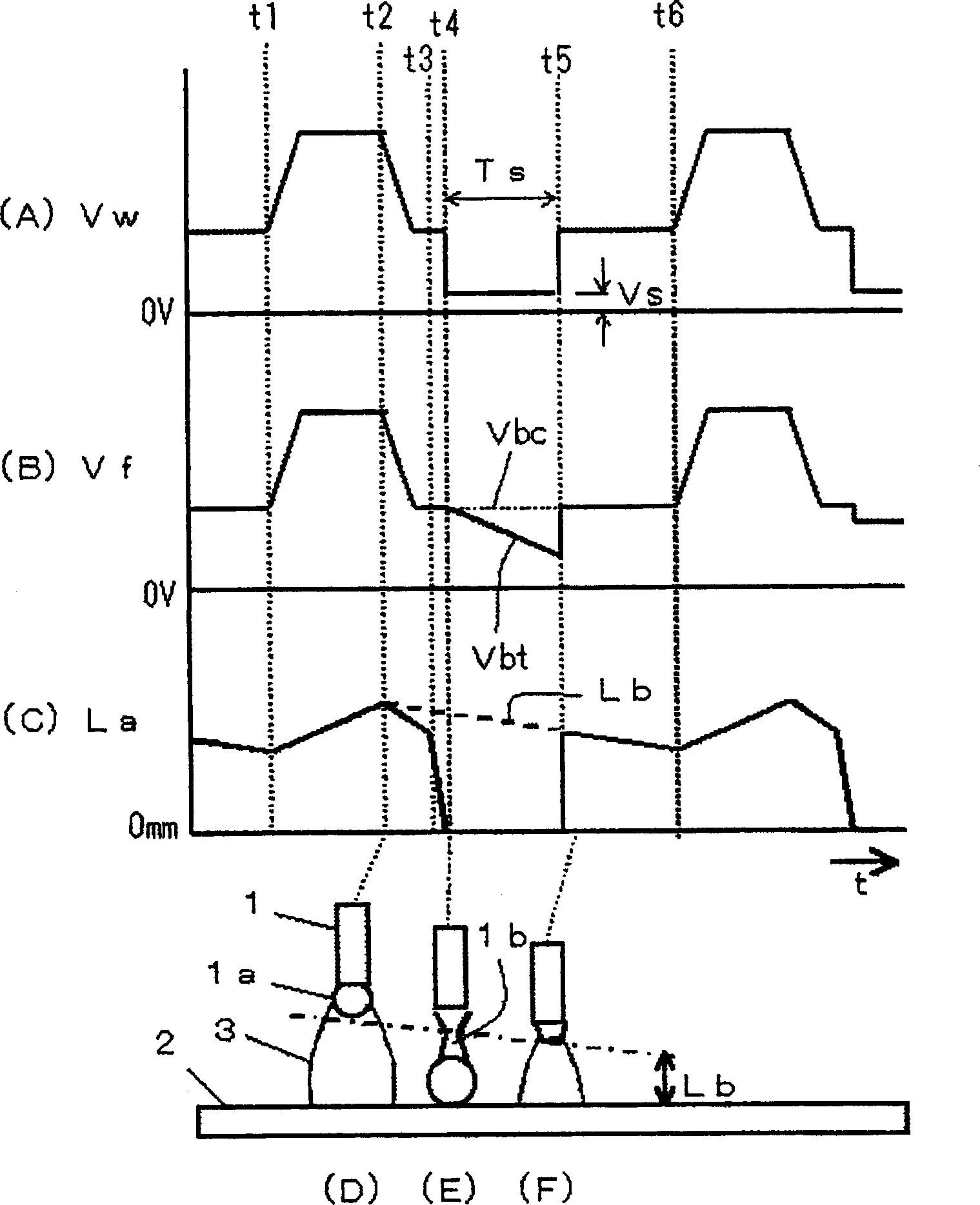

[0035] figure 1 It is a waveform diagram showing the arc length control method of the pulse arc welding according to the first embodiment of the present invention. figure 1 (A) shows the time change of the welding voltage Vw, figure 1 (B) represents the time change of the welding voltage limit value Vf, figure 1 (C) represents the time change of the arc length La, figure 1 (D) to (F) show the state of the arc generating part at each time point. figure 1 with the above Figure 6 Correspondingly, the average arc length is set to be short. exist figure 1 Among them, the operation during the period other than the short-circuit period Ts from time t4 to t5 is the same as the above-mentioned Figure 5 and Figure 6 The same, so the description is omitted. Next, the operation of Ts during the short circuit will be described.

[0036] In Example 1, such as figure 1 As shown in (B), the base voltage lower limit value Vbt gradually decreases with the passage of time in...

Embodiment 2

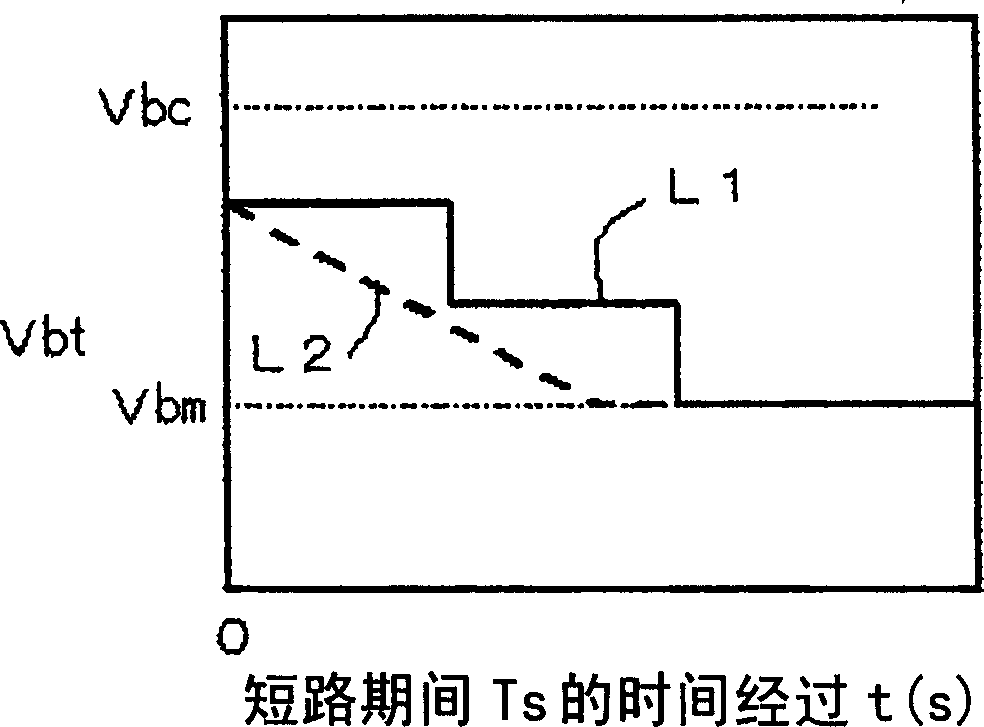

[0042] image 3 It is a graph showing the change pattern of the base voltage lower limit value Vbt with the passage of time during the short-circuit period. image 3 The horizontal axis of represents the elapsed time from the start of the short-circuit period, and the vertical axis represents the value of the base voltage lower limit value Vbt. Such as image 3 As shown, the characteristic L1 drops in steps from the base voltage reference value Vbc. At this time, every few milliseconds, several V drops. In addition, the characteristic L2 falls in a ramp shape, and the maximum lower limit value Vbm is set, and will not fall below this value. The maximum lower limit value Vbm is about 4 to 15V, and an appropriate value is selected according to welding conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com