Piezoelectric ultrasonic salt-bath heating nitriding device

A salt bath heating and ultrasonic technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of large energy consumption and long time of nitriding device, and achieve good economy and small energy loss. , Improve the effect of nitriding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

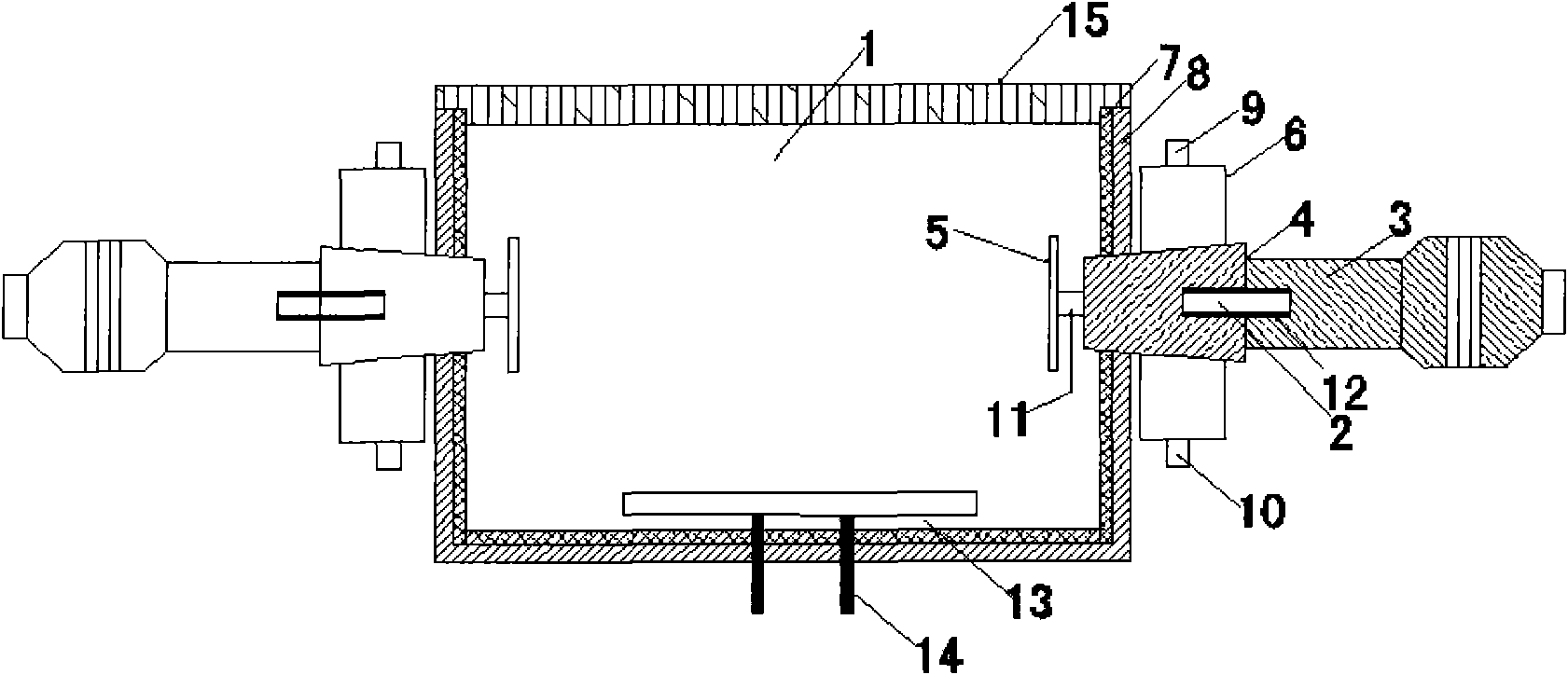

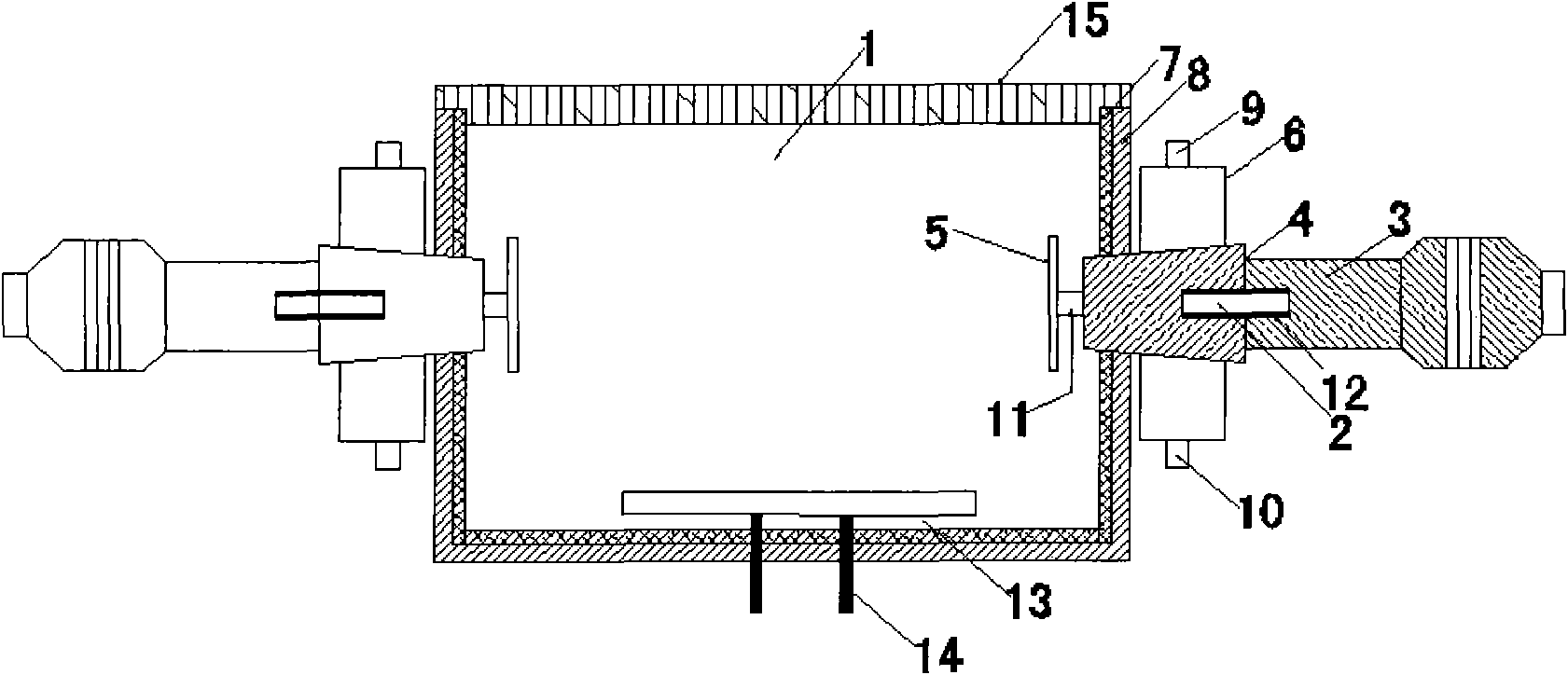

[0019] As shown in Fig. 1, the structure schematic diagram of piezoelectric ultrasonic salt bath heating nitriding device. The piezoelectric ultrasonic salt bath heating and nitriding device comprises a shell 8 with an insulating layer, a salt bath (groove) 1 in the shell, a heating plate 13, a wiring support column 14, a top cover 15 and a piezoelectric ultrasonic device. The heating plate 13 is at the bottom of the bath 1, links to each other 14 with the wiring support column, and keeps a certain distance with the bottom of the salt bath 1 to prevent heat loss during heating; the wiring support column 14 leads to the outside of the salt bath 1 and can be connected with the power supply. The upper part of the salt bath 1 is provided with a top cover 15 to prevent volatilization of bath salt and loss of heat. Two sets of piezoelectric ultrasonic devices are mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com