Inclination sensing type storage tank liquid level intelligent detection method and device

An intelligent detection and sensing technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of poor real-time performance, error, wrong signal, etc., and achieve the effect of convenient installation, high precision and convenient instrument maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

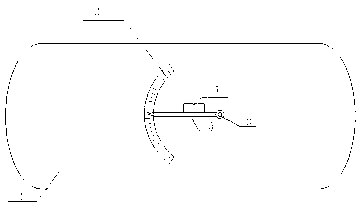

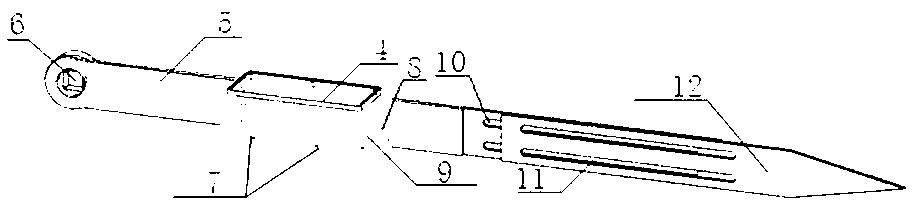

[0020] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

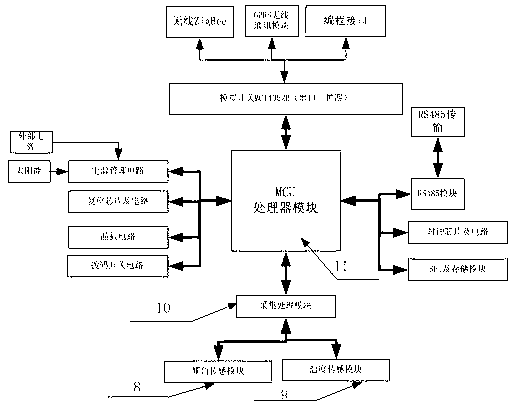

[0021] The method of the invention is realized by an inclination sensor type liquid level gauge, an inclination sensor module, a temperature compensation module, an MCU processor module, an acquisition and processing module, and a data remote transmission module. The working mechanism of the mechanical float pointer liquid level gauge of the storage tank is adopted, and the angle of rotation is measured by the pointer of the inclination sensor type liquid level gauge. One-to-one correspondence, and correct the data through the temperature acquisition module, calculate the liquid level and volume of the storage tank, and transmit the liquid level and volume data through electrical and digital signals; for remote storage tanks that cannot provide power , the liquid level gauge is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com