Self-excited oscillation cavitation impinging stream reactor

A technology of impinging flow reactor and cavitator, which is applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, special compound water treatment, etc., can solve the problem of small cavitation area, large energy consumption of ultrasonic cavitation, and application The scope of the water is small and other problems, to achieve the effects of high cavitation intensity, enhanced sewage treatment efficiency, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing:

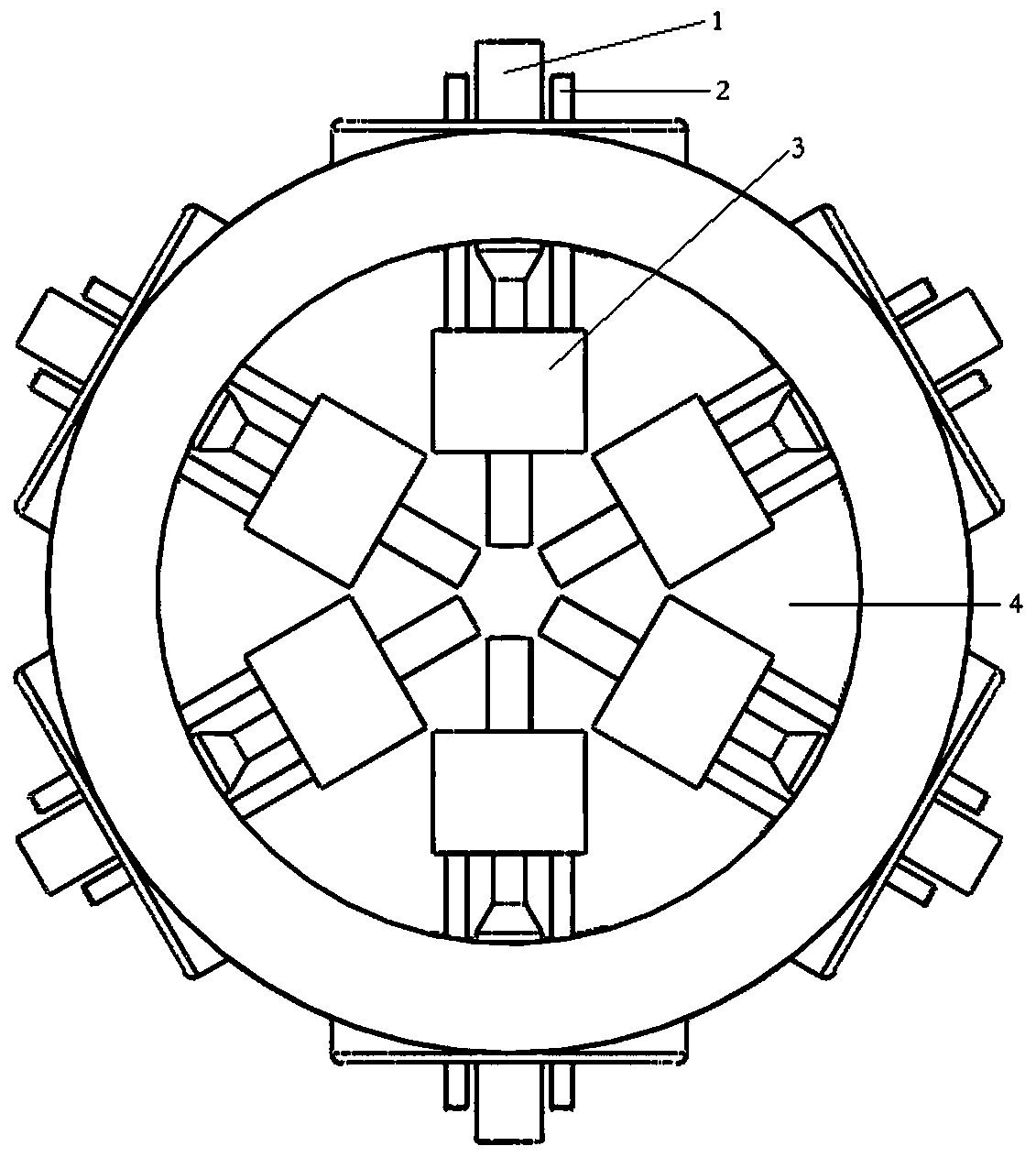

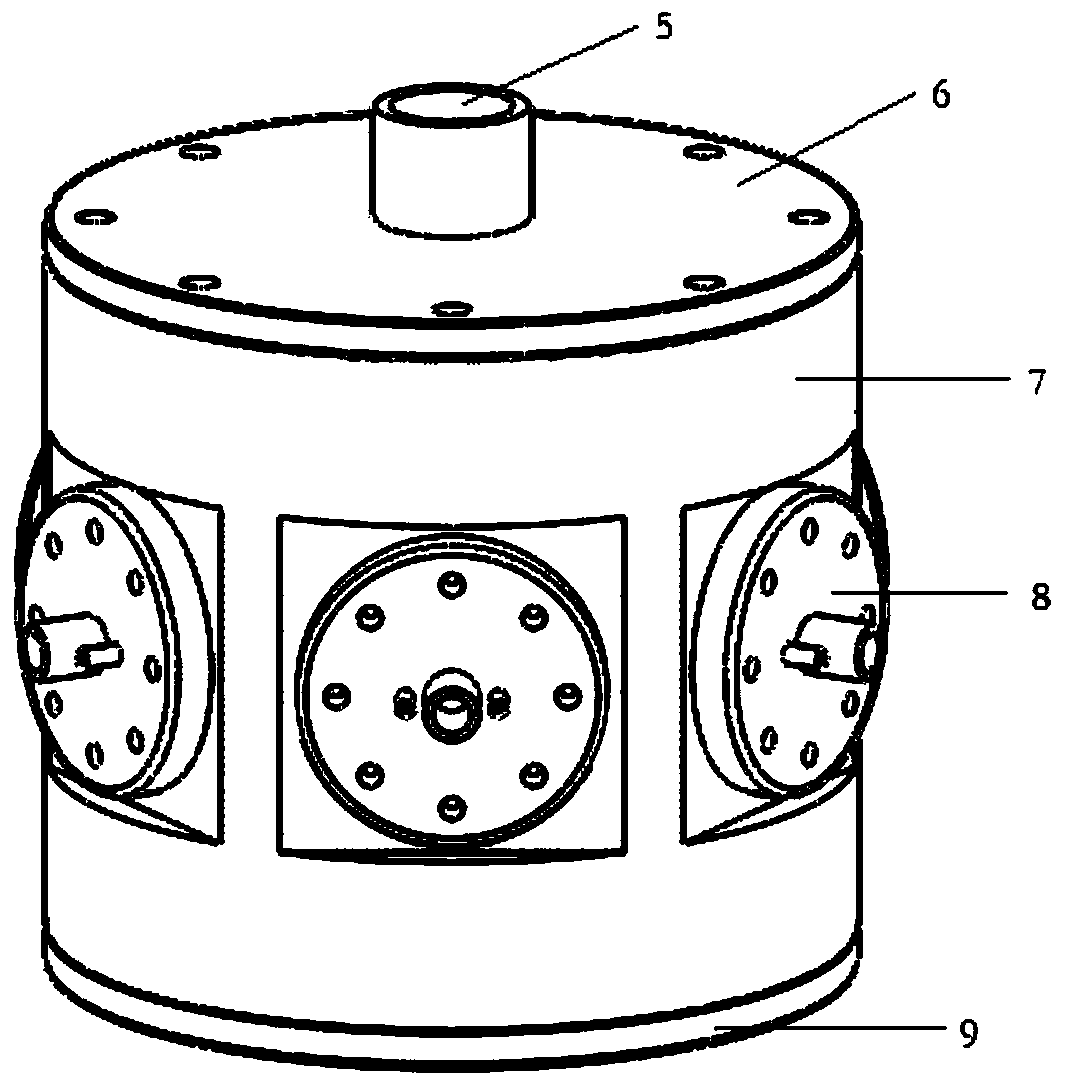

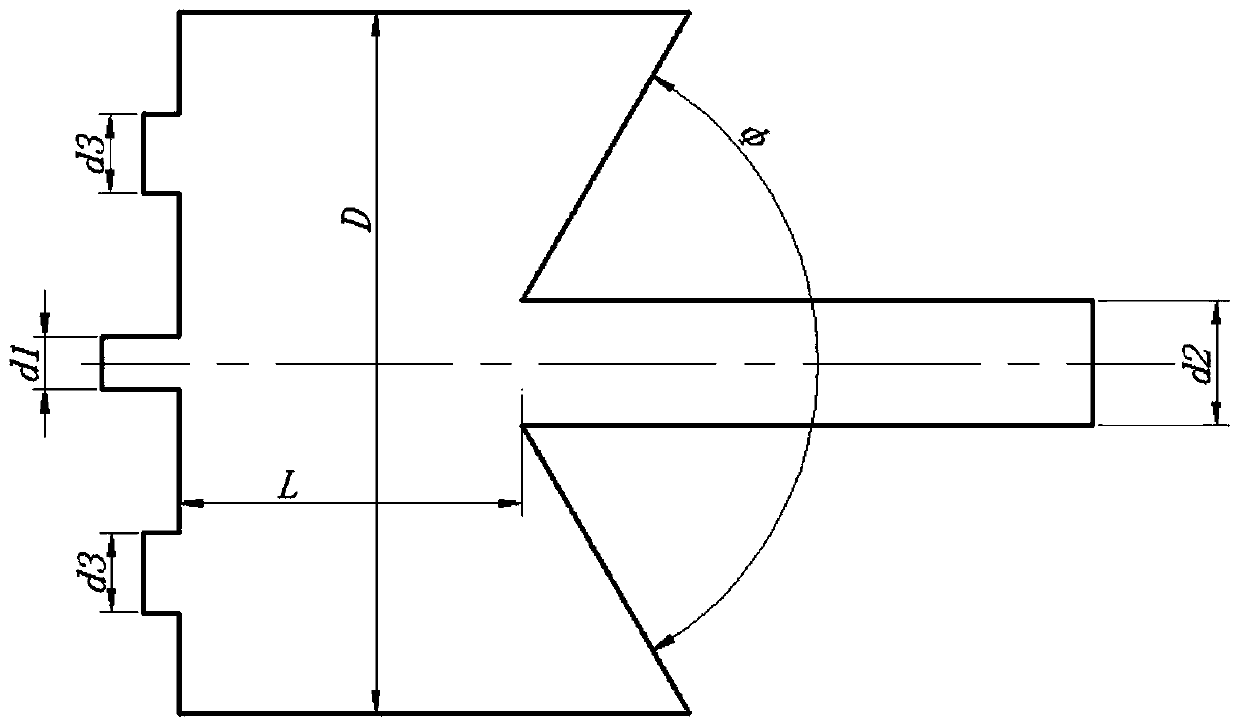

[0022] The invention provides a self-excited oscillation cavitation impingement flow reactor. figure 1 It is a schematic diagram of the internal structure of a self-excited oscillating cavitation impinging flow reactor of the present invention. figure 2 It is a front view of a self-excited oscillating cavitation impinging flow reactor of the present invention. Such as figure 1 figure 2 As shown, the present invention includes a liquid inlet pipe 1, an air inlet pipe 2, a cavitator 3, an impact chamber 4, a liquid outlet pipe 5, an upper cover plate 6, a wall plate 7, a flange plate 8, and a lower cover plate 9.

[0023] Such as figure 1 figure 2 As shown, the self-excited oscillating cavitation impingement flow reactor liquid inlet pipes can be six or other even numbers, evenly distributed on the periphery of the impact cavity, wherein the impact cavity ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com