125-degree irradiation-crosslinked elastomer cable material used for new energy automobile high-voltage cable and manufacture method of elastomer cable material

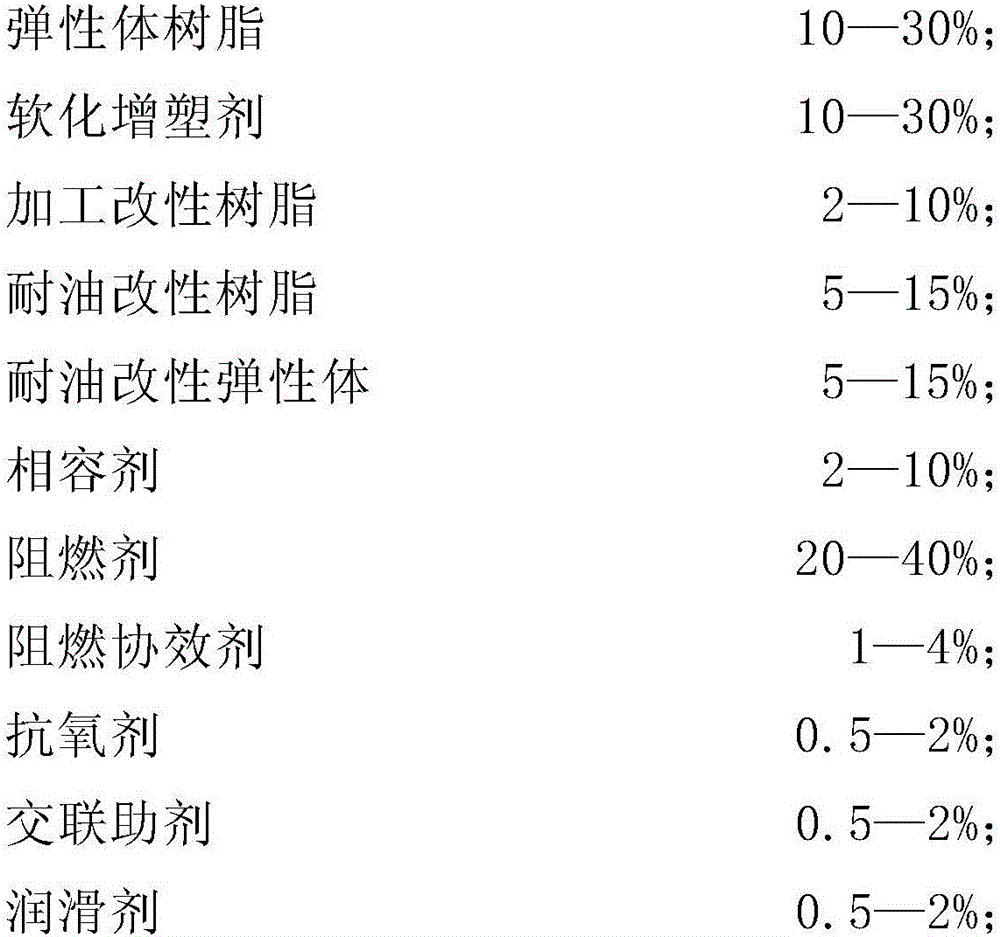

A technology that combines new energy and elastomers. It is used in plastic/resin/wax insulators, organic insulators, etc. to achieve the effects of good flame retardancy, excellent performance and excellent processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a preparation method of the above-mentioned 125-degree irradiation cross-linked elastomeric cable material for high-voltage wires of new energy vehicles. The preparation method includes the following steps:

[0061] (a) Weigh the elastomer resin and the oil-resistant modified elastomer in the proportion of the formula, place it in a high-speed mixer, add a softening plasticizer, mix for 3-5 minutes, and place it for at least 12 hours for later use;

[0062] (b) Add the processed modified resin, oil-resistant modified resin, compatibilizer, flame retardant, flame retardant synergist, antioxidant, cross-linking auxiliary agent and lubricant in the formulated amount, and mix for 5 to 10 minutes;

[0063] (c) Pour the mixed material into a twin-screw extruder for extrusion and granulation. The temperature of each section of the fuselage of the twin-roller kneader is as follows: 150°C-160°C, 160°C-170°C, 170°C ℃~180℃, 180℃~190℃, 190℃~195℃,...

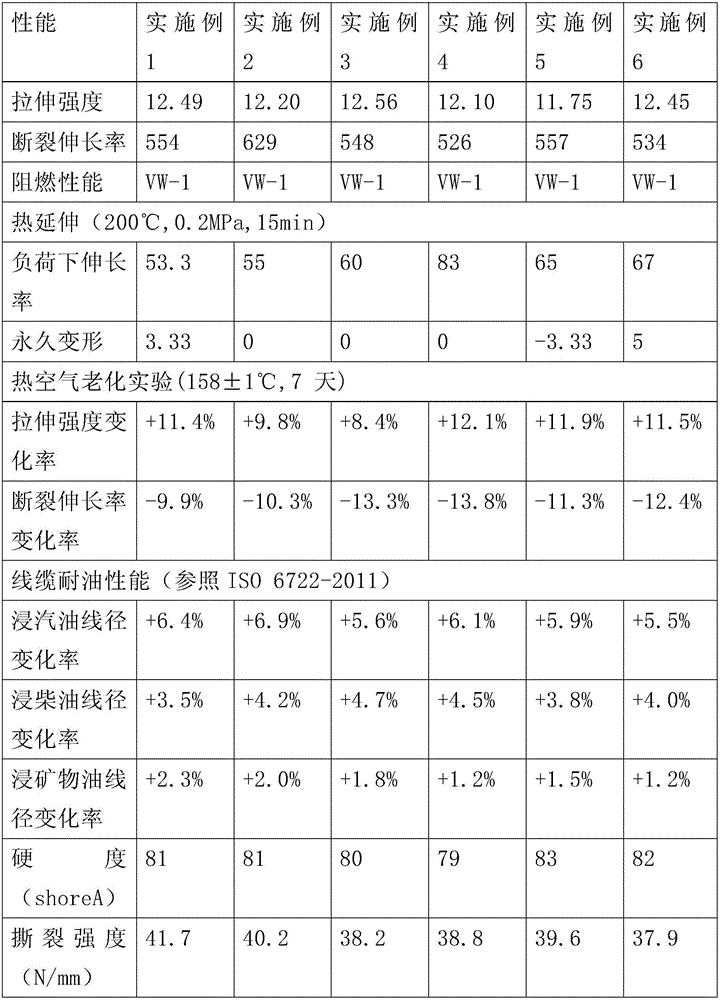

Embodiment 1

[0075] The name of each component and the parts by weight of each component of the 125-degree irradiation cross-linked elastomeric cable material formula for high-voltage wires of new energy vehicles in Example 1 are shown in Table 1:

[0076] Table 1

[0077] name weight / kg name weight / kg SEBS 30 Organic hypophosphite 15 EPDM 30 Clay 10 PP 10 1010 0.6 HDPE 15 DLTP 0.8 TPEE 10 168 1 Maleic anhydride grafted EPDM rubber 5 TAIC 1 32# paraffin oil 50 PE wax 1 Melamine cyanurate 40 Silicone masterbatch 1.5 Resorcinol bis(diphenyl phosphate) (RDP) 10

[0078] The preparation method of the 125-degree irradiation cross-linked elastomeric cable material for high-voltage wires of new energy vehicles of this embodiment is as follows:

[0079] Weigh SEBS, EPDM, and TPEE according to the ratio in Table 1, place them in a high-speed mixer, add 32# paraffin oil, mix for 3-5 minutes, and place t...

Embodiment 2

[0085] The names and parts by weight of the components of the 125-degree irradiation crosslinked elastomeric cable material formula for high-voltage wires of new energy vehicles in Example 2 are shown in Table 2:

[0086] Table 2

[0087] name weight / kg name weight / kg SEBS 30 Organic hypophosphite 12 EPDM 30 Clay 8 PP 10 1010 0.6 Polyphenylene Oxide (PPO) 15 DLTP 0.8 Nitrile rubber 10 168 1 Maleic anhydride grafted EPDM rubber 5 TAIC 1 32# paraffin oil 50 PE wax 1 Melamine cyanurate 35 Silicone masterbatch 1.5 Resorcinol bis(diphenyl phosphate) (RDP) 10

[0088] The preparation method of the 125-degree irradiation cross-linked elastomeric cable material for high-voltage wires of new energy vehicles of this embodiment is as follows:

[0089] Weigh the SEBS, EPDM rubber, and nitrile rubber in the ratio shown in Table 2, place them in a high-speed mixer, add 32# paraffin oil, mix for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com