Method for separating and purifying plant sterols from seabuckthorn seeds

A technology for separation and purification of phytosterols, which is applied in the field of extraction of phytosterols, can solve the problems of high equipment cost, high vegetable oil dryness, and low production cost, and achieve the effects of shortened extraction time, simple operation method, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

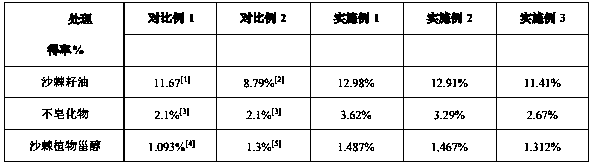

Embodiment 1

[0032] The selected sea buckthorn seeds are washed and aired. After crushing the sea buckthorn seeds, they are passed through a 60-mesh sieve, and dried in a constant temperature drying oven at 80°C for 5 hours to constant weight; the dried 100 g sea buckthorn seed powder is mixed with 800 mL n-hexane and soaked 120min, leaching with the aid of ultrasound at 60℃ for 40min, the extract is obtained by suction filtration, the filter residue is repeatedly extracted 3 times, and the extract is combined; the extract is concentrated under vacuum and reduced pressure to recover the solvent n-hexane solvent (recovery rate is about 80 %) to obtain sea buckthorn seed oil, the yield of sea buckthorn seed oil is 12.98%; after weighing 12.98 g of the sea buckthorn seed oil, add 5 times the volume concentration of 2.5 mol / L ethanol-potassium hydroxide solution, and The saponification liquid was obtained in a water bath at ℃ for 3 hours; after cooling 60 mL of the obtained saponification liquid...

Embodiment 2

[0034] The selected sea buckthorn seeds are washed and aired. After crushing the sea buckthorn seeds, they are passed through a 50-mesh sieve, and they are dried in a constant temperature drying oven at 75°C for 4.5 hours to constant weight; after mixing 100 g of dried sea buckthorn seed powder with 600 mL of n-hexane Soak for 80min, leaching with the aid of ultrasound at 50℃ for 30min. The extract is obtained by suction filtration. The filter residue is extracted 3 times and combined the extract; the extract is concentrated under vacuum and reduced pressure to recover the solvent n-hexane solvent (recovery rate is about 80%) to obtain sea buckthorn seed oil, the yield of sea buckthorn seed oil is 12.91%; after weighing 12.91 g of sea buckthorn seed oil, add 3 times the volume concentration of 2.0 mol / L ethanol-potassium hydroxide solution 30 After cooling, take 40mL of the obtained saponification solution, add 2 times volume of distilled water, 80mL, add saponification solution...

Embodiment 3

[0036] The selected sea buckthorn seeds are washed and aired. After crushing the sea buckthorn seeds, they are passed through a 40-mesh sieve, and dried in a constant temperature drying oven at 70°C for 4 hours to constant weight; the dried 100 g sea buckthorn seed powder is mixed with 400 ml n-hexane and soaked for 30 minutes , Leaching for 20 minutes with the aid of ultrasonic at 40℃, extracting and filtering to obtain the extract, the filter residue is repeatedly extracted 3 times, and the extract is combined; the extract is concentrated under vacuum and reduced pressure to recover the solvent n-hexane solvent (recovery rate is about 80% ) To obtain sea buckthorn seed oil, the yield of sea buckthorn seed oil is 11.41%; 11.41 g of sea buckthorn seed oil is weighed, add 2 times the volume concentration of 1.5 mol / L ethanol-potassium hydroxide solution 20mL, and The saponification liquid was obtained in a water bath at ℃ for 1.5 hours; after cooling 20 mL of the obtained saponif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com