A kind of cavitation generator with special-shaped flow channel

A technology of generator and annular flow channel, which is applied in the directions of fluid mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low cavitation efficiency, achieve enhanced turbulent flow intensity, drop water supply pressure, and enhance air flow. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

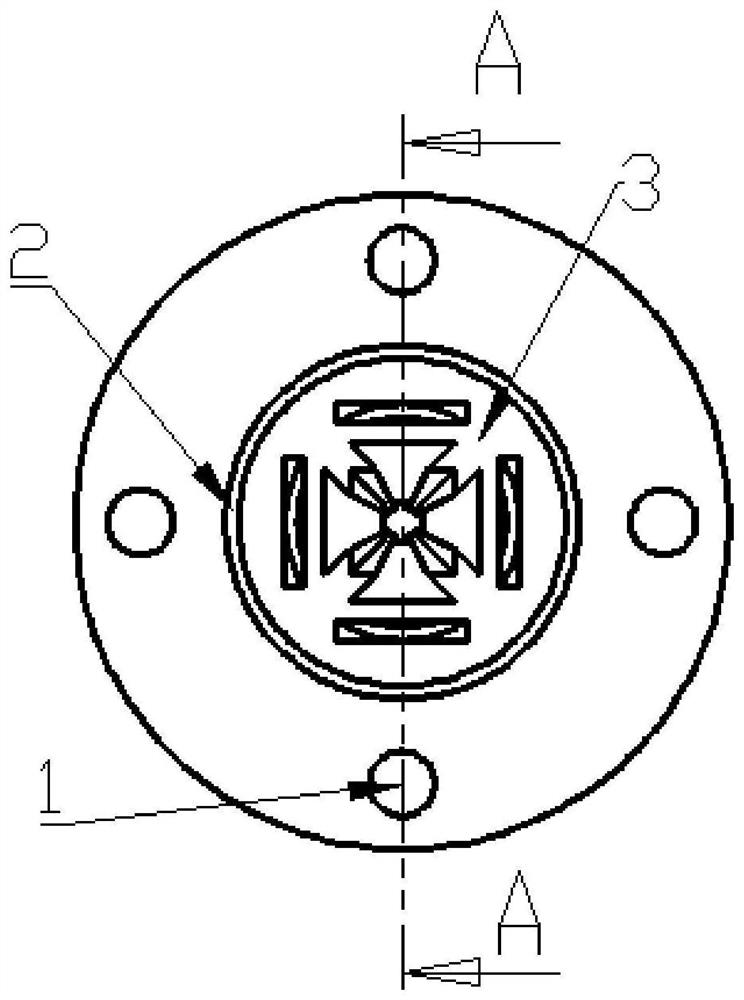

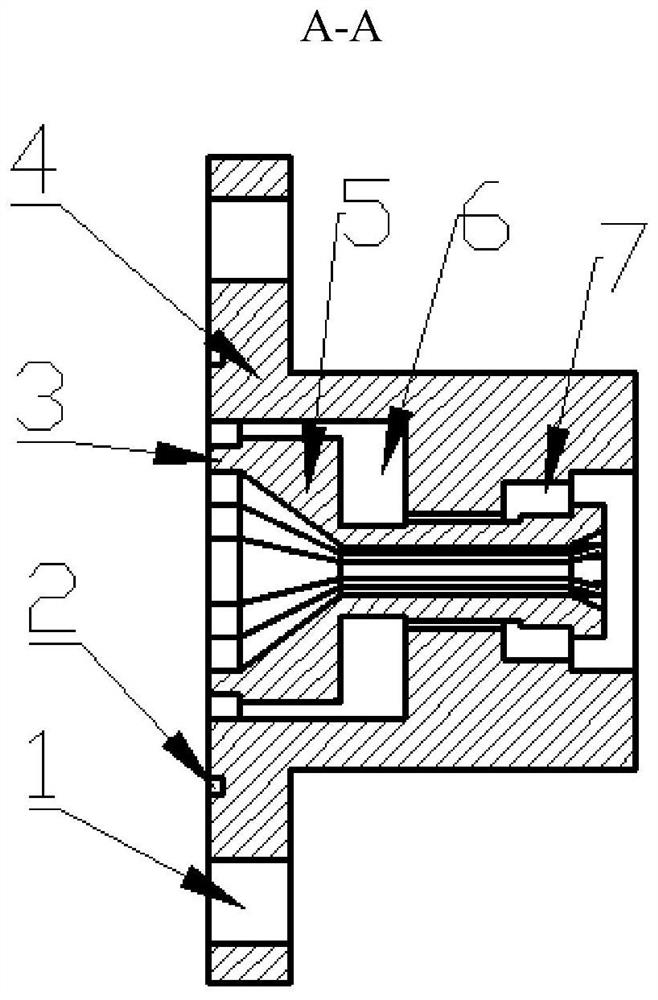

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. Such as Figure 1-9 As shown, a cavitation generator with a special-shaped flow channel includes a connecting block 3, an outer tube 4 and an inner tube 5, and an annular flow channel is formed between the outer tube 4 and the inner tube 5, and the center of the inner tube 5 It is the central flow channel; the outer tube 4 and the inner tube 5 form a whole double flow channel through the connecting block 3, and the whole double flow channel is printed by 3D printing technology;

[0032] The central flow passage is composed of an inlet section, a tapering section, a holding section and a diverging section, and the cross section of the central flow passage is an irregular polygon;

[0033] The annular flow channel is a stepped flow channel in the axial direction and consists of two deceleration chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com