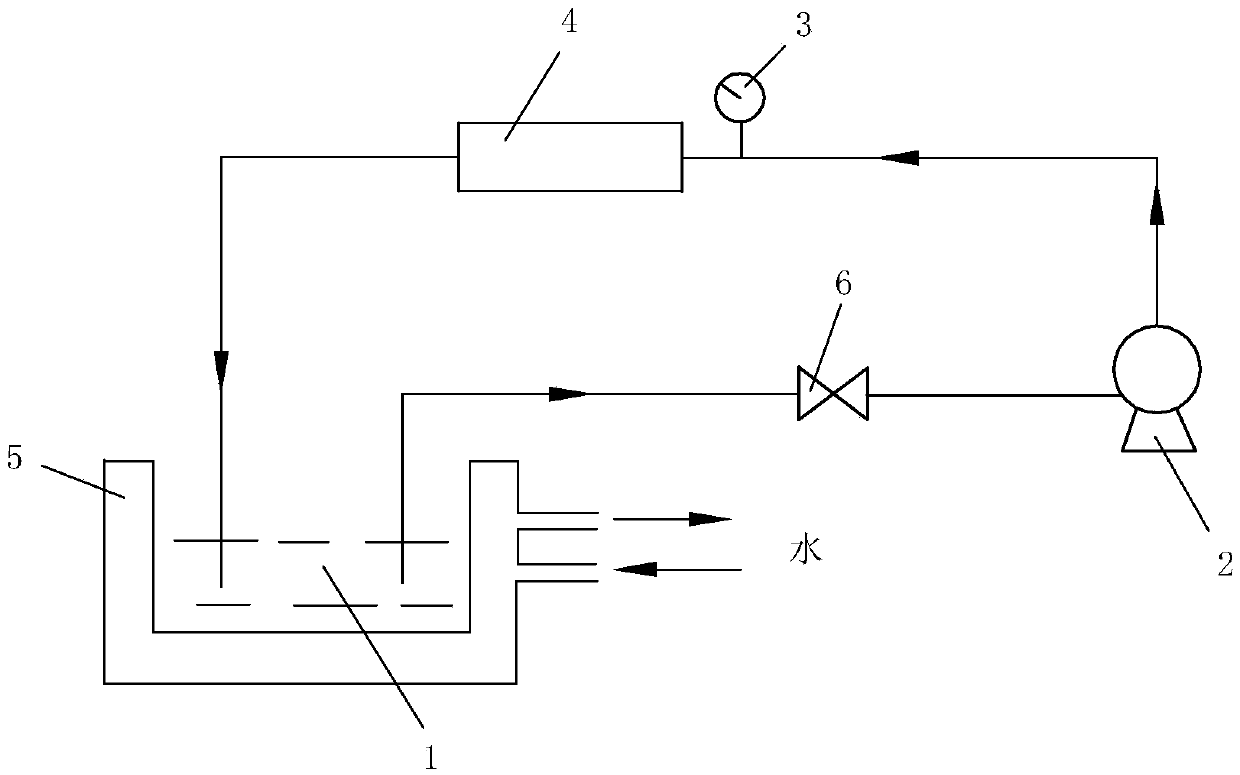

Method for preparing chitosan oligosaccharide by utilizing ultrasonic-hydraulic collaborative cavitation

A technology of chitosan oligomerization and hydrodynamic cavitation is applied in the field of preparation of chitosan oligomerization method, which can solve the problems of energy waste, weakening, unfavorable heat-sensitive material treatment, etc., and achieve the effects of high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of method utilizing ultrasonic-hydraulic cooperative cavitation to prepare chitosan oligosaccharides comprises the following steps:

[0037] The first step: dissolving chitosan: adding high-molecular-weight chitosan into a solvent and dissolving it to form a chitosan solution, the solvent being one of an aqueous solution of inorganic acid, an aqueous solution of organic acid or a slightly acidic buffer solution, Wherein, the mass concentration of the described inorganic acid aqueous solution or organic acid aqueous solution is 1%-13%, the pH of the buffer solution is 3-5, and the mass concentration of the chitosan solution is 1g / L-10g / L, the relative molecular mass of the high molecular weight chitosan is greater than 2×10 6 , the degree of deacetylation is greater than 60%; the inorganic acid is hydrochloric acid, the organic acid is formic acid, acetic acid, lactic acid or citric acid, and the buffer solution is acetic acid-sodium acetate or citr...

Embodiment 2

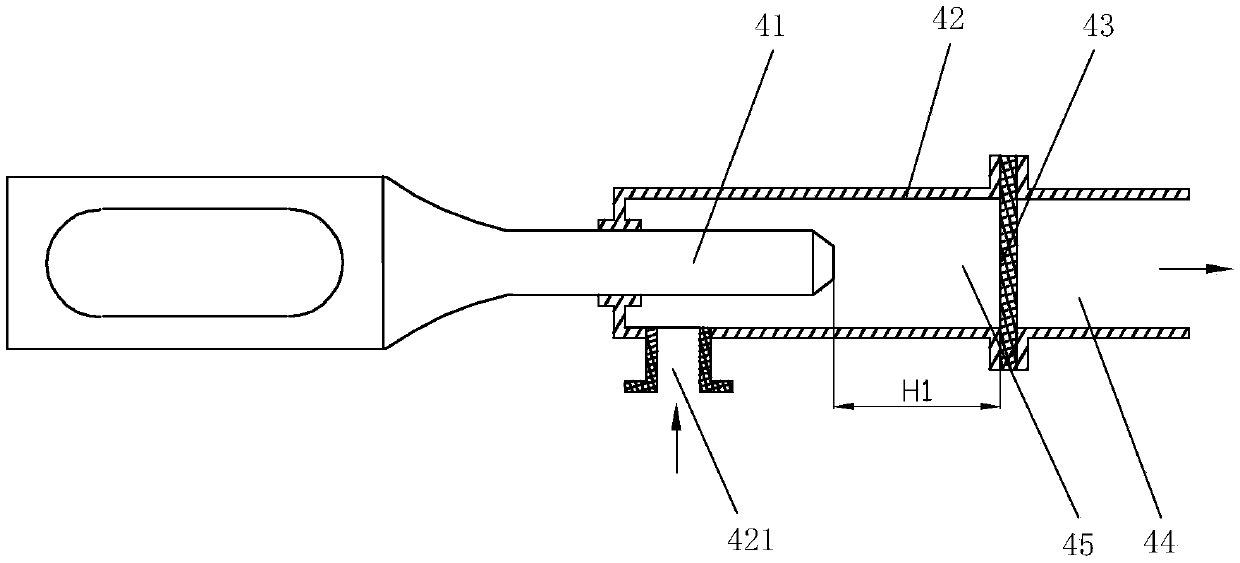

[0052] Embodiment 2: a kind of method utilizing ultrasonic-hydraulic synergistic cavitation to prepare chitosan oligosaccharide, it is basically the same as embodiment 1, difference is: the structure of ultrasonic-hydraulic cavitator is different, the described in this embodiment Ultrasonic-hydrodynamic cavitator4 (eg Figure 4 (shown) is composed of an ultrasonic transducer 41 and a hydraulic cavitation device, and the ultrasonic transducer extends into the hydraulic cavitation device to generate ultrasonic waves. The hydraulic cavitation device is a Venturi tube 46, and the Venturi tube is followed by an inlet section 461, a contraction section 462, a throat 463, a diffusion section 464 and an outlet section 465 along the material flow direction, and the inlet section 461 has a material inlet 466, The ultrasonic transducer extends into the inlet section, the ratio of the angle α of the contraction section to the angle β of the divergence section is 0.5~2, and the ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com