Long-stroke high-frequency-response quick cutter servo device

A servo device and high-response technology, which is applied in the field of ultra-precision machining machinery and equipment, can solve the problems of insufficient travel of fast-tool servo devices, low machining efficiency of flying-tool milling, and low frequency response of slow-tool servo, achieving compact size and simple processing , Improve the effect of dynamic performance

Inactive Publication Date: 2012-07-11

NAT UNIV OF DEFENSE TECH

View PDF5 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Existing ultra-precision machining methods based on advanced numerical control technology, especially single-point diamond cutting technology, have been widely used in non-rotational symmetric surface processing, but currently for non-rotational symmetric optical surfaces with a height difference of several millimeters, the existing The stroke of the fast tool servo device is not enough, the frequency response of the slow tool servo is low, the processing cycle is long, the accuracy is affected by the environment, and the milling efficiency of the flying knife is low and it is not suitable for the processing of certain surface shapes. Therefore, it is necessary to study a large stroke , High-response, high-precision tool servo system to solve the processing of this type of non-rotational symmetrical surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0052] The rest of the structure of Embodiment 2 is basically the same as that of Embodiment 1, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

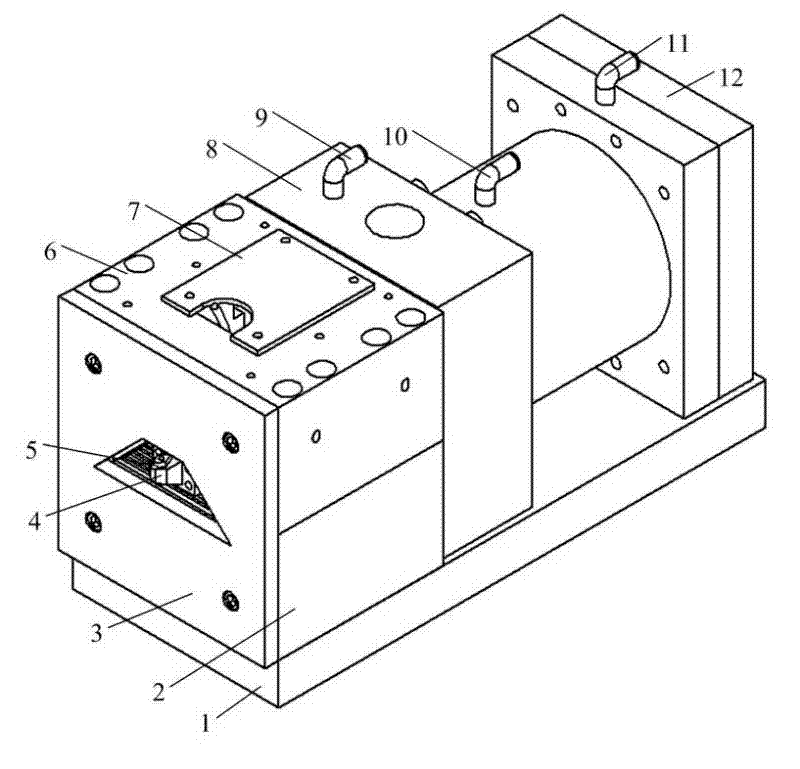

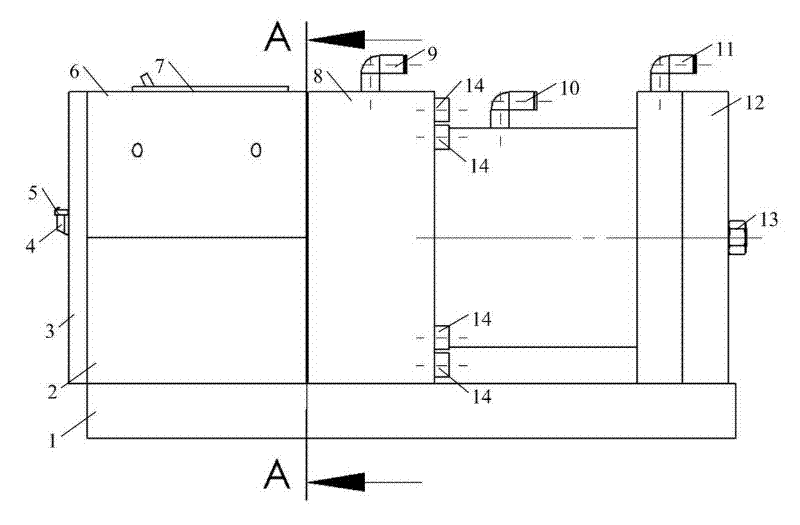

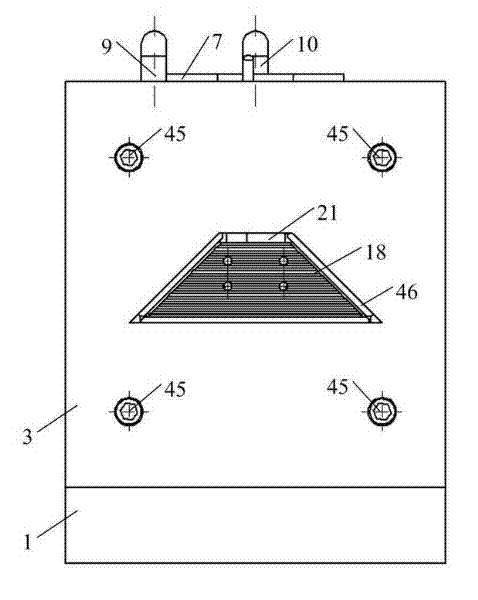

The invention discloses a long-stroke high-frequency-response quick cutter servo device, which comprises a driving component and a cutter saddle moving component. The driving component is mounted on a mounting component, the cutter saddle moving component is connected with the driving component and consists of a floatation guide track supported by a floatation support component, one end of the floatation guide track is connected with the driving component, and the other end of the floatation guide track is connected with a cutter saddle provided with a cutter. The long-stroke high-frequency-response quick cutter servo device has the advantages of high processing precision, long stroke, high speed of the cutter, high acceleration and the like.

Description

technical field [0001] The invention mainly relates to the field of ultra-precision processing mechanical equipment, in particular to a fast tool servo device. Background technique [0002] Ultra-precision machining is a processing method that has reached or has reached the highest dimensional accuracy in a certain period. At present, the precision of ultra-precision machining has ranged from micron to sub-micron or even nanometer level. It is widely used in optical systems, electronic information, automobiles, household appliances and weaponry, etc. field. Ultra-precision machining equipment must have extremely high motion accuracy. The straightness of the guide rail must reach the sub-micron level within the full stroke range (hundreds of millimeters), the rotation accuracy of the spindle should reach tens of nanometers, and the resolution of linear motion should be below the nanometer level. With the development of modern optical technology, non-rotational symmetric surf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23Q1/25B23Q5/34

Inventor 尹自强李圣怡戴一帆田富竟刘晓冬

Owner NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com