Surface modification method for polyether sulfone filter membrane

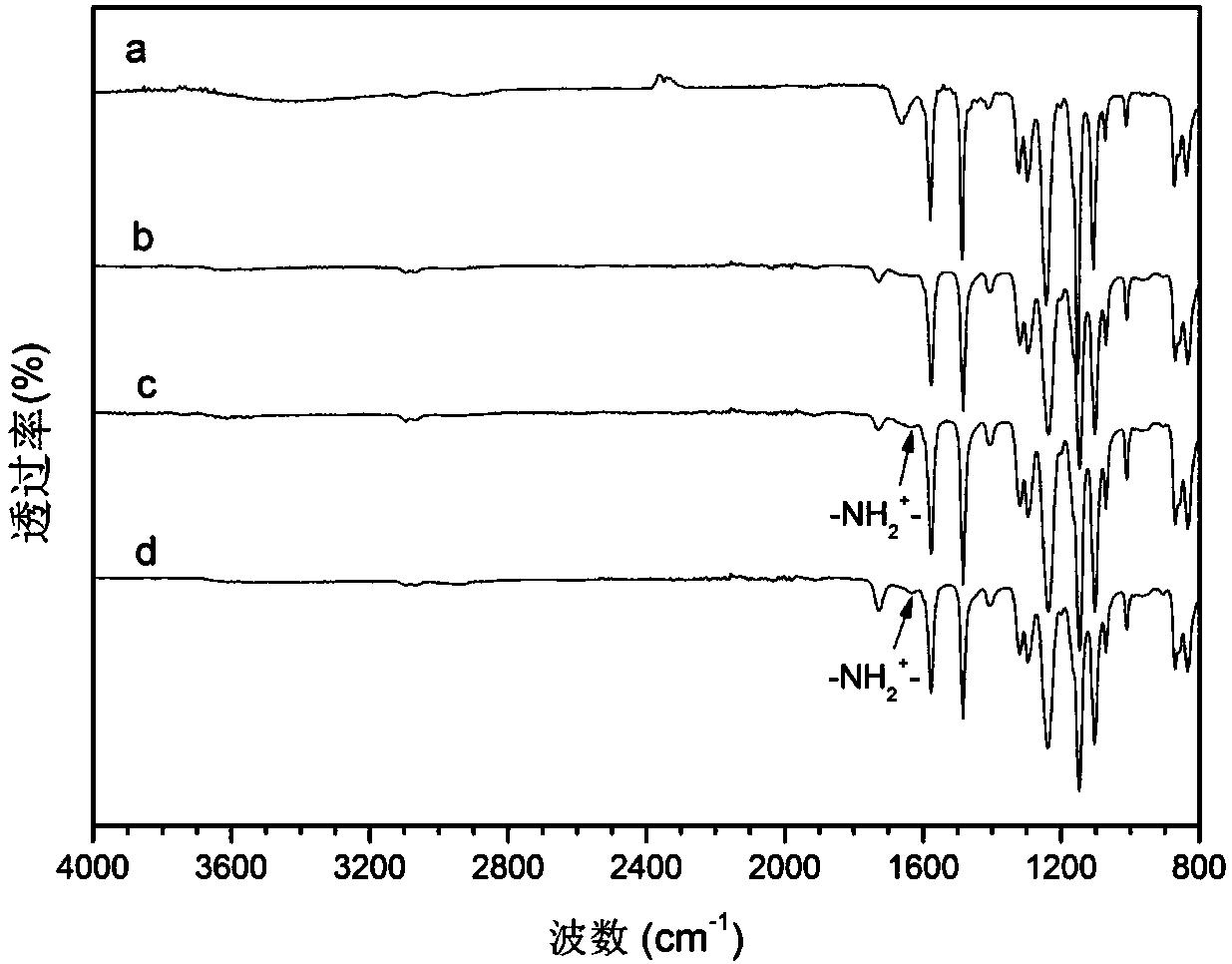

A surface modification, polyethersulfone technology, applied in the field of anti-adhesion polyethersulfone filter membrane modification, can solve the problems of complex preparation method, expensive polyethersulfone sulfonation, harsh process conditions, etc. Improved anti-protein adhesion properties and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A polyethersulfone filter membrane (8 cm x 8 cm) was placed in a plasma chamber (diameter 30 cm, height 20 cm, effective treatment area 10 cm x 10 cm). Vacuum, and then ventilate until the air pressure reaches 0.1 Pa. Turn on the power of the plasma equipment (power 50w, radio frequency 13.56MHz), wait for uniform purple plasma to appear, and treat the film surface for 5min. The filter membrane was allowed to stand in air for 10 min.

[0041] The filter membrane after plasma treatment was immersed in 0.4 mol / L glycidyl methacrylate solution, and the solvent was a mixed solution of water and ethanol (V:V=50:50). Nitrogen was used to remove the air in the reaction system, and then the temperature of the system was raised to 60 degrees centigrade. The temperature was kept constant and the surface-initiated graft polymerization of glycidyl methacrylate was carried out under stirring conditions, and the reaction was terminated after 4 hours. Fully wash with deionized water...

Embodiment 2

[0047] A polyethersulfone filter membrane (8 cm x 8 cm) was placed in a plasma chamber (diameter 30 cm, height 20 cm, effective treatment area 10 cm x 10 cm). Vacuum, and then ventilate until the air pressure reaches 1 Pa. Turn on the power of the plasma equipment (power 50w, radio frequency 13.56MHz), wait for uniform purple plasma to appear, and treat the film surface for 10min. The filter membrane was left to stand in the air for 20min.

[0048] The filter membrane after plasma treatment was immersed in 0.8 mol / L glycidyl methacrylate solution, and the solvent was a mixed solution of water and ethanol (V:V=50:50). Nitrogen was used to remove the air in the reaction system, and then the temperature of the system was raised to 60 degrees centigrade. The temperature was kept constant and the surface-initiated graft polymerization of glycidyl methacrylate was carried out under stirring conditions, and the reaction was terminated after 4 hours. Fully wash with deionized water,...

Embodiment 3

[0052] A polyethersulfone filter membrane (8 cm x 8 cm) was placed in a plasma chamber (diameter 30 cm, height 20 cm, effective treatment area 10 cm x 10 cm). Vacuum, and then ventilate until the air pressure reaches 0.05 Pa. Turn on the power of the plasma equipment (power 50w, radio frequency 13.56MHz), wait for uniform purple plasma to appear, and treat the film surface for 5min. The filter membrane was allowed to stand in air for 10 min.

[0053] The filter membrane after plasma treatment was immersed in 1mol / L glycidyl methacrylate solution, and the solvent was a mixed solution of water and ethanol (V:V=50:50). Nitrogen was used to remove the air in the reaction system, and then the temperature of the system was raised to 60 degrees centigrade. The temperature was kept constant and the surface-initiated graft polymerization of glycidyl methacrylate was carried out under stirring conditions, and the reaction was terminated after 4 hours. Fully wash with deionized water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com