Reaction cavity lining and reaction cavity including the same

A reaction chamber and lining technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of inconsistent gas flow, uneven internal pressure, uneven distribution of plasma, etc., to achieve uniform gas distribution, Effect of Uniform Etch Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

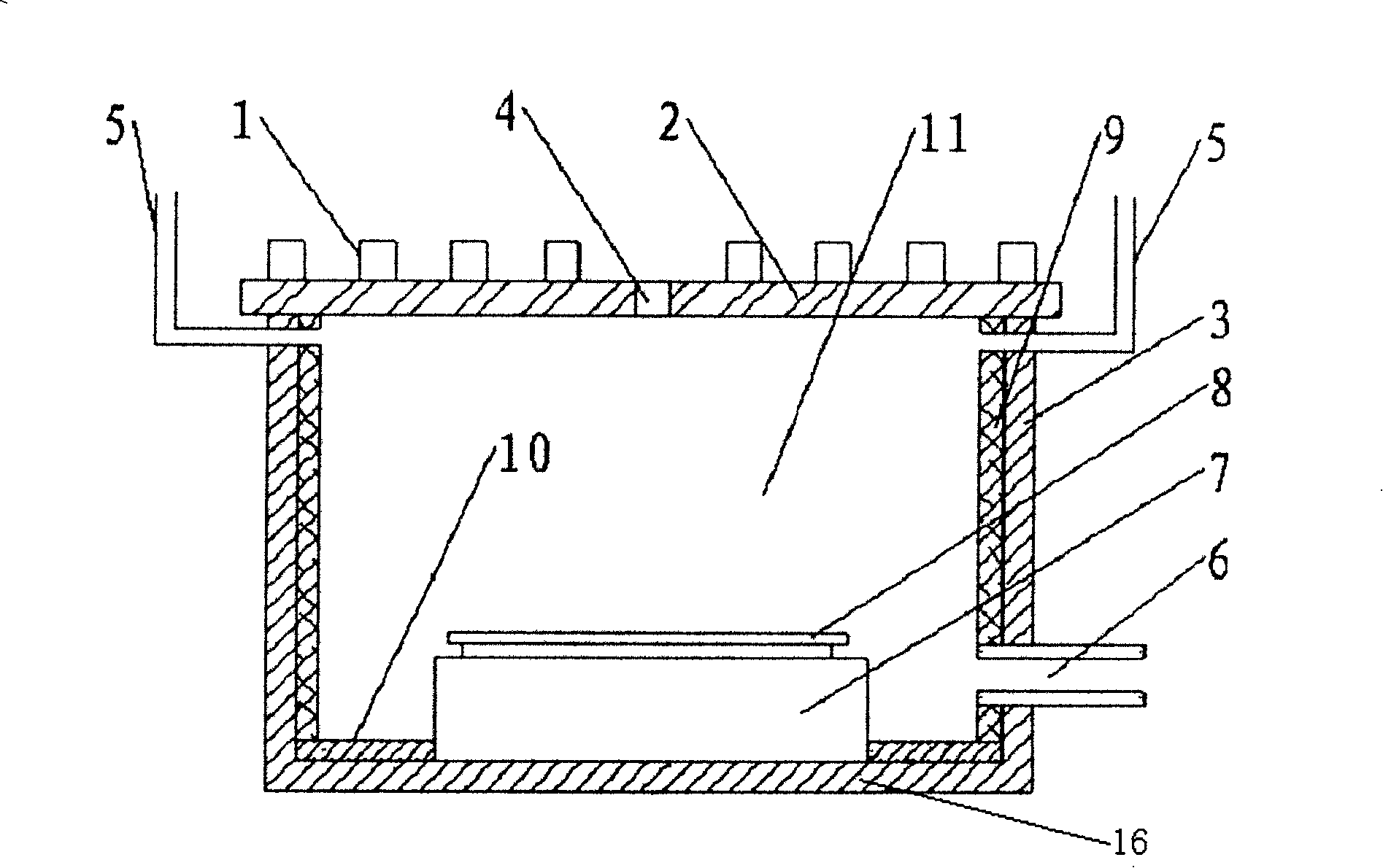

[0028] The reaction chamber lining of the present invention is mainly used to protect the wall of the reaction chamber. The reaction chamber mentioned here mainly refers to the reaction chamber of the semiconductor wafer processing equipment, and may also be other chambers.

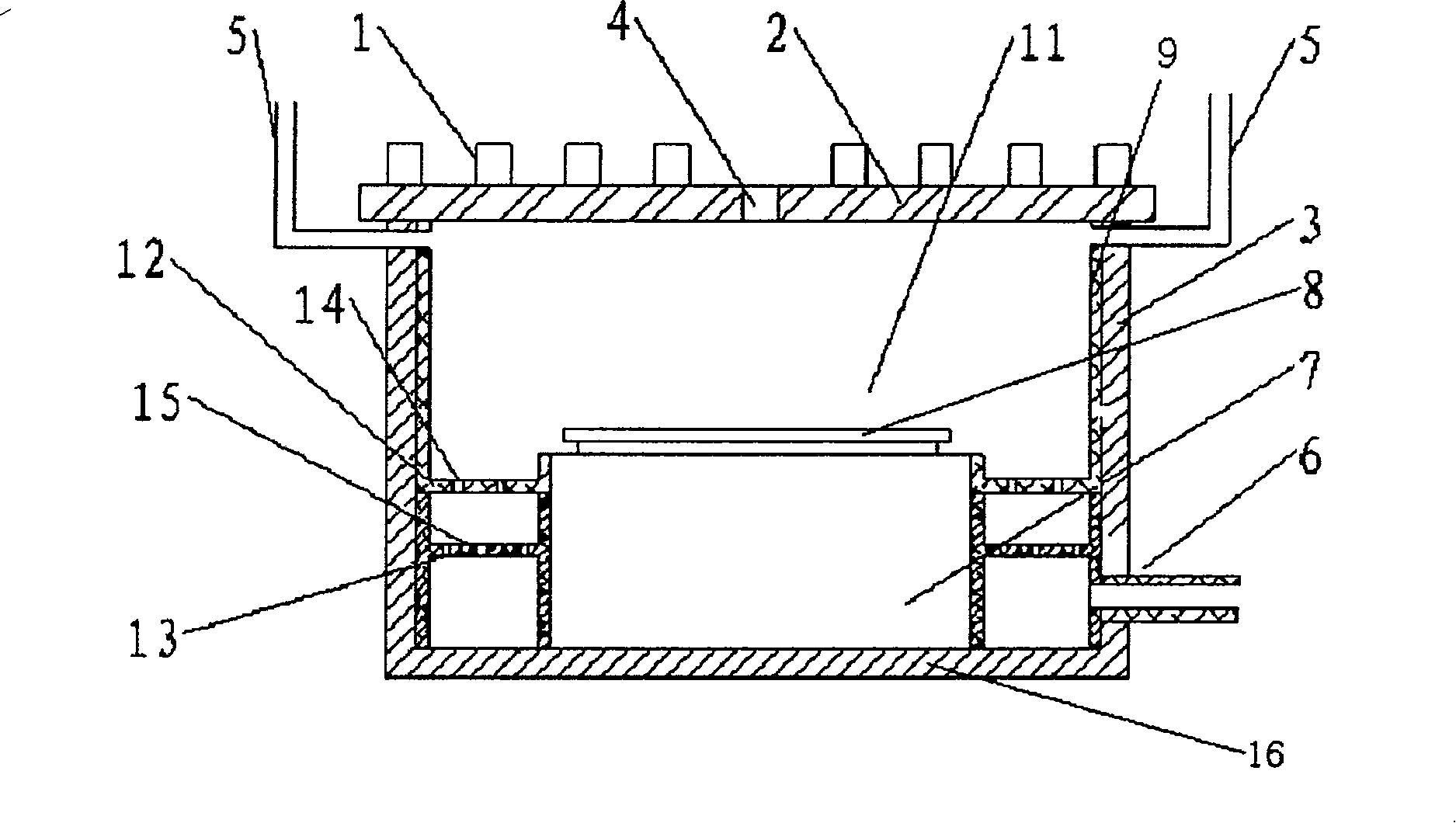

[0029] Its preferred specific implementation is as figure 2 As shown, it includes a side lining 9 and a bottom lining, the bottom lining is higher than the lower edge of the side lining 9, and the bottom lining has two layers, including an upper lining 12 and a lower lining 13, and the upper inner lining The lining 12 has a plurality of upper layer lining holes 14; the lower layer lining 13 has a plurality of lower layer lining holes 15. The upper layer lining holes 14 and the lower layer lining holes 15 are preferably arranged alternately.

[0030] The bottom lining can also have multiple layers, but there is at least one layer. There are multiple lining holes on the bottom lining, so that the space ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com