Technique for extracting polysaccharide in glossy ganoderma mycelium cell and method thereof

A technology of Ganoderma lucidum mycelium and intracellular polysaccharide, which is applied in the directions of antitoxin, metabolic disease, antitumor drug, etc., can solve the problems of increasing production cost, difficulty in product separation, etc., so as to improve the yield, improve the separation efficiency, and shorten the extraction time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

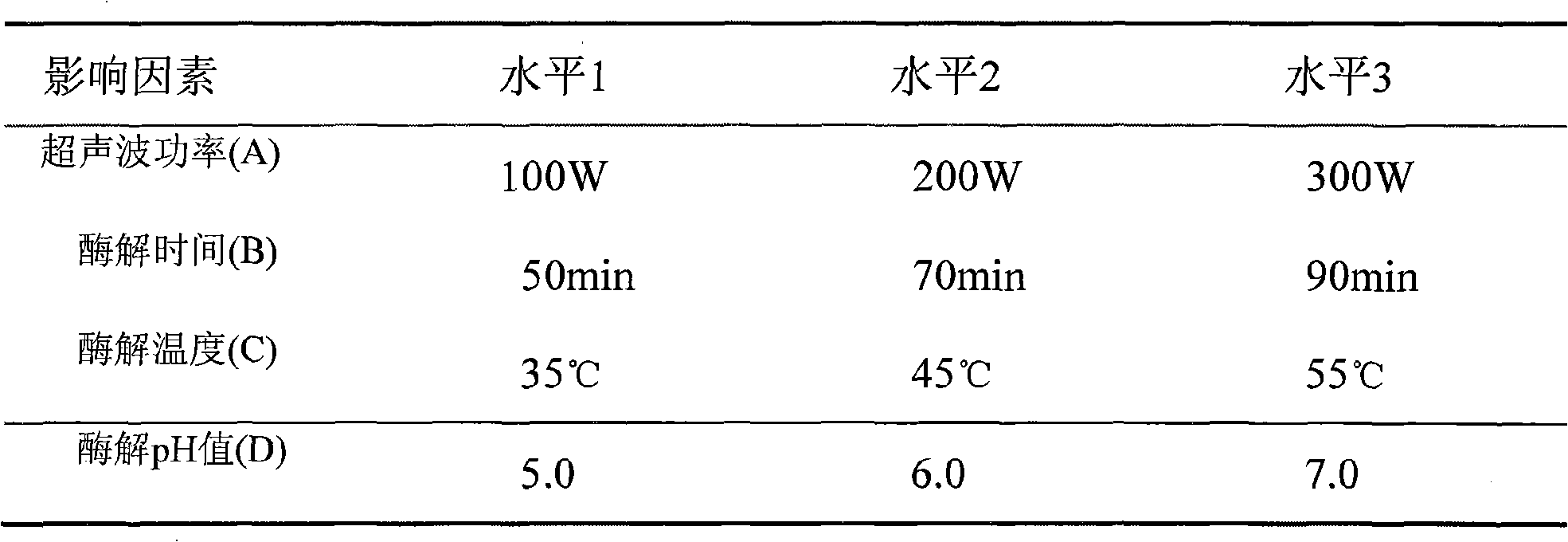

[0022] Ganoderma lucidum Chizhi No. 22 bacterial strain (provided by Zhejiang Academy of Forestry Sciences) mycelium submerged fermentation mycelium dry powder polysaccharide extraction process combination, its composition is that the ratio of material to liquid is 1: 30 by mass ratio, and the addition of compound enzyme is 2%, the ultrasonic power is 200W, the enzymolysis time is 50min, the enzymolysis temperature is 55°C, and the enzymolysis pH value is 5.0.

[0023] The method for determining the intracellular polysaccharide extraction process of the ganoderma lucidum mycelia is:

[0024] 1) The mycelium dry powder obtained from the submerged fermentation of the mycelium of Ganoderma lucidum Chizhi No. 22 strain (provided by Zhejiang Academy of Forestry Sciences) was selected.

[0025] 2) Determine the ratio of material to liquid

[0026] Polysaccharides were extracted by hot water extraction. Select 100g of mycelium dry powder from step 1), take the water addition multip...

Embodiment 2

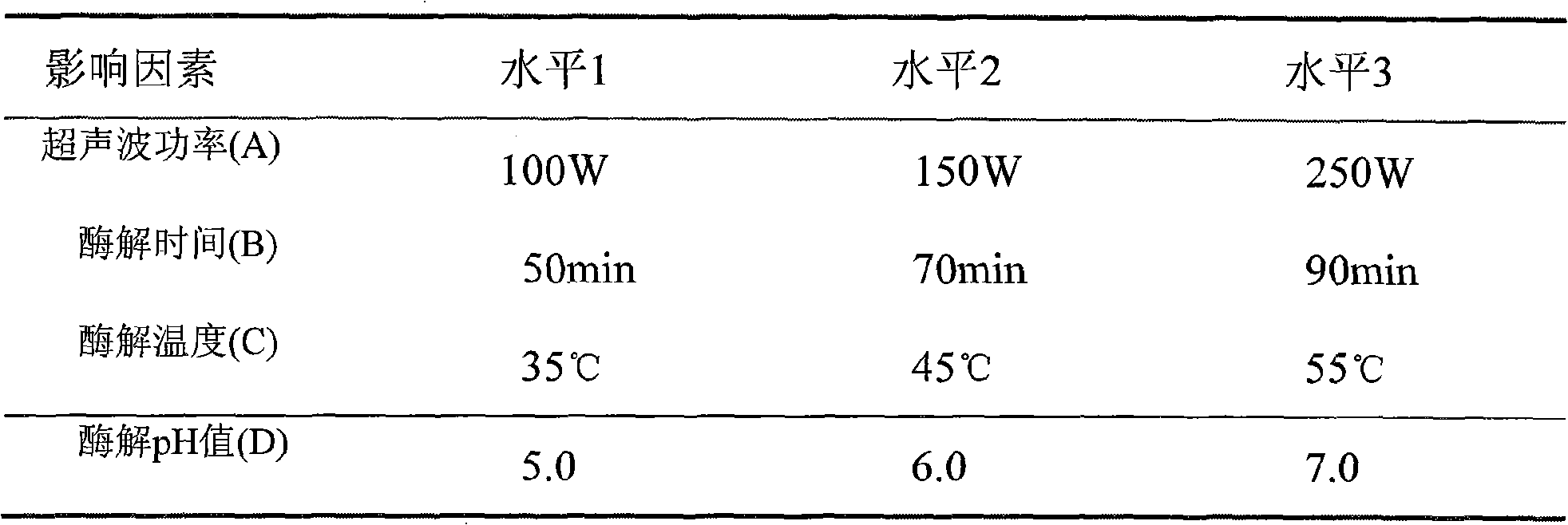

[0035] Ganoderma lucidum Chizhi No. 38 strain (provided by Zhejiang Academy of Forestry Sciences) mycelia dry powder polysaccharide extraction process combination obtained from mycelium submerged fermentation, its composition is that the ratio of solid to liquid is 1:40 by mass, and the amount of enzyme added is 3.0% Under the conditions, the ultrasonic power is 150W, the enzymolysis time is 40min, the enzymolysis temperature is 45°C, and the enzymolysis pH value is 7.0.

[0036] The method for determining the intracellular polysaccharide extraction process of the ganoderma lucidum mycelia is:

[0037] 1) Mycelium dry powder obtained from mycelium submerged fermentation of Ganoderma lucidum Chizhi No. 38 strain (provided by Zhejiang Academy of Forestry Sciences)

[0038] 2) Determine the ratio of material to liquid

[0039] Polysaccharides were extracted by hot water extraction. Select 100g of mycelium dry powder from step 1), take the water addition multiple as the analysis f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com