A Strong Shear Annular Jet Cavitation Generator

A technology of annular jets and generators, applied in the direction of chemical/physical/physicochemical nozzle reactors, etc., can solve the problems of poor cavitation effect and weak cavitation intensity, and achieve high cavitation intensity and strong cavitation effect , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

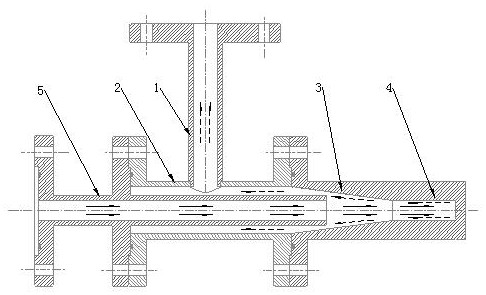

[0019] A strong shear annular jet cavitation generator, comprising a high-pressure water supply pipe 1, an outlet pipe 5 connected coaxially and communicated in sequence, a rectifying pipe 2, a tubular contraction section 3, and a back pressure chamber 4; the high-pressure water supply pipe 1 is in vertical communication with the rectification tube 2; the outer diameter of the outflow tube 5 is smaller than the inner diameter of the rectification tube 2; one end of the back pressure chamber 4 communicates with the constriction section 3, and the other end is closed.

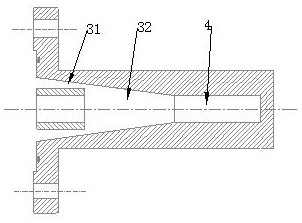

[0020] The tubular contraction section 3 is coaxially connected with the outlet pipe 5, and the inner wall of the contraction section 3 and the periphery of the outlet pipe 5 form a tapered annular cavity, which is an annular nozzle 31. The area ratio of the cross section is 0.25-0.5.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com