Quick forming screw extruding jet device for thermoplastic particle material

A technology of screw extrusion and granulation, which is applied in the field of rapid prototyping extrusion nozzle device, which can solve problems such as the insurmountable delay of nozzle wire discharge and salivation, the increase of the weight of the nozzle and the complexity of coupling control, and the inability to reduce the cost of prototyping, etc. , to achieve the effect of clear local details, good start and stop effect of silk output, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

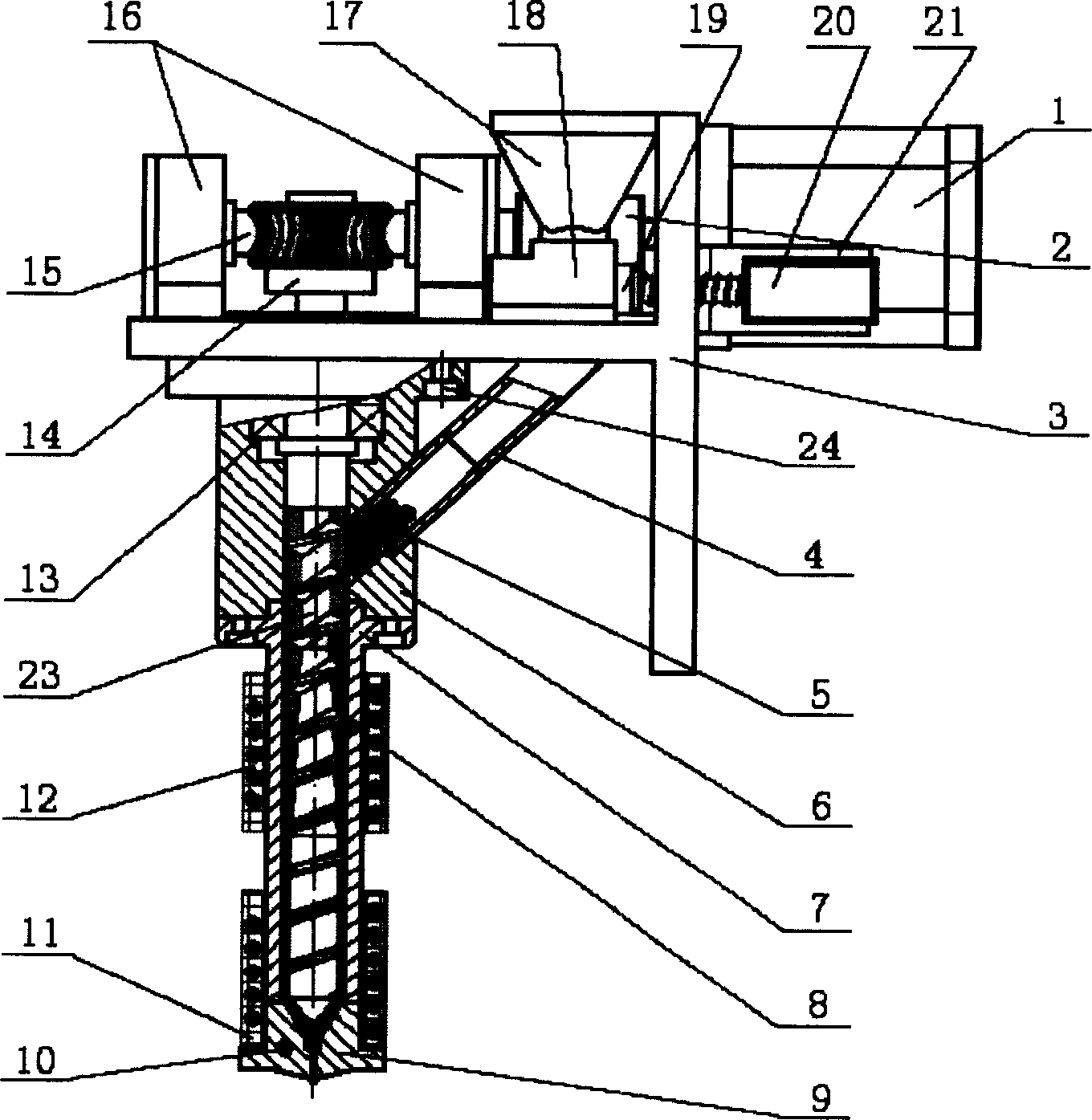

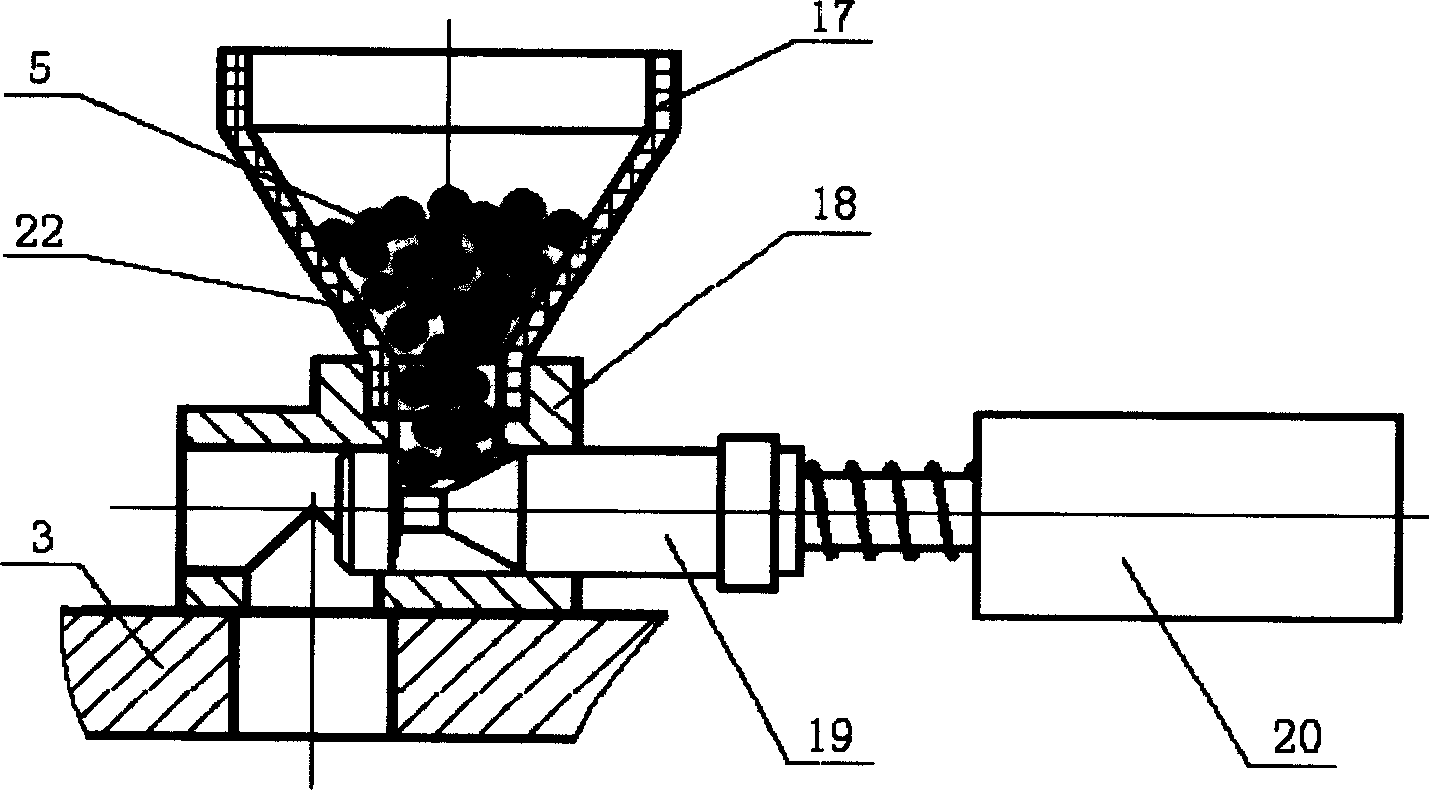

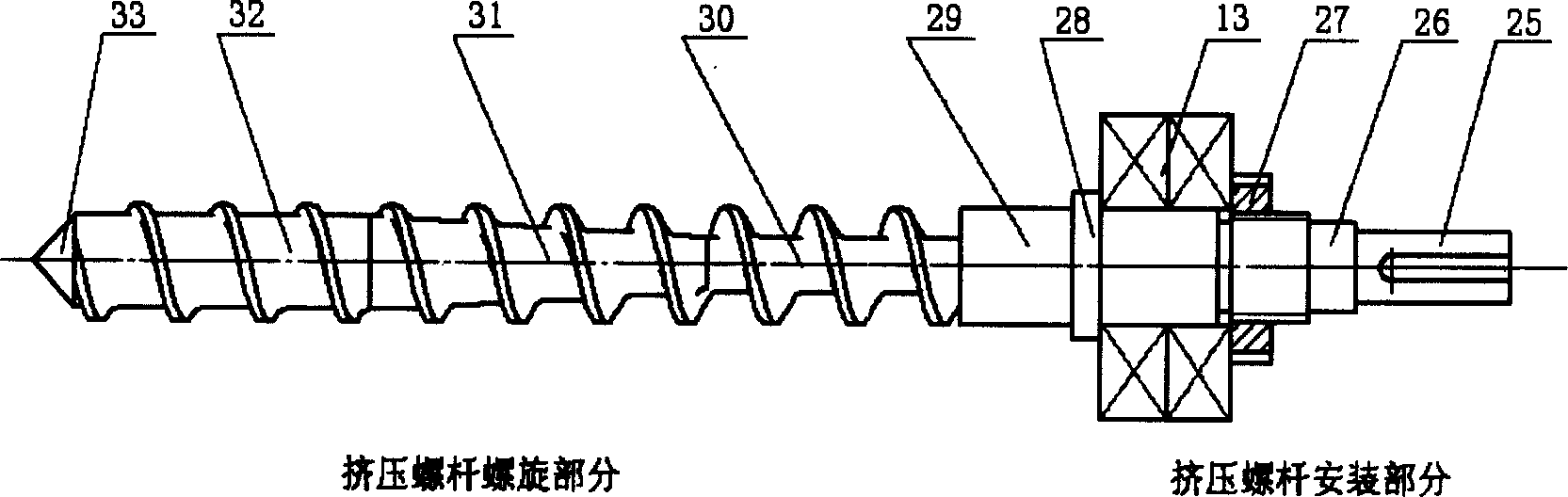

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the present invention includes a control motor 1, a shaft coupling 2, a connecting plate 3, a connecting barrel 4, an upper barrel 6, a lower barrel 7, an extrusion section temperature sensor 8, a nozzle 9, a metering section temperature sensor 10, Lower heating ring 11, upper heating ring 12, worm wheel 14, worm 15, worm support 16, hopper 17, adapter 18, push rod 19, electromagnet 20, connecting bracket 21, material level detection sensor 22, extrusion screw 23 . Among them, the connecting barrel 4, the hopper 17, the conversion joint 18, the push rod 19, the electromagnet 20, the connecting bracket 21 and the material level detection sensor 22 form the push rod feeding mechanism; the coupling 2, the worm wheel 14, the worm 15 and the worm support Seat 16 forms the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com