Valveless piezoelectric micro pump

A micro-pump, piezoelectric technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machinery, etc., can solve the difficulty of V-shaped pipe manufacturing and installation, small area ratio of inlet and outlet pipes, and small flow adjustment range. and other problems, to achieve the effect of light weight, large flow adjustment range and no electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

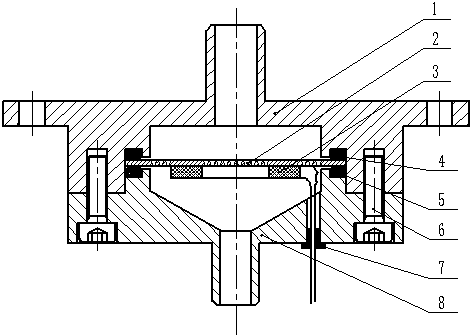

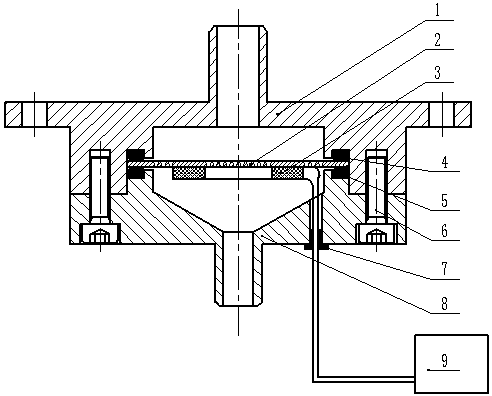

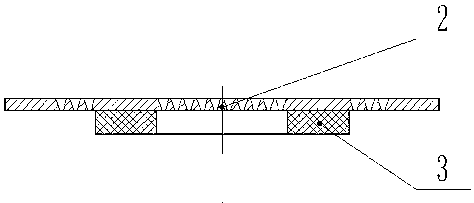

[0022] combine figure 1 As shown, a valveless piezoelectric micropump includes a vibrating plate, a pump body 8 and an upper cover plate 1 connected to the pump body 8 by bolts 6, and a cavity is formed between the upper cover plate 1 and the pump body 8 , the vibrating plate is set between the upper cover plate 1 and the pump body 8, the cavity is divided into a liquid negative pressure chamber and a liquid outlet pressure chamber by the vibrating plate, and the vibrating plate is composed of a vibrating diaphragm 2 and an annular piezoelectric ceramic sheet 3 coaxial In the bonding structure, the piezoelectric ceramic sheet 3 is made of PZT-8, with an outer diameter of 16mm, an inner diameter of 8mm, and a thickness of 0.6mm. The vibrating diaphragm 2 is made of 316L stainless steel, with a thickness of 0.1mm and a diameter of 25mm. The two electrodes of the piezoelectric ceramic sheet 3 are connected with power lines, the pump body 8 is provided with a power line hole for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com