Patents

Literature

33results about How to "Has large-scale industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing grapheme dispersion liquid

ActiveCN104772064AShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

The invention discloses a method for preparing grapheme dispersion liquid. The method comprises the following steps: (1) uniformly mixing grapheme and a dispersant in a solvent to obtain a uniformly mixed solution; and (2) dispersing the uniformly mixed solution by a dispersing device for 0.5-24 hours to obtain the grapheme dispersion liquid, wherein the rotation speeds of a high shearing dispersion head and a colloid grinding disc are regulated to be within 100-14000rpm, the rotation speed of an electric mixer is at 10-2000rpm, an energy-concentration ultrasonic probe is additionally arranged, the ultrasonic frequency is within 20-80kHz and the dispersion temperature is 0-20 DEG C after being regulated by a cooling system. According to the method for preparing the grapheme dispersion liquid, the dispersion time is saved and the production efficiency is improved due to the adoption of multiple dispersion methods and synergic action, the cost is low, the operation is easy, and the method is nontoxic, free of pollution and beneficial for batch production, has high dispersion stability and a bright prospect of large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

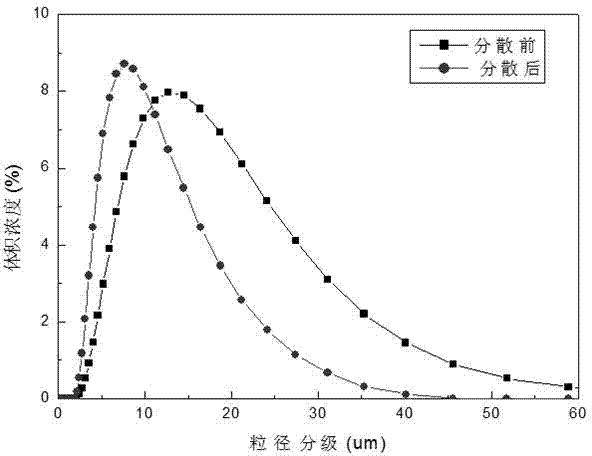

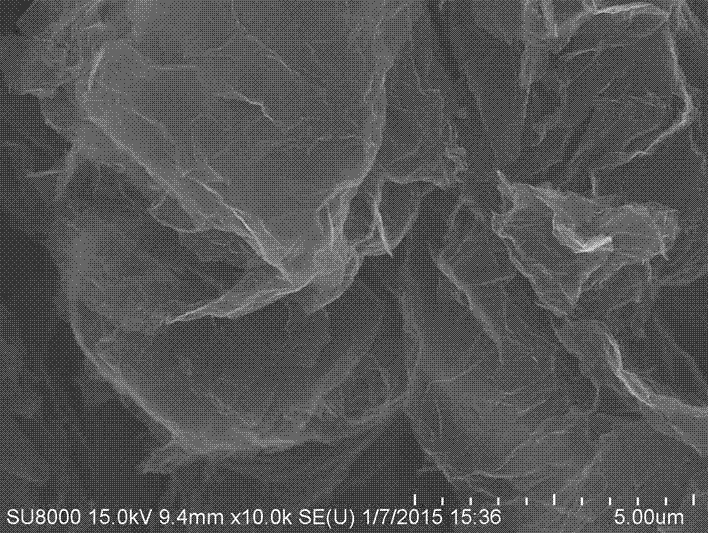

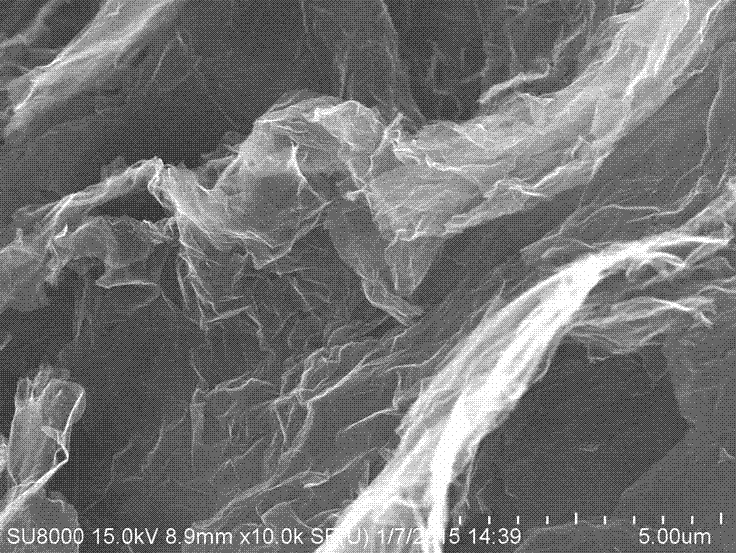

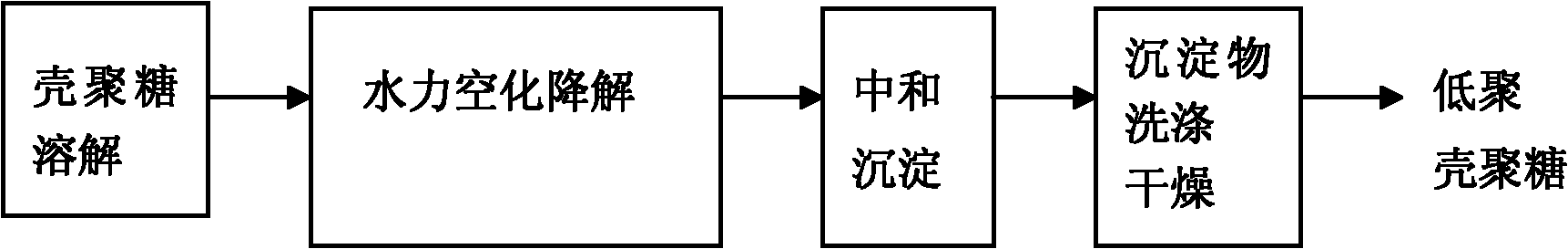

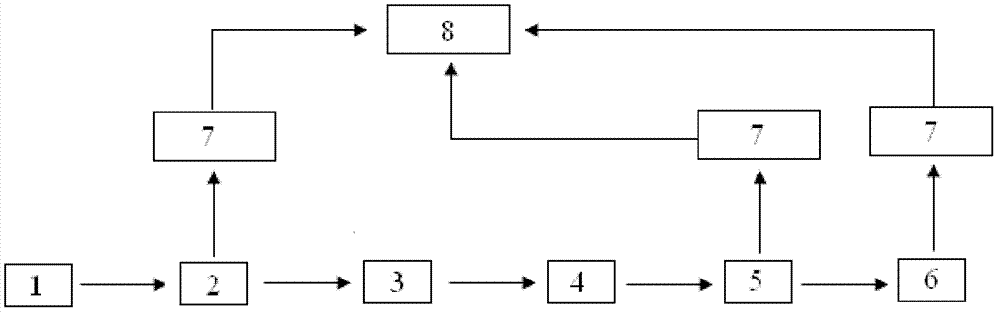

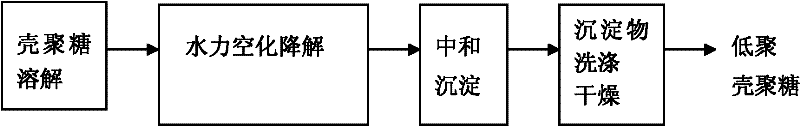

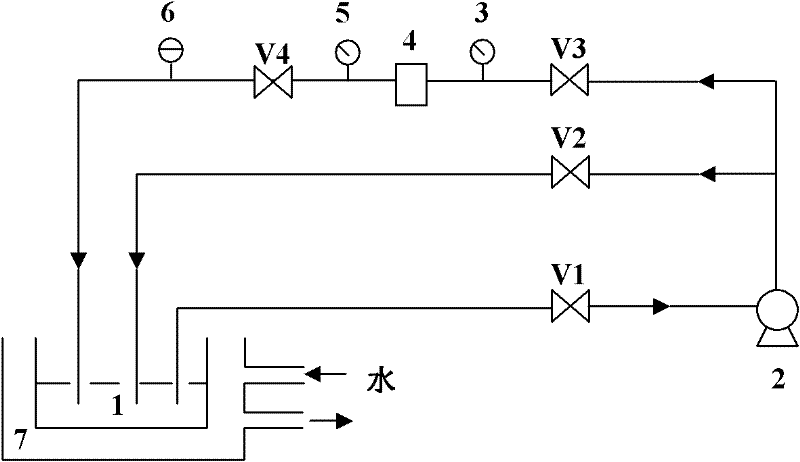

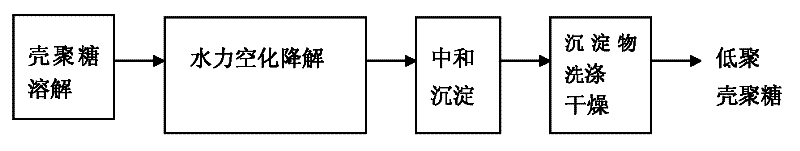

Preparation method of oligochitosan

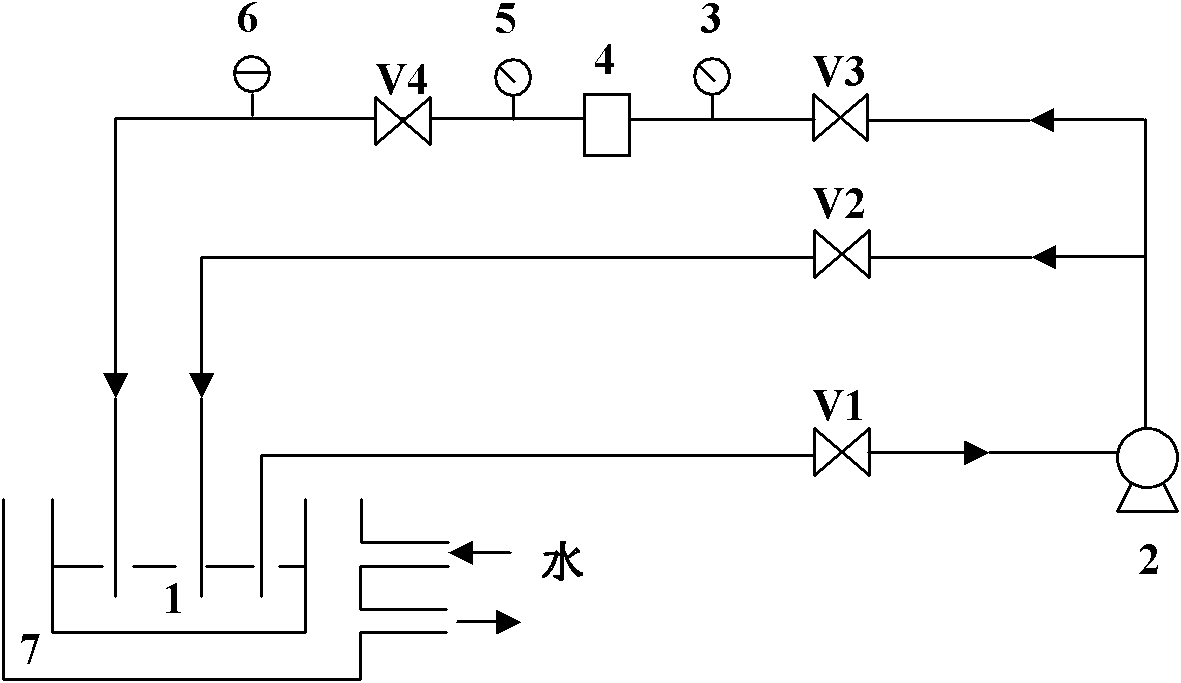

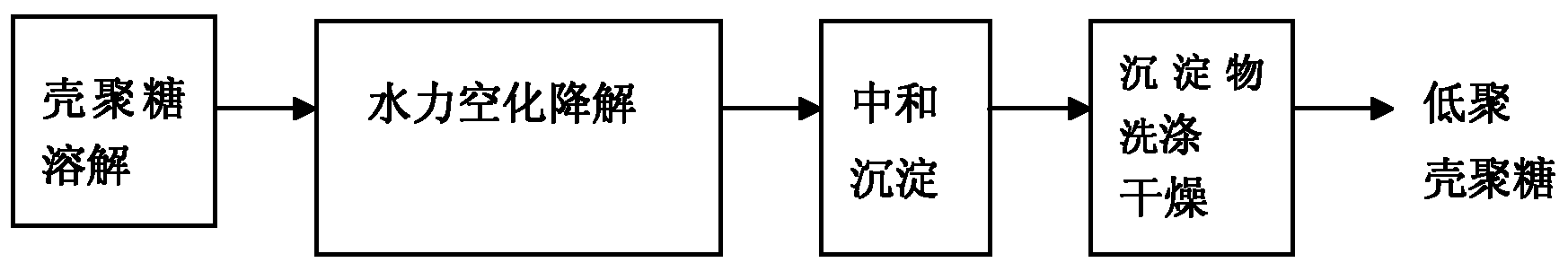

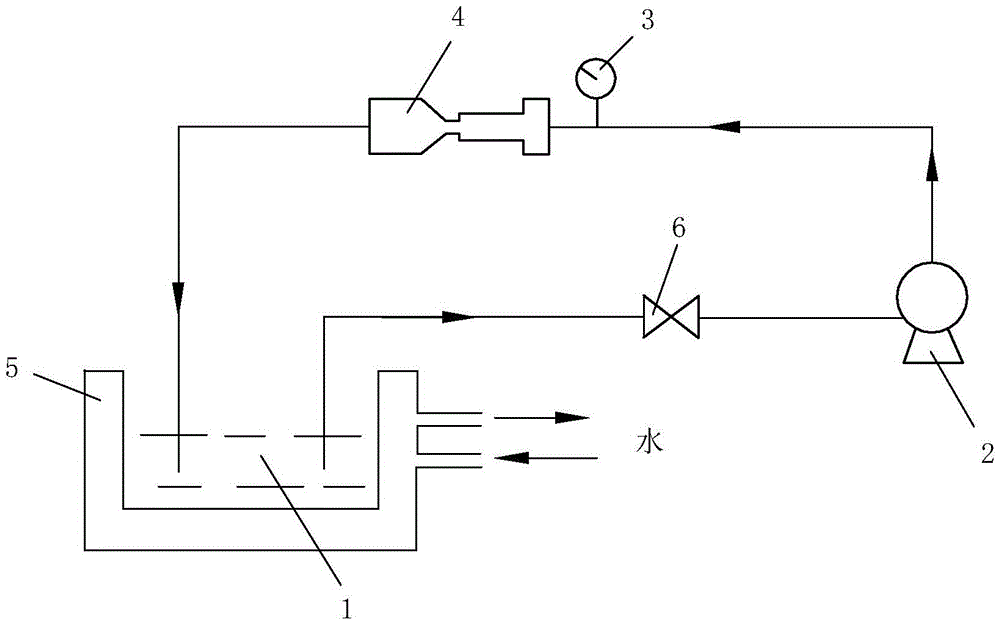

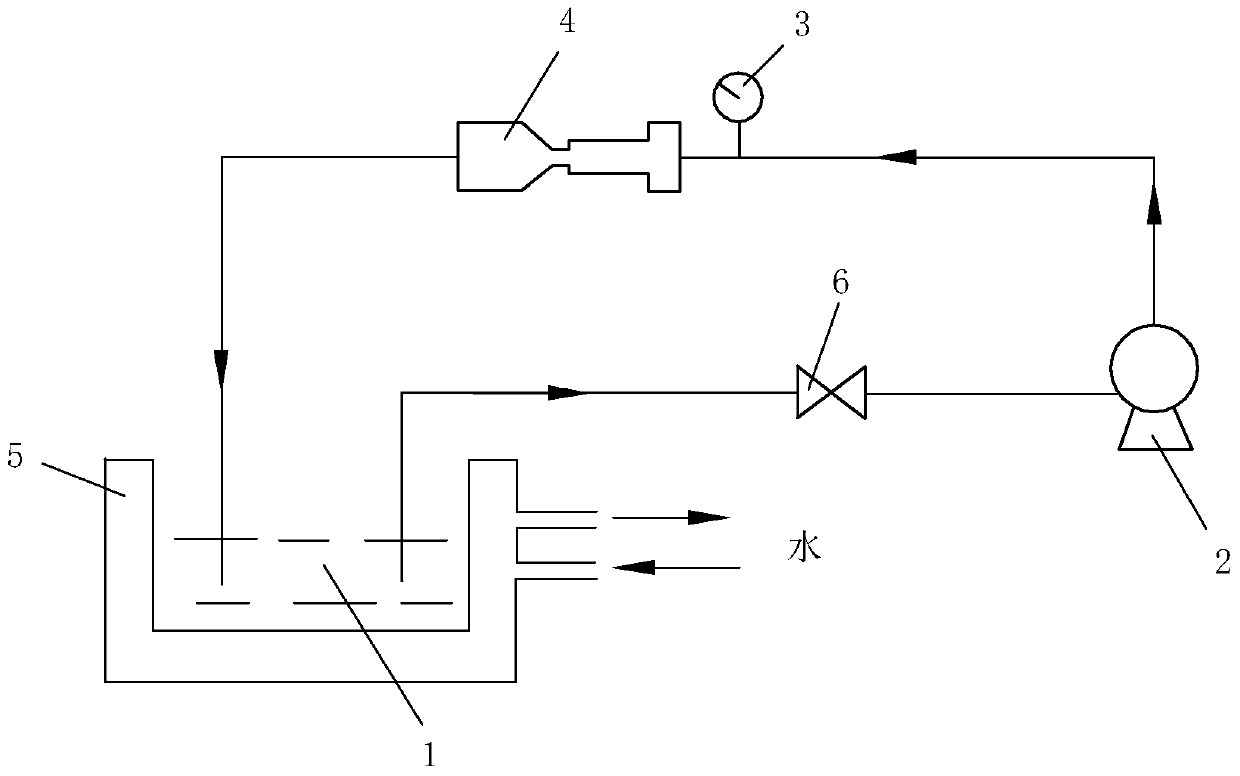

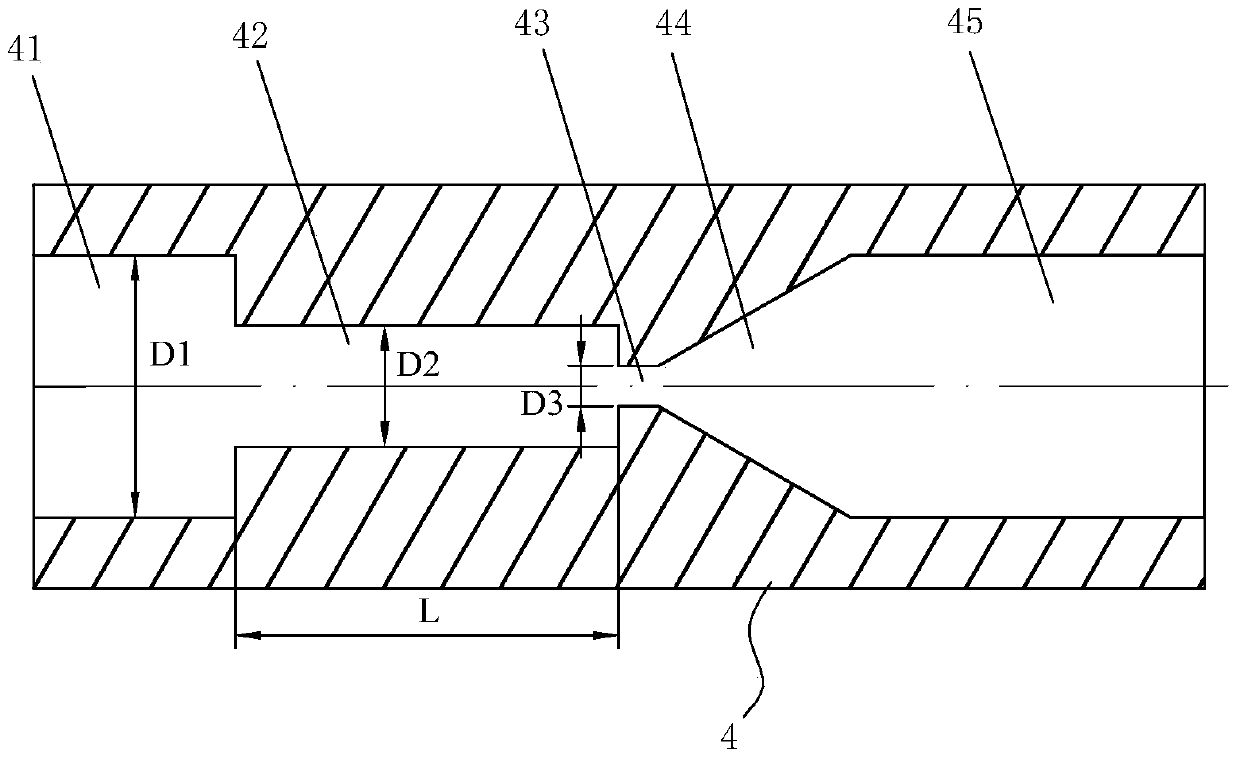

The invention relates to a preparation method of oligochitosan. The oligochitosan is prepared through degradation of chitosan under hydraulic cavitation of chitosan solution. The preparation method comprises the following steps: dissolving the chitosan, carrying out hydraulic cavitation and degradation, adding alkali solution into the chitosan solution after degradation to adjust the pH, washing precipitates, carrying out vacuum drying and the like. The process of hydraulic cavitation and degradation comprises the following steps: placing the chitosan solution into a storage tank, maintaining a constant temperature through a circulating water tank, delivering the chitosan solution to a cavitation device for cavitation and degradation through a pump, adjusting the pressure of the upstream inlet with a valve V1, a valve V2, a valve V3 and a valve V4, restoring the pressure and flow of the downstream, monitoring the pressure and flow with a pressure gauge and a flow meter, making the solution after cavitation and degradation flow back to the storage tank, controlling the temperature to be 25-80 DEG C through the circulating water tank, and carrying out the circulating process in the hydraulic cavitation device for 0.5-20 hour(s) until the oligochitosan satisfies the requirements for the relative molecular mass. The method has the advantages of simple and convenient operation, low energy consumption, high efficiency and the like.

Owner:WUHAN NORJAN BIOLOGICAL TECH

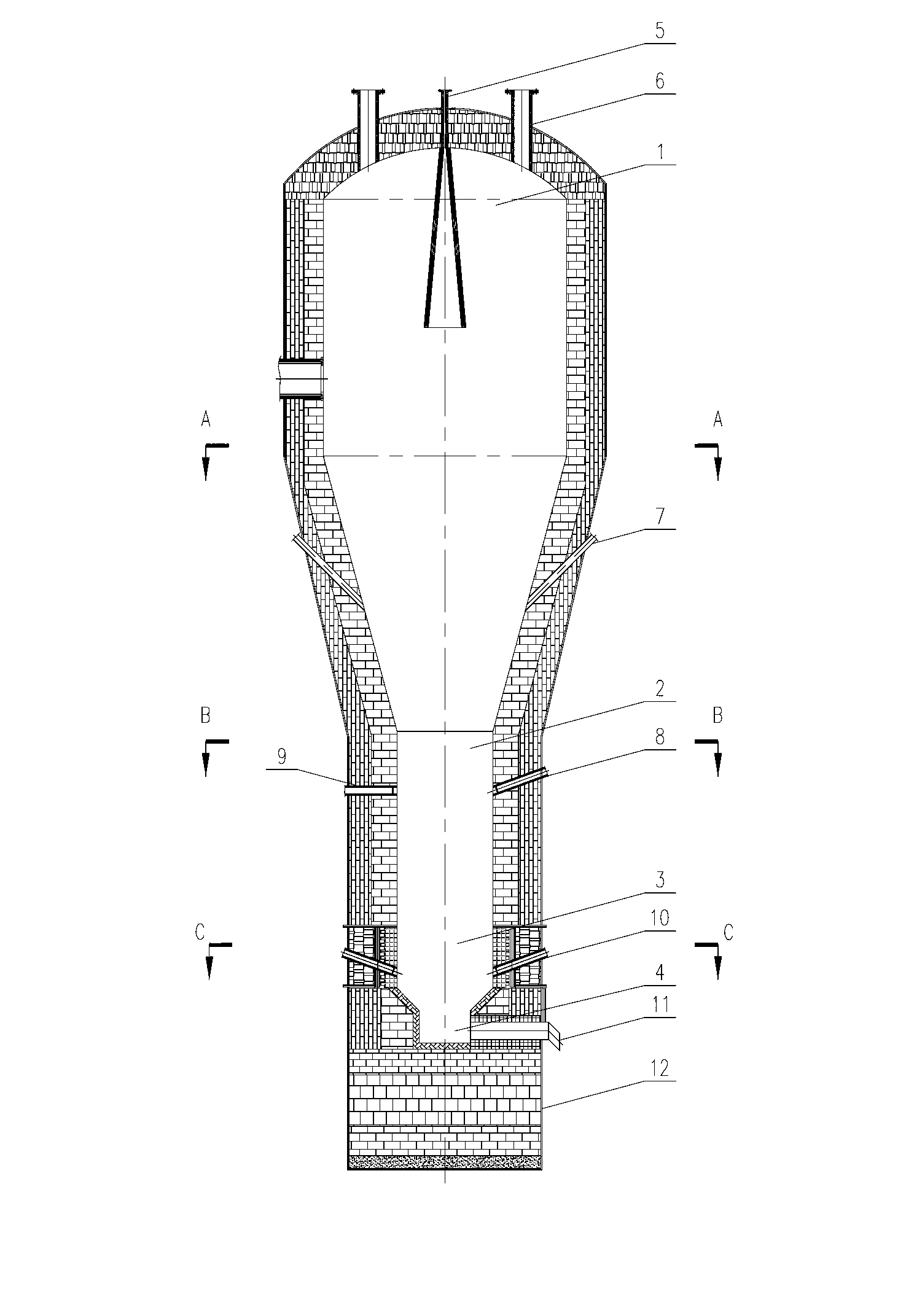

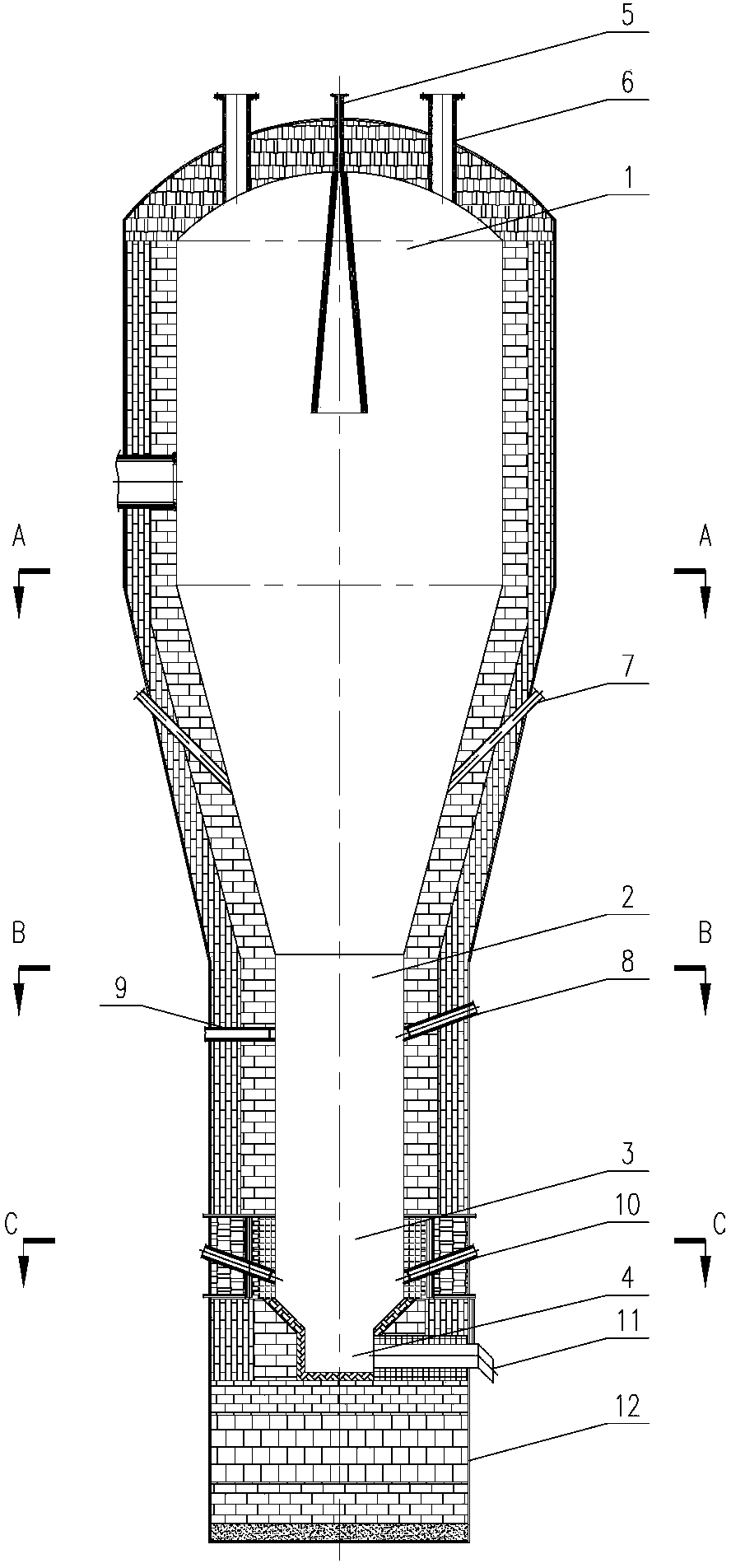

Method for preparing calcium carbide and synthetic gas via flameless oxidation heating method, and calcium carbide reactor

ActiveCN103011164AExtended service lifeIncrease reaction rateCalcium carbideFixed-bed gasificationMixed gasInternal heating

The invention discloses a method for preparing calcium carbide and a synthetic gas via a flameless oxidation heating method, and a calcium carbide reactor, and solves problems of influencing time and effect of calcium carbide reaction caused by uneven heat distribution of the calcium carbide and the synthetic gas prepared by a conventional method and non-uniform particle size of materials entering a reaction chamber. In the method, flameless combustion in the reaction chamber is realized by controlling oxygen content in a mixed gas passing into the reaction chamber; and problems of non-uniform particle size of materials in the reaction chamber is solved by designing feeding particle size at two feeding ports. The reactor enables heat distribution in the chamber to be more uniform through the improvement of oxygen burners of the reaction chamber and a vaporizing chamber. The method is simple in process, is safe and reliable, has more uniform heat distribution, high calcium carbide reaction efficiency and high calcium carbide purity, low loss to furnace walls, the content of the generated synthetic gas is over 7 times that a conventional electrothermal method, and at the same time, consumption rate of raw materials and fuels is low.

Owner:WUHUAN ENG

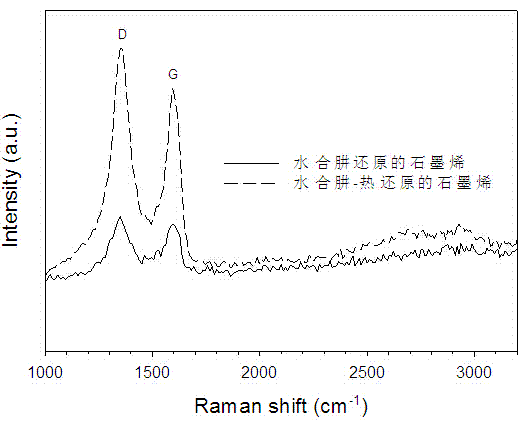

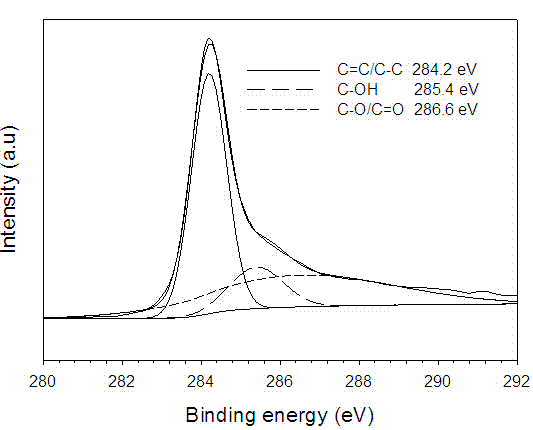

Metal-solution reduction method for preparing graphene

The invention particularly relates to a metal-solution reduction method for preparing graphene. A graphene oxide water solution with low concentration is subjected to reduction treatment by a compound reduction system of iron powder and hydrochloric acid, so as to prepare graphene powder. The graphene oxide water solution with low concentration is subjected to reduction treatment by the compound reduction system of metal iron powder and hydrochloric acid, so that the metal-solution reduction method is low in raw material cost, nontoxic, easy to operate, and beneficial to mass production, and has a wide large-scale industrial application prospect. According to the metal-solution reduction method, a dilute solution is adopted, so that the whole reaction process is small in influence on the environment; liquid waste only contains a few of ions, so that the treatment cost is low.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

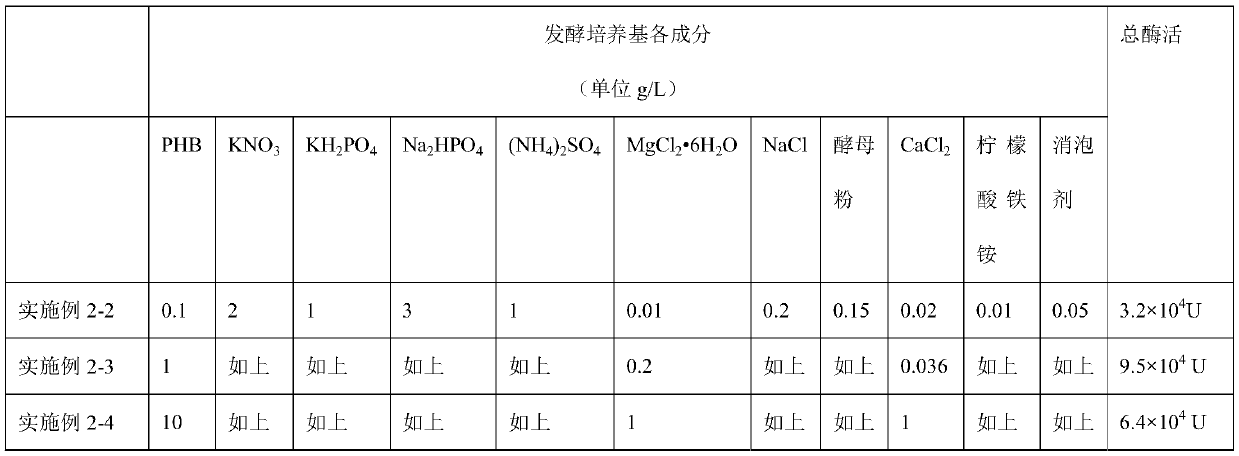

Method for producing high-purity (R)-(-)-3-hydroxybutyric acid by adopting enzymatic method

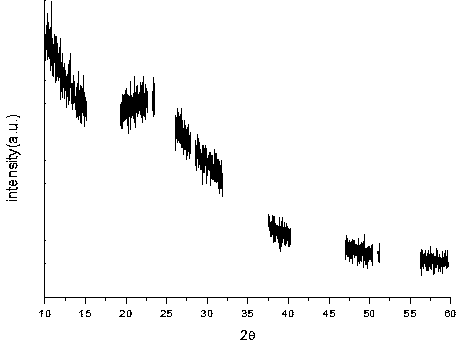

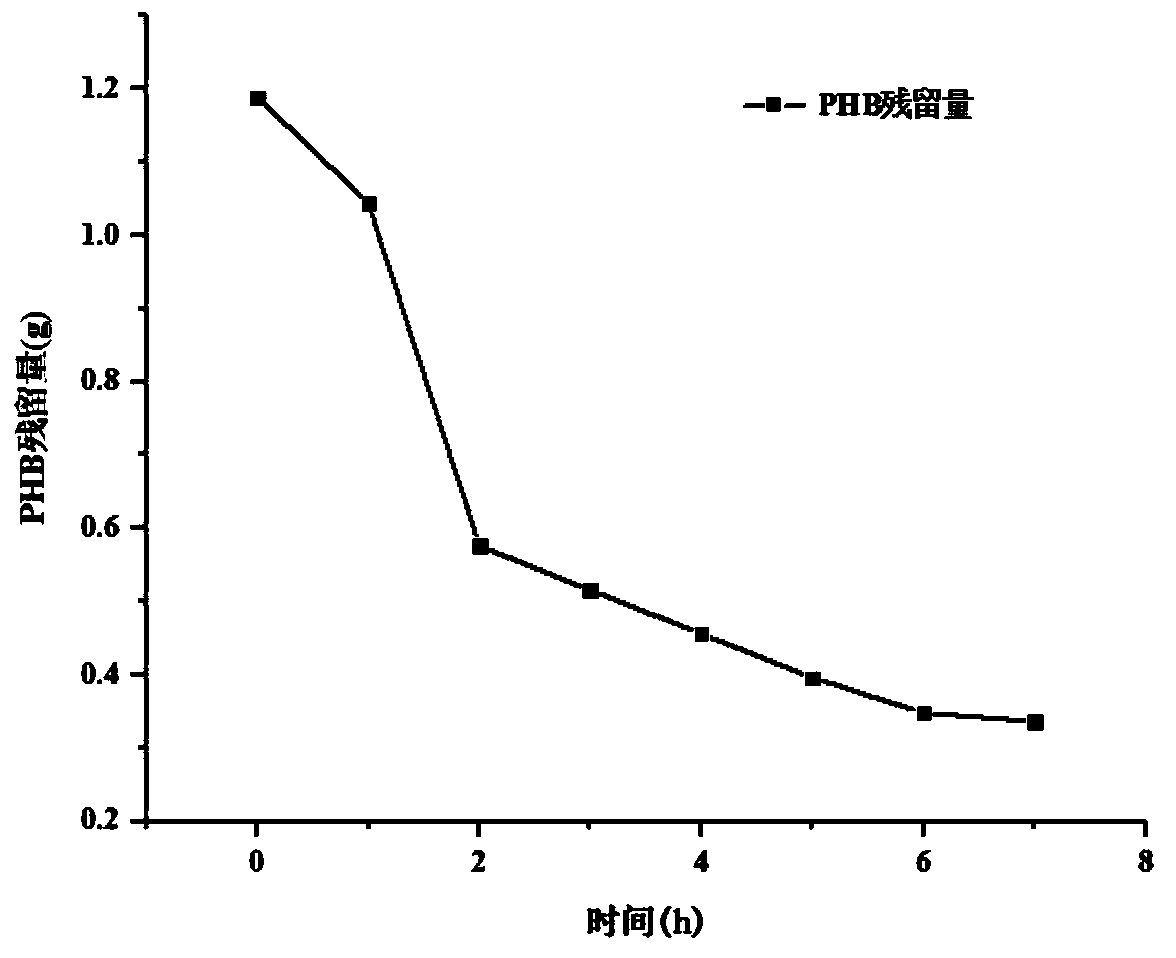

InactiveCN110904161AReduce generationHigh chemical purityHydrolasesMicroorganism based processesHydroxybutyric acidHydroxy group

The invention discloses a method for producing high-purity (R)-(-)-3-hydroxybutyric acid by adopting an enzymatic method. Compared with a chemical method and a whole-cell fermentation method, the method disclosed by the invention has the advantages of mild reaction conditions, less waste liquid generation, high chemical purity of (R)-(-)-3-hydroxybutyric acid, single optical activity and the like.As the components of a culture medium for producing (R)-(-)-3-hydroxybutyric acid by the enzyme method are much simpler than those of the culture medium produced by a whole-cell fermentation method,the product separation cost is greatly reduced, and the purity is higher. According to the method, Diaphorobacter polyhydroxybutyrativorans bacteria are adopted to generate the PHB depolymerizing enzyme in a specific culture environment, and meanwhile, the PHB is used as a carbon source and an inducer for enzymolysis, so that the catalytic efficiency of the enzyme is extremely high.

Owner:ZHEJIANG ENMAT BIOLOGICAL TECH CO LTD

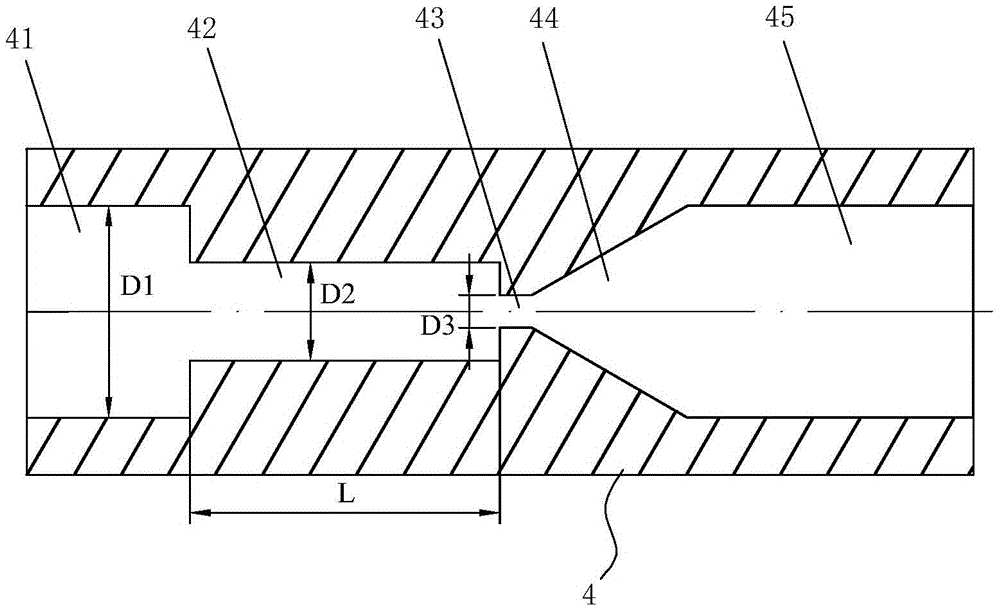

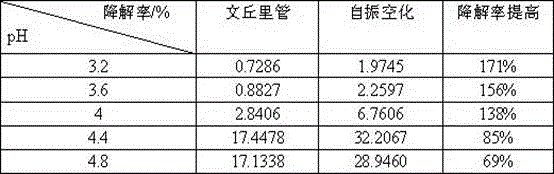

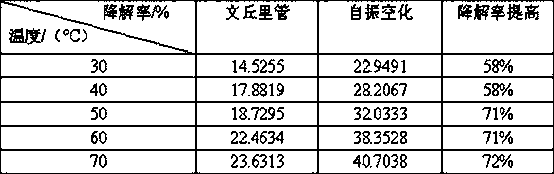

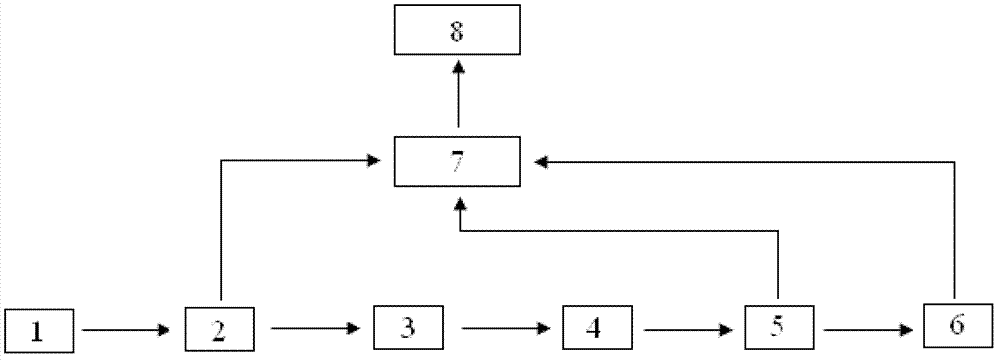

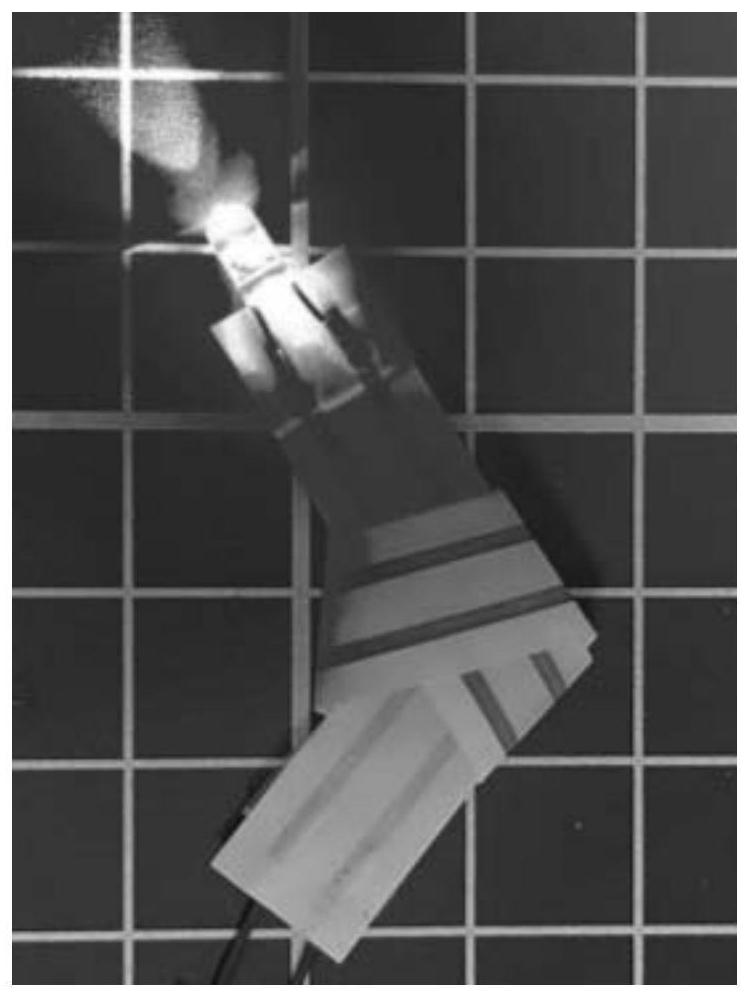

Method for preparing oligochitosan through self-resonating cavitation

The invention relates to a method for preparing oligochitosan through self-resonating cavitation. The method is characterized in that self-resonating cavitation degradation is adopted, that is, a chitosan solution is subjected to self-resonating cavitation degradation treatment in a self-resonating cavitation device; the self-resonating cavitation device comprises a thermostatic water-bath circulation water tank, a storage tank, a pump, a self-resonating cavitation device, a pipeline for conveying the chitosan solution, a pressure gauge and a valve; the technological process of self-resonating cavitation degradation is as follows: the chitosan solution is stored in the storage tank, subjected to thermostatic treatment by the circulation water tank and conveyed by the pump to the self-resonating cavitation device for cavitation degradation, the pressure of an inlet is adjusted by the valve, the pressure is monitored by the pressure gauge, and the chitosan solution subjected to cavitation degradation flows back to the storage tank. The degradation rate by using the method is at least 40% higher than that by using a hydrodynamic cavitation device (venturi tube) to prepare oligochitosan at present, and the method has the characteristics of simplicity, easiness, low energy consumption, high efficiency and the like and has the advantage of mass industrial application.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A stable and transparent superhydrophobic or superamphiphobic coating and its preparation method and application

The invention belongs to the field of super-amphiphobic materials, and discloses a stable and transparent super-hydrophobic or super-amphiphobic coating as well as a preparation method and the application thereof. The preparation method for the coating comprises the steps as follows: blending nanoparticles, epoxy resin with a solvent to obtain the epoxy resin hybridization solution; dissolving fluorine-containing substances and a catalyst into a solvent to obtain the fluorine-containing solution; spraying the epoxy resin hybridization solution on the surface of a substrate, drying the substrate for 0.5-5 h at the temperature of 80-130 DEG C, spraying the fluorine-containing solution on the surface of the substrate, drying the substrate for 0.5-5 h at the temperature of 80-130 DEG C after the solvent is volatilized, and finally washing the surface of the substrate by using the solvent, so as to obtain the stable and transparent super-hydrophobic or super-amphiphobic coating. The super-hydrophobic or super-amphiphobic coating can be applied to hydrophobic and oleophobic modification of surfaces of the vast majority of substrates.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

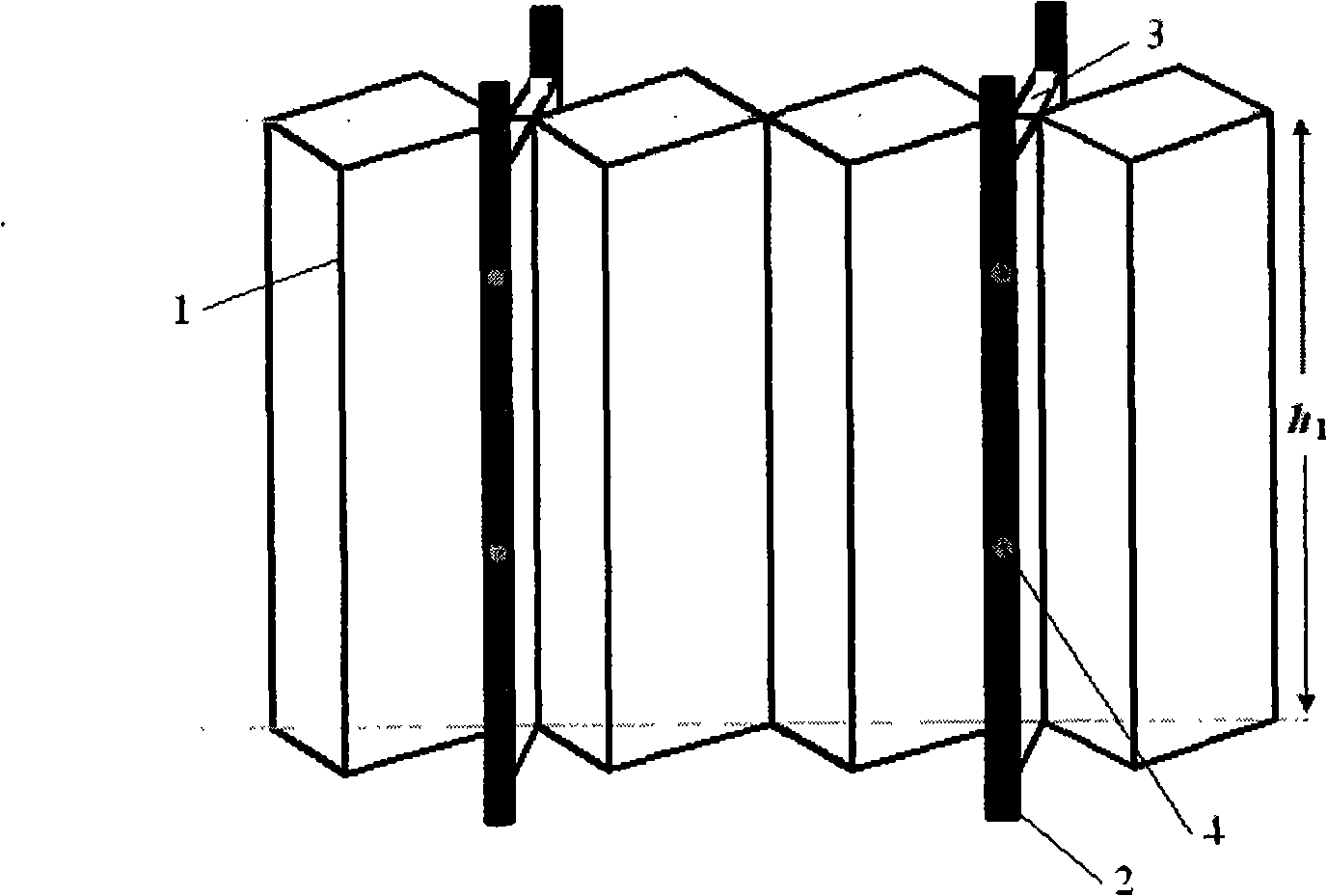

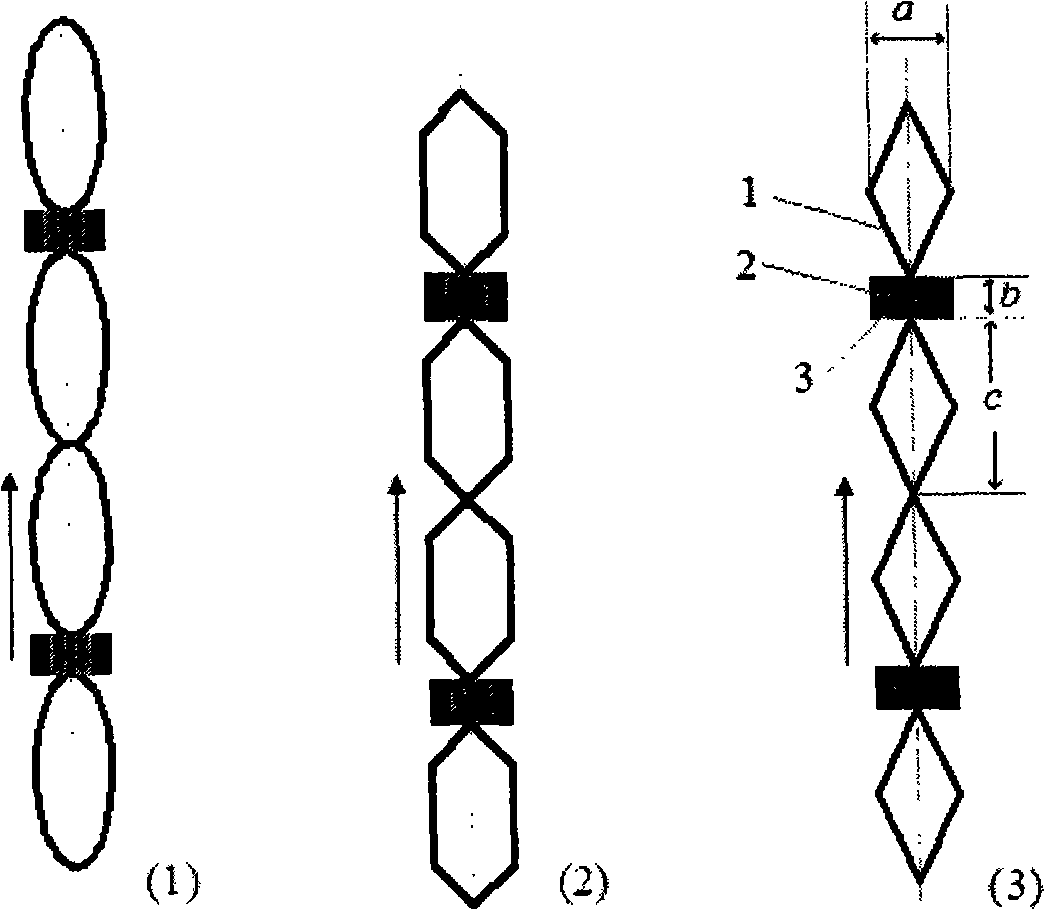

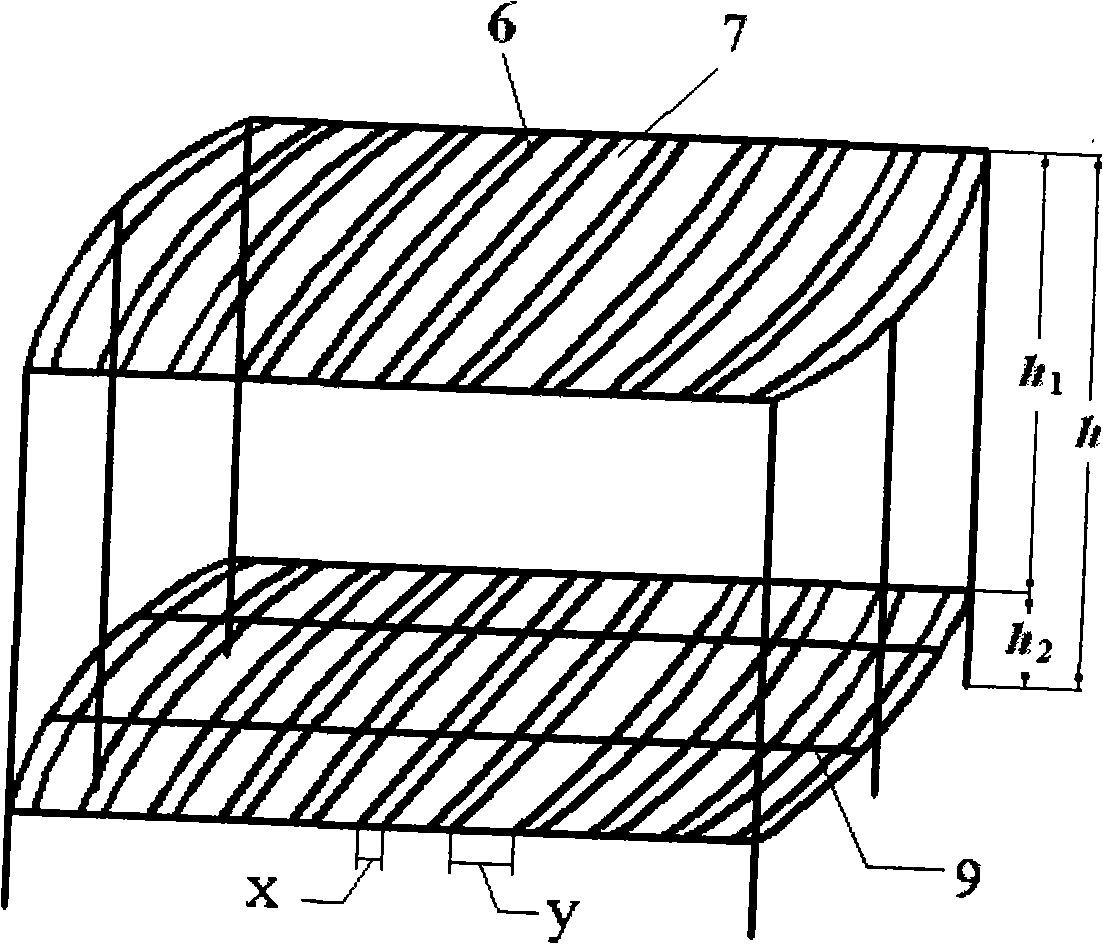

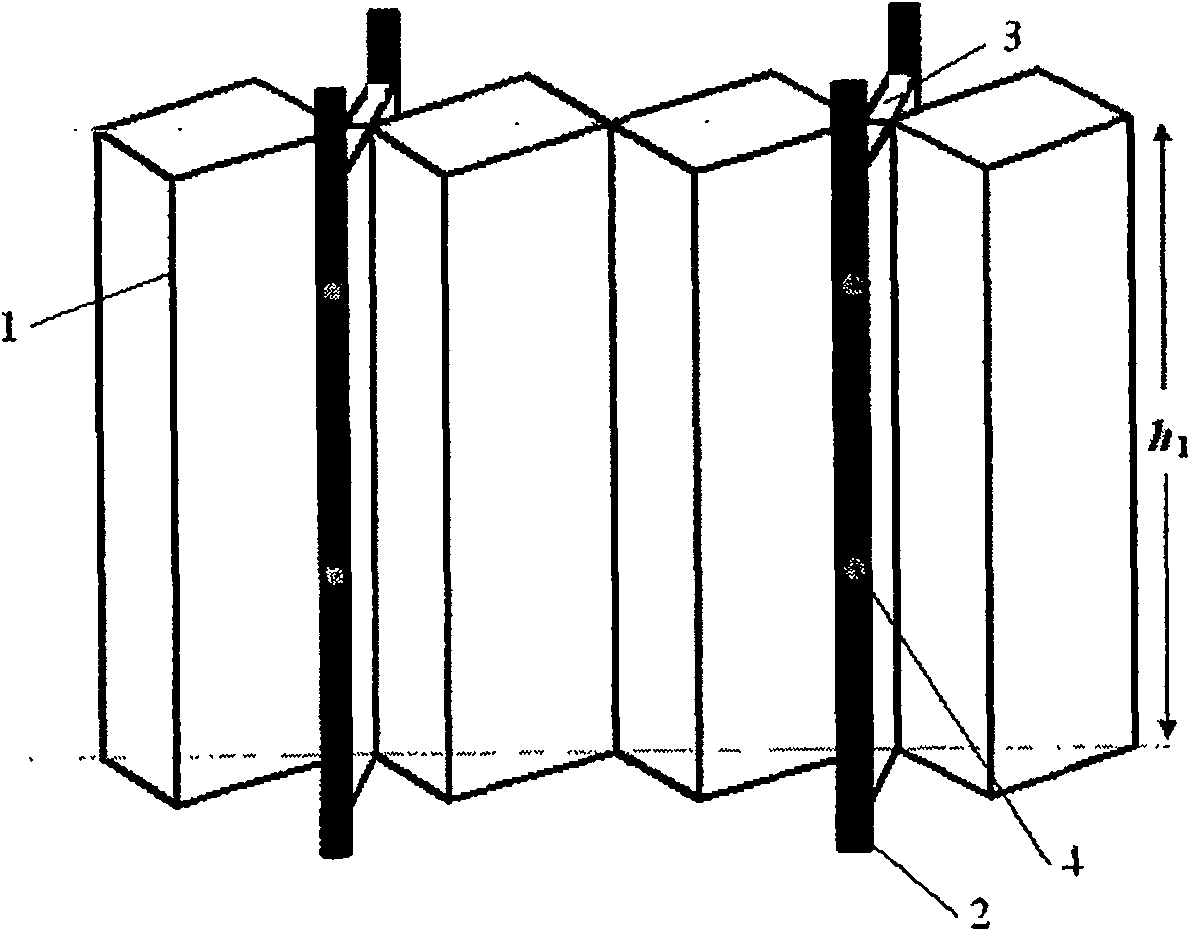

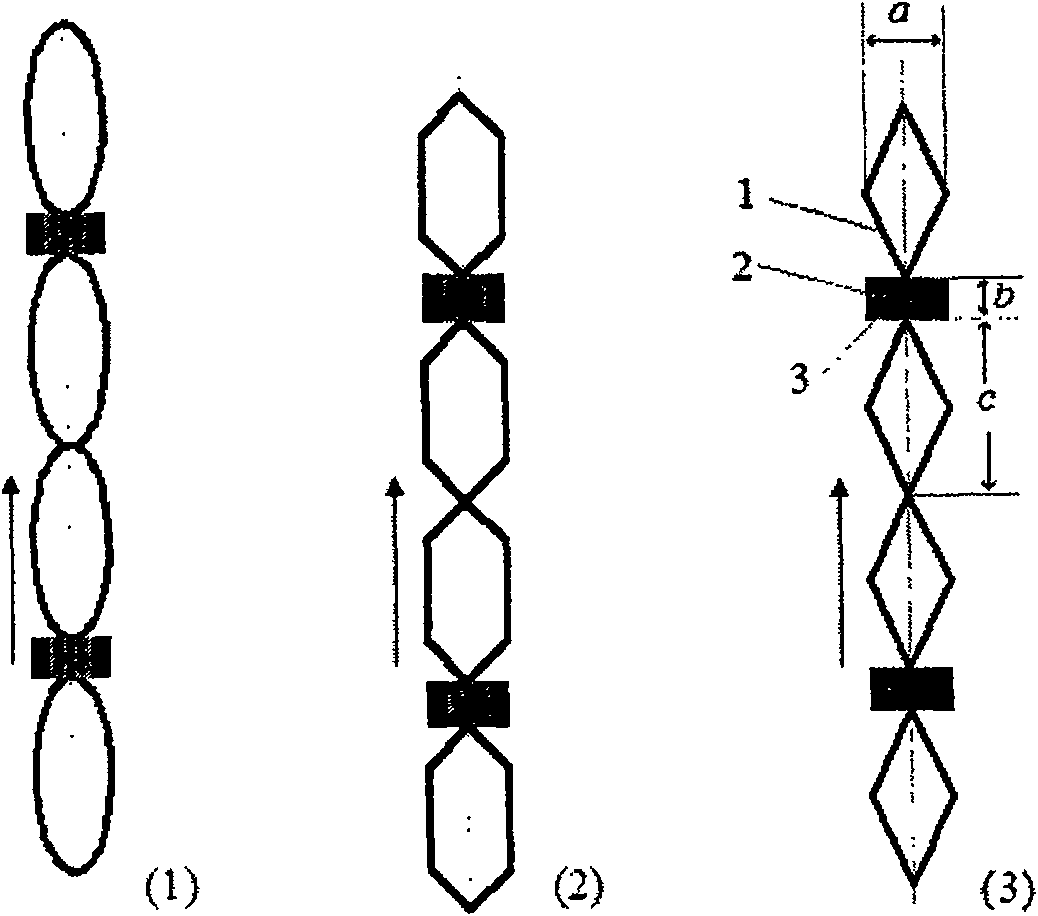

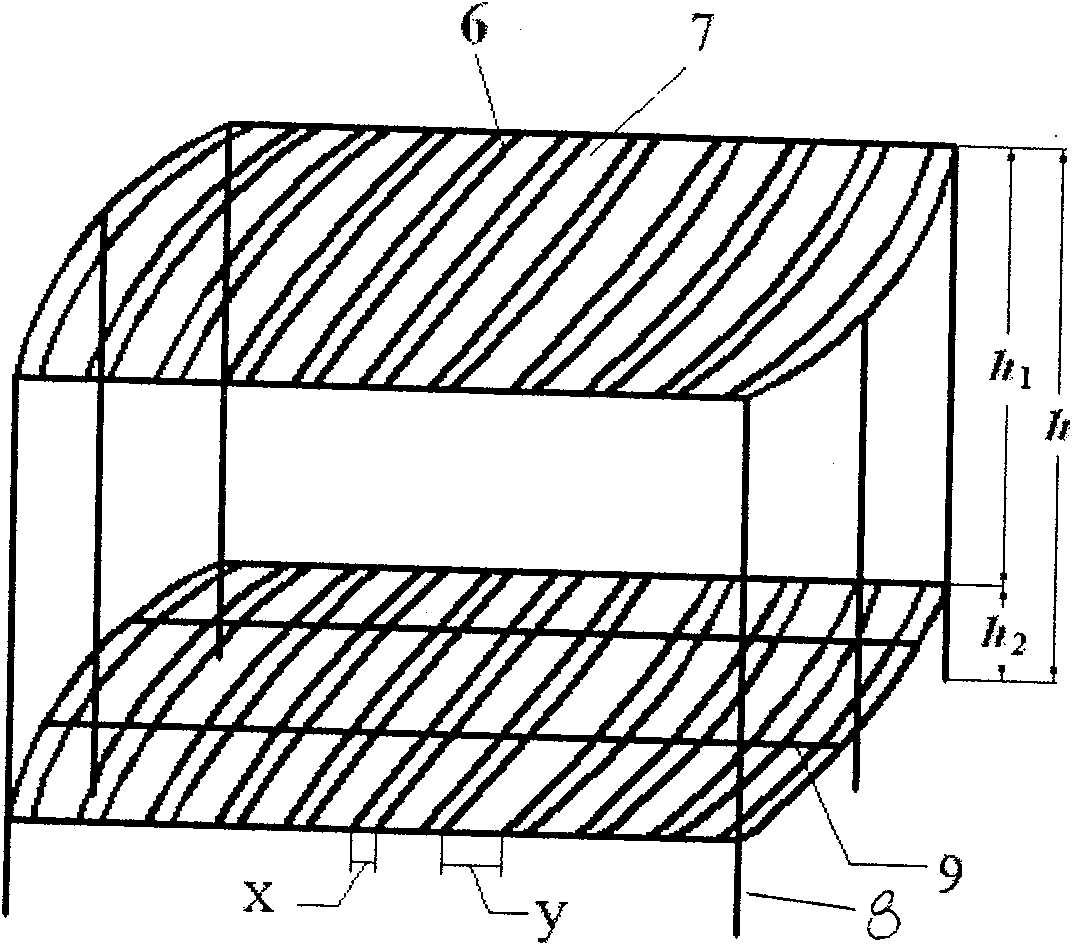

Diversion trench shaped catalyst orderly filling component in rectifying tower

InactiveCN101274146AGuaranteed to be fullGuarantee unimpededChemical/physical processesFractional distillationGas phasePlate column

The invention provides a guide channel-shaped catalyst regular packing component in a plate-typed reaction rectifying tower, which is provided with a supporting frame, and a fixed leg is arranged below the bottom surface of the supporting frame; the top surface and the bottom surface of the supporting frame are uniformly welded with a plurality groups of metal sheets in the flowing direction of liquid on the tower plate so as to form an catalyst inserted-sheet channel; the distance of two adjacent groups of metal sheets is a flowing passage of liquid phase and gas phase on the guide tower plate; the catalyst inserted-sheet is filled with catalyst and is formed by a plurality of square prisms which have the cross section of rhombus and are made of metal wire meshes, hexagonal prisms with the cross section of shuttle shape or elliptical cylinders with the cross section of ellipse, in which the inserted-sheet are connected with each other from head to end; metal pressing strips and washer strips clamp the wire mesh through screws from two sides of the metal wire meshes and hang and button on the metal sheet on the top surface and the bottom surface so as to fix the inserted-sheet and form the guide channel-shaped catalyst structured packing component in the plate-typed reaction rectifying tower. The component solves the problem of low catalyst efficiency in the reaction rectifying tower, improves the separation efficiency of the plate-typed tower, has simple structure, and is convenient for processing, manufacture, installation and maintenance.

Owner:NANJING UNIV

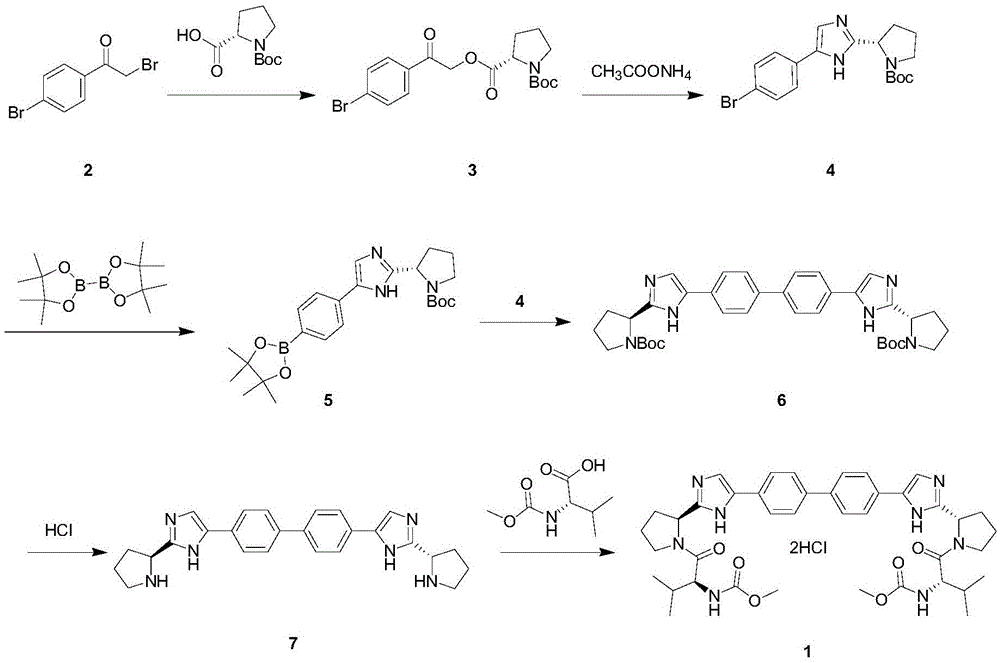

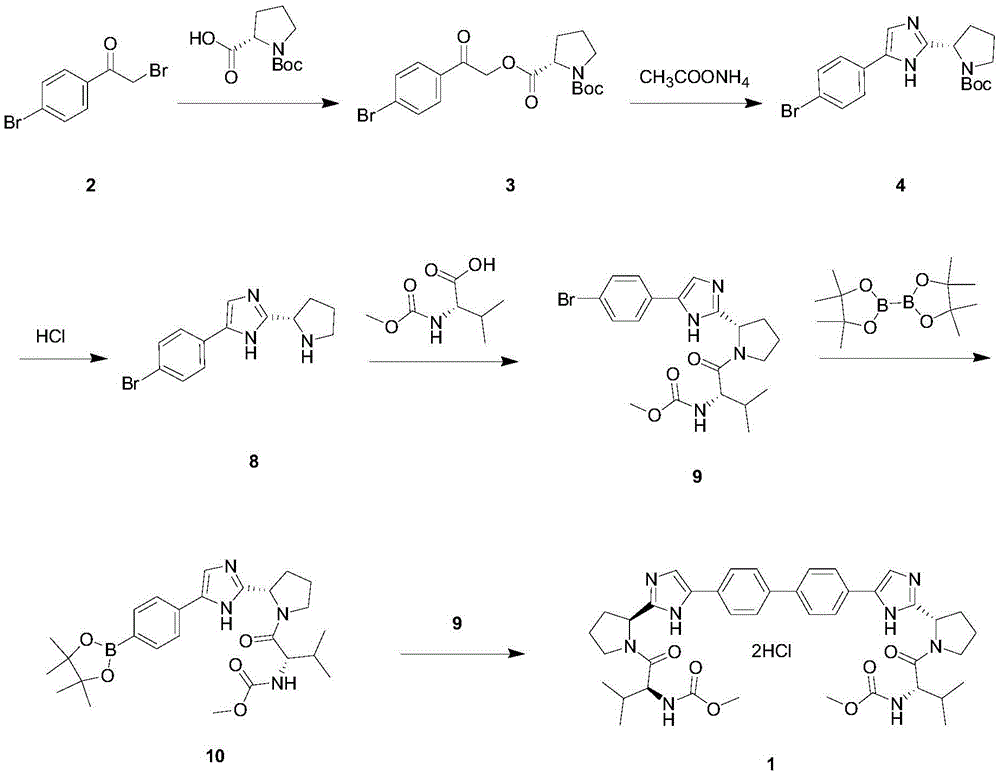

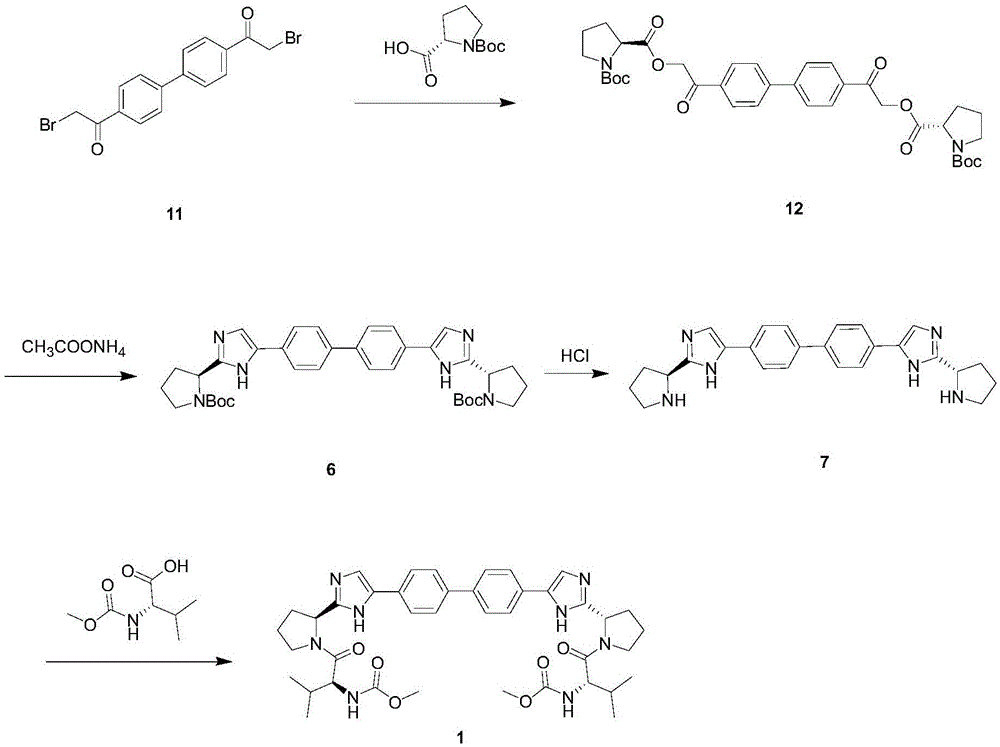

Novel preparation method for novel anti-hepatitis C drug-daklinza

The invention provides a novel preparation method for a novel anti-hepatitis C drug-daklinza. The method comprises the steps of performing condensation on 4,4'-bis(2-chloracetyl)biphenyl as a raw material and N-(methoxycarbonyl)-L-valyl-L-proline at first and then performing ring-closing on a condensation product and ammonium acetate to obtain daklinza. The method has the advantages of cheap raw materials, few reaction steps, relatively short synthetic cycle and wide applicability.

Owner:SUZHOU BUYUE PHARMA CO LTD

Corrosion-resistant treatment method for metal welding line

ActiveCN108262228AImprove corrosion resistanceAvoid preferential corrosionPretreated surfacesCoatingsCorrosion resistantElectrochemistry

The invention provides a corrosion-resistant treatment method for a metal welding line and relates to corrosion-resistant treatment for metal. According to the corrosion-resistant treatment method forthe metal welding line, a mussel adhesion protein / nanosized palladium composite membrane layer is constructed on the surface of a metal material after the pretreatment of the metal material to be treated, so that the corrosion resistance of the treated metal material is obviously improved; a mussel adhesion protein adopted is a natural environmentally-friendly material which can be extracted fromsea low-value mussels, the resource is rich, the cost is low and the industrialization prospects are good; the mussel adhesion protein adopted is good in anchoring strength and capable of complexingwith metal at the same time; the membrane layer adhesion is good and the prepared composite membrane layer has self repairing capacity at the same time; and the content of Pd adopted is very small andthe particle size of Pd in the prepared composite membrane layer is 100 nm in a diffuse distribution mode, so that the pitting corrosion resistance of the composite membrane layer is strengthened bythe electrochemical protection function of nanosized Pd and the bonding strength with the mussel adhesion protein is strengthened. The method is simple and practicable and strong in operability and has large-scale industrial application prospects.

Owner:XIAMEN UNIV +1

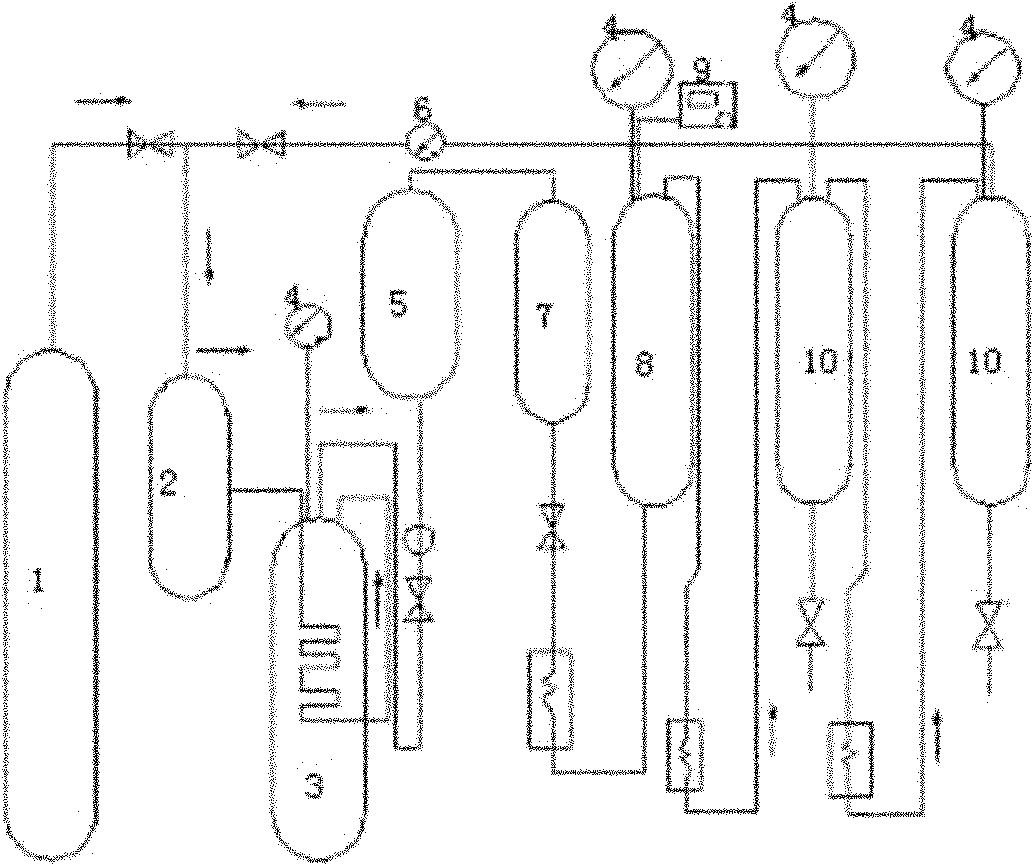

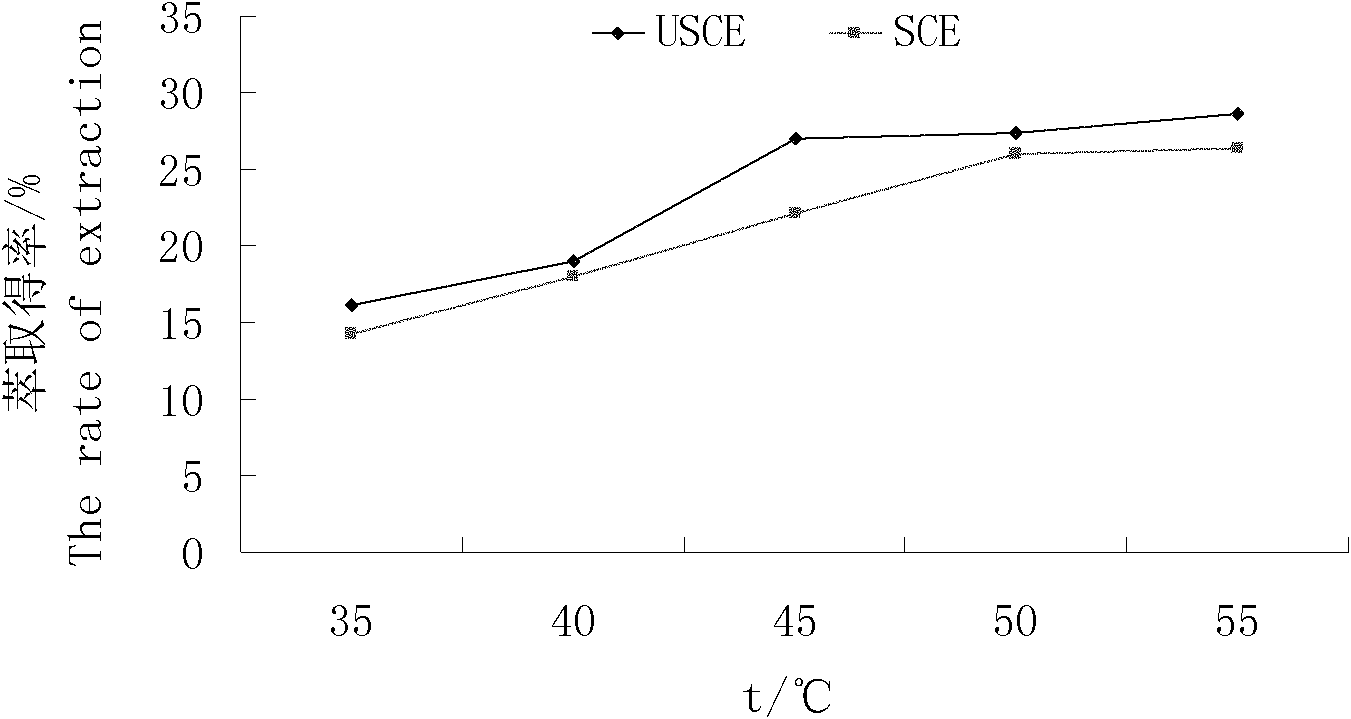

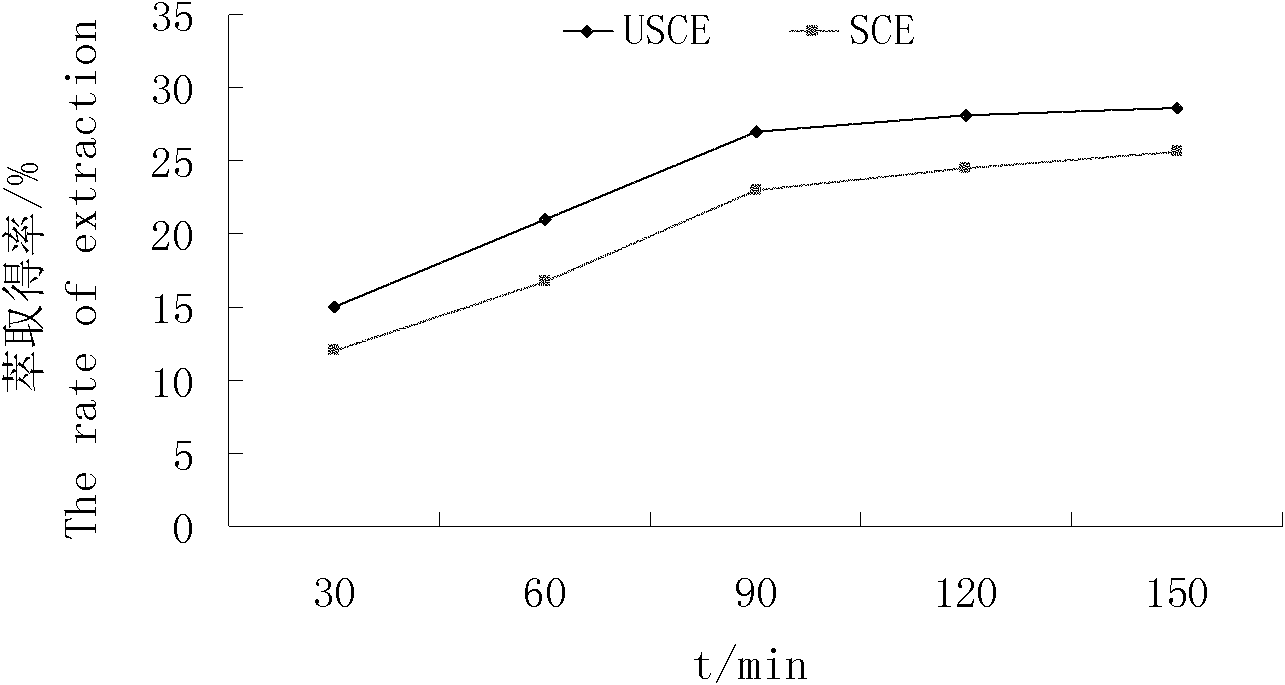

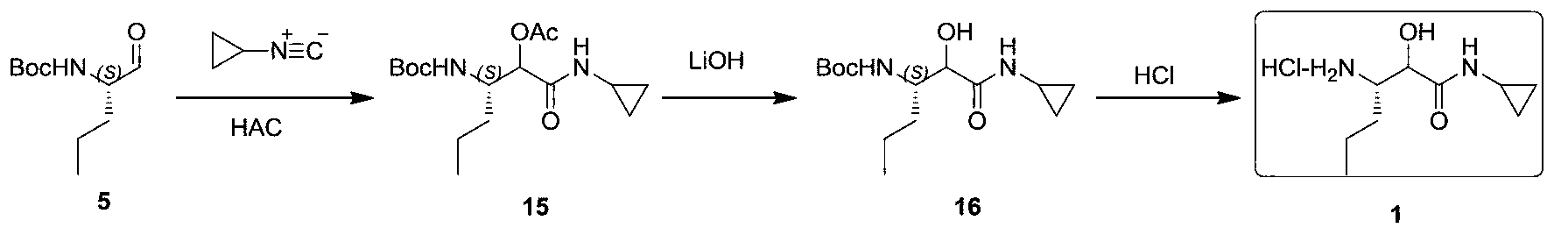

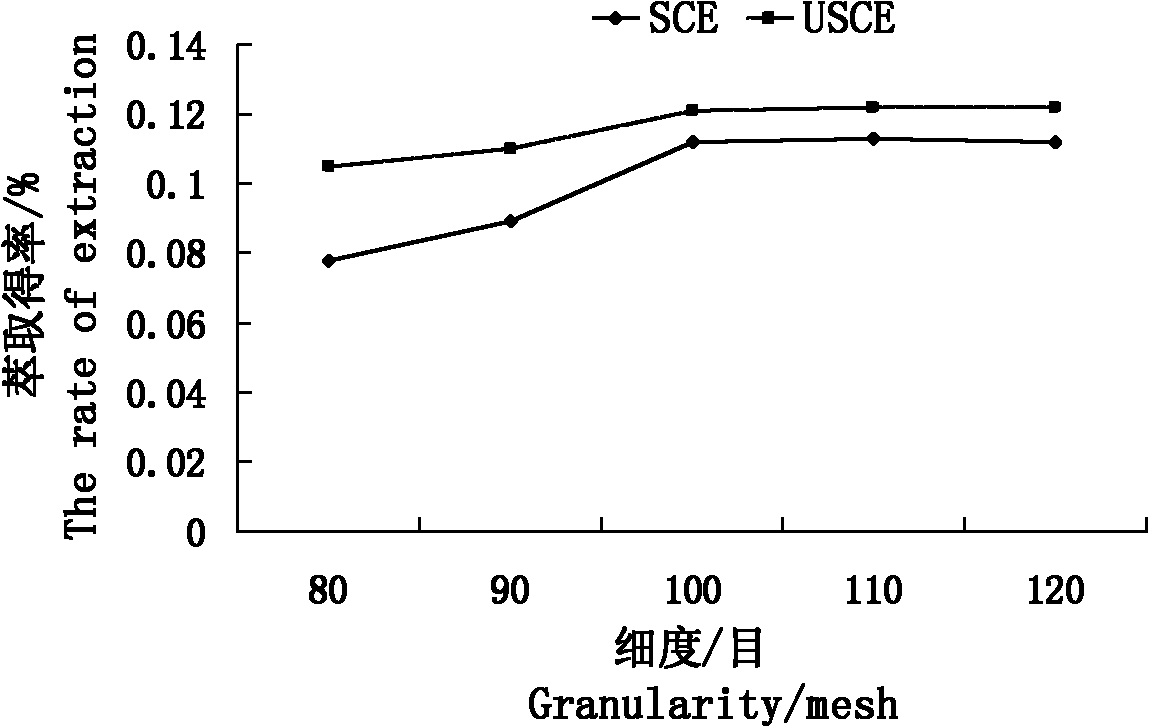

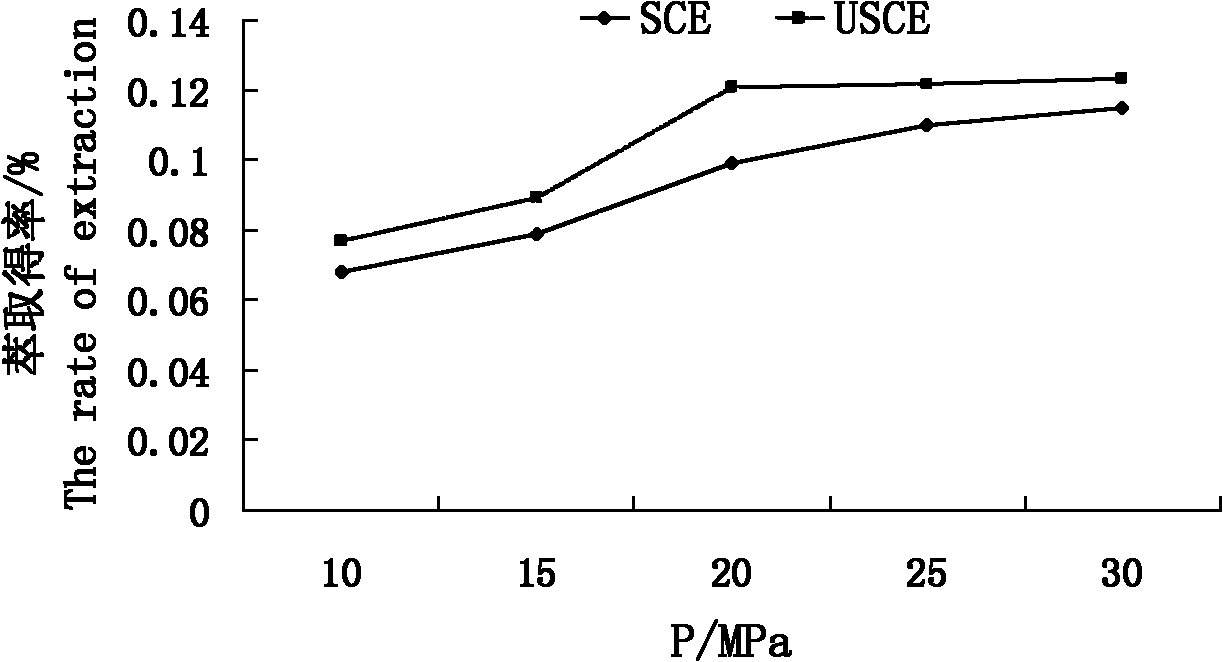

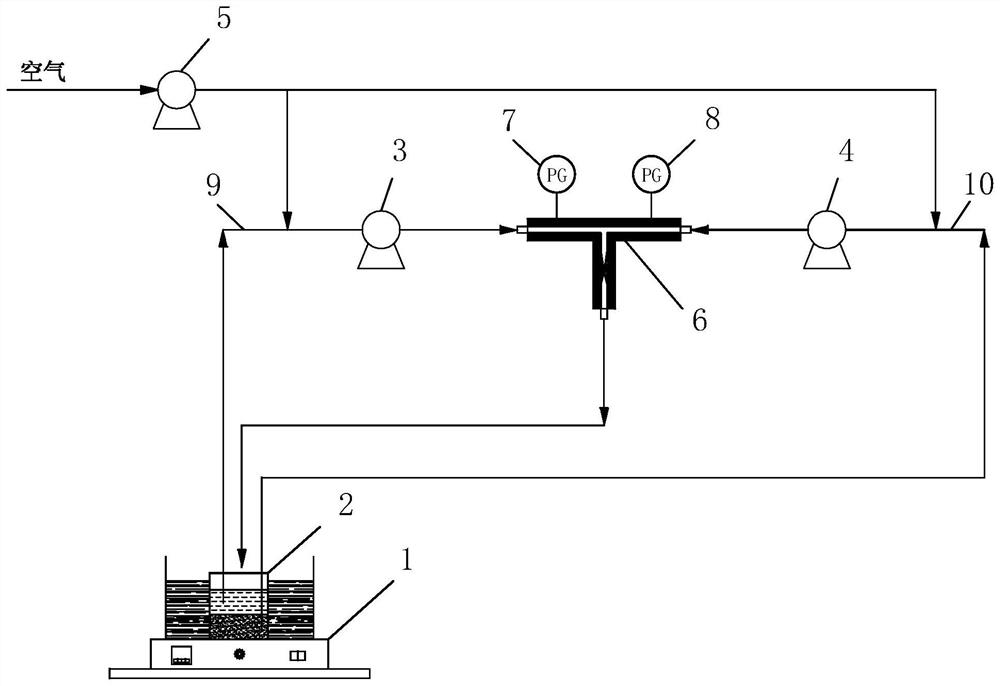

Preparation process and system for ultrasonic reinforced supercritical CO2 extraction of tussah pupa oil

InactiveCN101967426AReduce the temperatureShorten extraction timeFatty-oils/fats productionSupercritical fluid extractionChemistry

The invention relates to a preparation process for ultrasonic reinforced supercritical CO2 extraction of tussah pupa oil. The process comprises the following steps of: (1) pre-treating raw materials, namely sorting, cleaning, sterilizing and freeze-drying tussah pupas and crushing the tussah pupas into tussah pupa powder by adopting a high-speed crusher; (2) putting the tussah pupa powder obtained in the step (1) into an extraction kettle, opening a CO2 gas bottle when the temperature reaches 40 to 50 DEG C to blow gas, adjusting the flow when the extraction pressure reaches 18 to 25MPa, and extracting the tussah pupa oil for 60 to 120 minutes at constant temperature under constant pressure; (3) emitting ultrasonic wave to the supercritical CO2 fluid in the extraction kettle by adopting a built-in insertion ultrasonic reinforcing mode in the step (2) to reinforce the tussah pupa oil extraction process; and (4) collecting the tussah pupa oil at the outlet of a separation kettle. The preparation process can remarkably improve the production efficiency, save the production cost and reduce the production energy consumption, and has large-scale industrialized application prospect. The invention also relates to an ultrasonic reinforced supercritical CO2 extraction system for the tussah pupa oil. The system has the predominant advantages of reasonable design, convenience for control, high production efficiency, low energy consumption and the like.

Owner:王朝臣

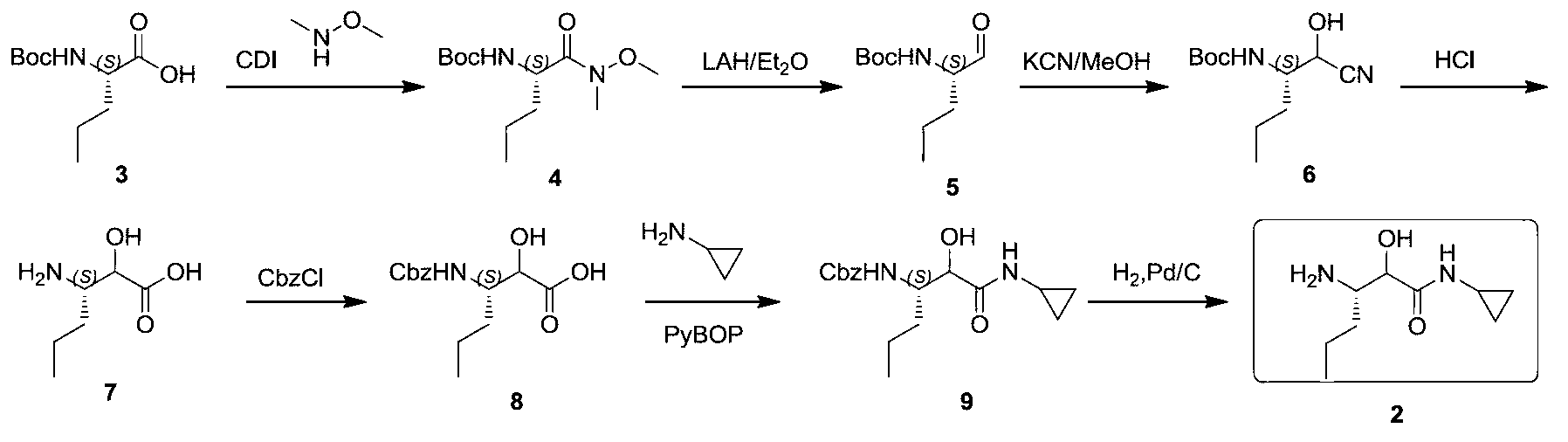

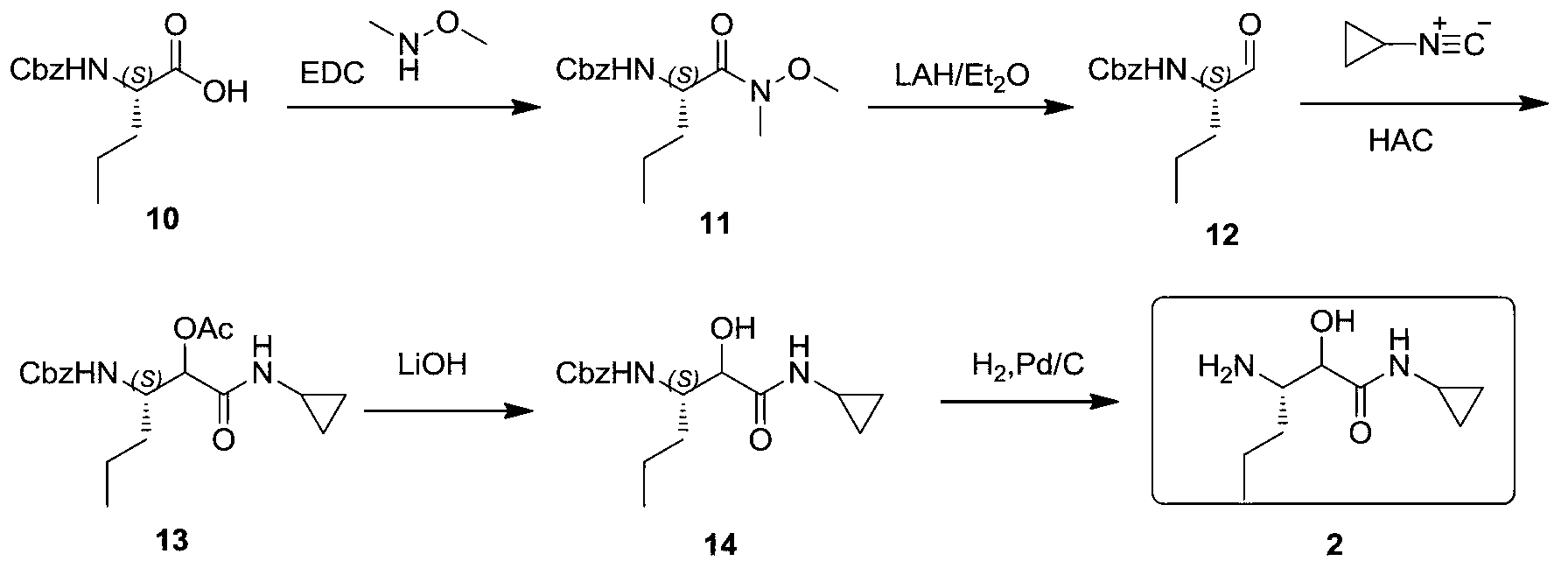

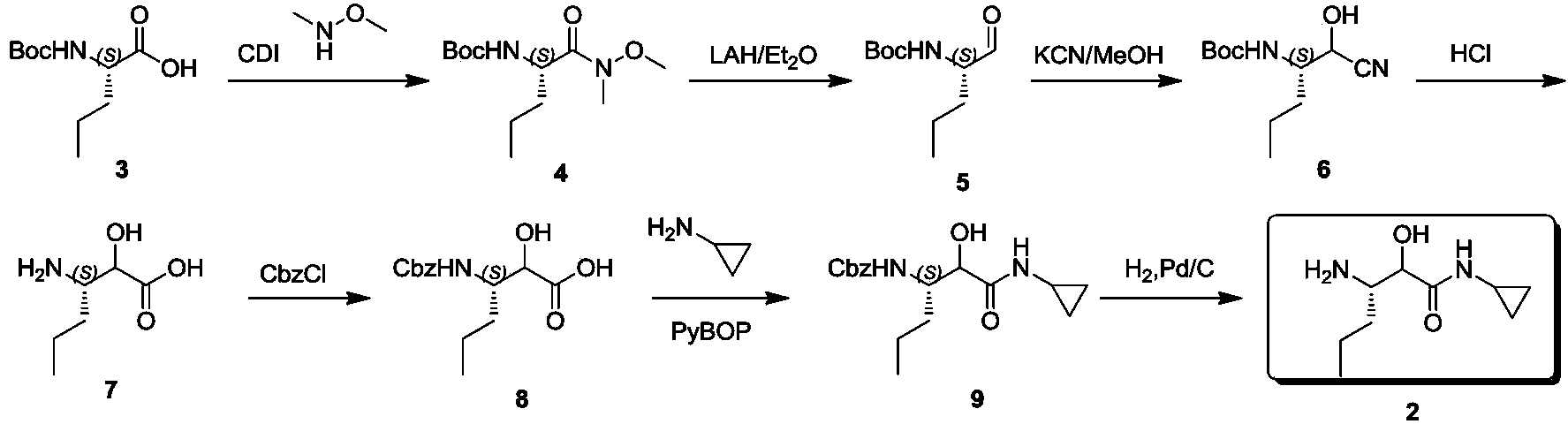

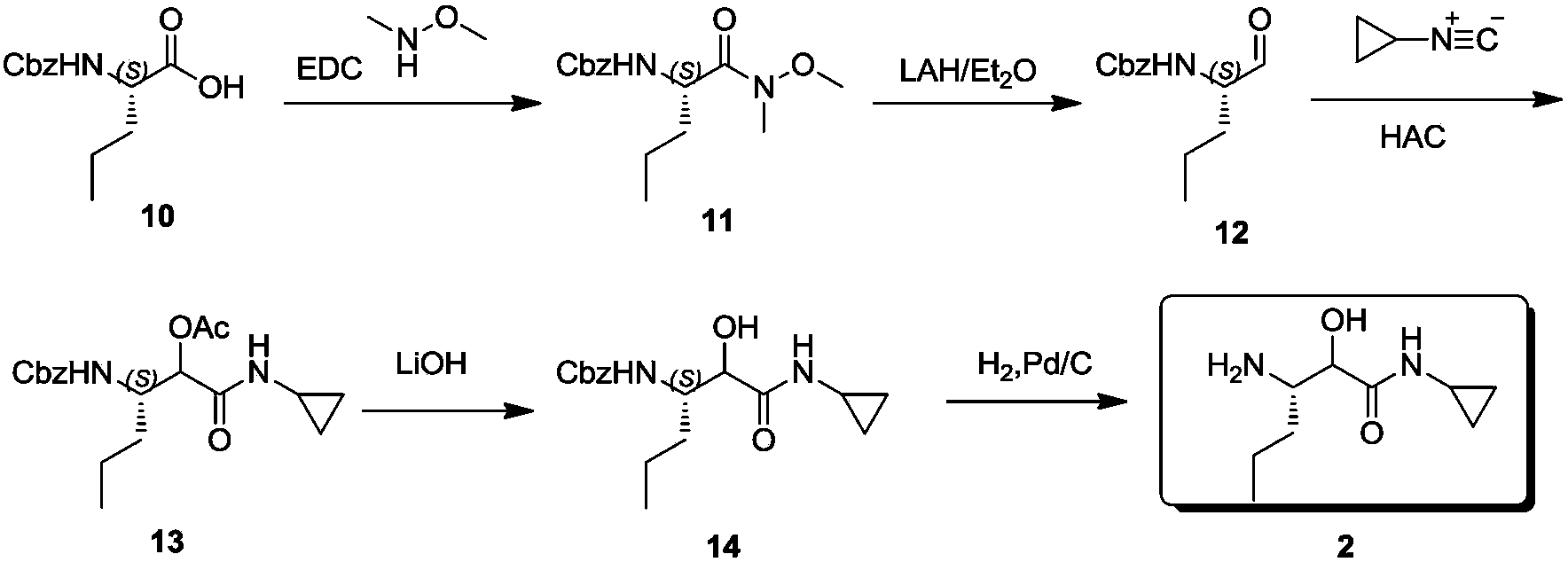

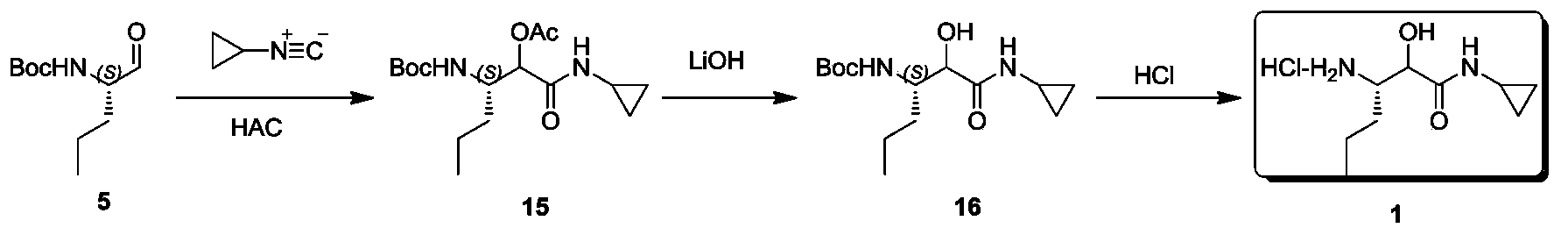

Synthetic method of (3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride

InactiveCN103288671AFew reaction stepsShort synthesis cycleOrganic compound preparationCarboxylic acid amides preparationN-benzyl-1-phenylethylamineTelaprevir

The invention provides a synthetic method of an intermediate (3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride of an anti-hepatitis C new drug Telaprevir. The method comprises the following steps: carrying out (S)-N-benzyl-1-phenylethylamine addition and camphorsulfonyloxaziridine oxidation of a cheap raw material t-butyl sorbate to obtain chiral amine, carrying out t-butyl deprotection, carrying out condensation with cyclopropylamine to obtain amide, and carrying out hydrogenation reduction benzyl-deprotection to form hydrochloride in order to obtain (3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride. The method has the advantages of less reaction steps, short synthetic period and strong applicability.

Owner:上海步越化工科技有限公司

Granular red mud absorbent and preparation method thereof

InactiveCN102600791AReach the role of recyclingHas large-scale industrial applicationOther chemical processesWater/sewage treatment by sorptionSorbentDry basis

The invention discloses a granular red mud absorbent used for processing a large quantity of low-concentration organic wastewater and heavy metal wastewater and a preparation method of the granular red mud absorbent, belonging to the technical field of environmental protection and water treatment. The prepared granular red mud absorbent comprises the following ingredients by weight: 60-70wt% of red mud dry basis, 2-10wt% of cement dry basis and 20-30wt% of water, the particle size range of the granular red mud absorbent is 0.05-5mm, the average pore size of the granular red mud absorbent is 22.13nm, the specific surface area of the granular red mud absorbent is 17.42-23.95m2 / g, and the total pore volume of the granular red mud absorbent is 0.1325ml / g. The method is implemented as follows: mixing red mud containing certain water and dry cement uniformly, mixing and granulating by adopting a granulator, and then maintaining in the wet environment to finally obtain the granular red mud absorbent. The produced granular red mud absorbent is low in cost and good in absorbing effect, is cheap and practical, has good desorption capability and can be applied to the treatment process of organic wastewater or heavy metal wastewater.

Owner:KUNMING UNIV OF SCI & TECH

Preparation process and system for ultrasonic reinforced supercritical CO2 extraction of tussah oil

InactiveCN101967424AImprove extraction yieldReduce the temperatureFatty-oils/fats productionGas cylinderFreeze-drying

The invention relates to a preparation process for ultrasonic reinforced supercritical CO2 extraction of tussah oil. The process comprises the following steps of: (1) pre-treating raw materials, namely sorting, cleaning, sterilizing and freeze-drying tussahs and crushing the tussahs into tussah powder by adopting a high-speed crusher; (2) putting the tussah powder obtained in the step (1) into an extraction kettle, opening a CO2 gas bottle when the temperature reaches 40 to 50 DEG C to blow gas, adjusting the flow when the extraction pressure reaches 18 to 25MPa, and extracting the tussah oil for 60 to 120 minutes at constant temperature under constant pressure; (3) emitting ultrasonic wave to the supercritical CO2 fluid in the extraction kettle by adopting a built-in insertion ultrasonic reinforcing mode in the step (2) to reinforce the tussah oil extraction process; and (4) collecting the tussah oil at the outlet of a separation kettle. The preparation process can remarkably improve the production efficiency, save the production cost and reduce the production energy consumption, and has large-scale industrialized application prospect. The invention also relates to an ultrasonic reinforced supercritical CO2 extraction system for the tussah oil. The system has the predominant advantages of reasonable design, convenience for control, high production efficiency, low energy consumption and the like.

Owner:王朝臣

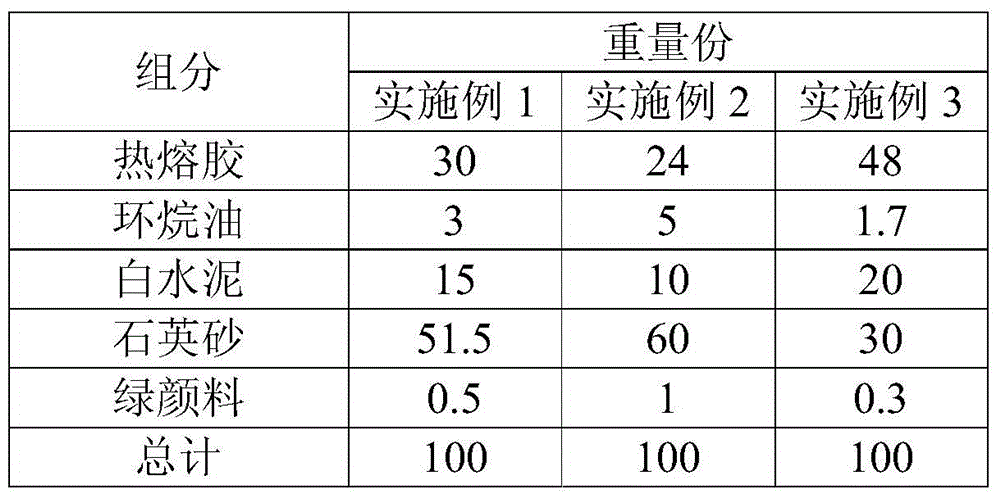

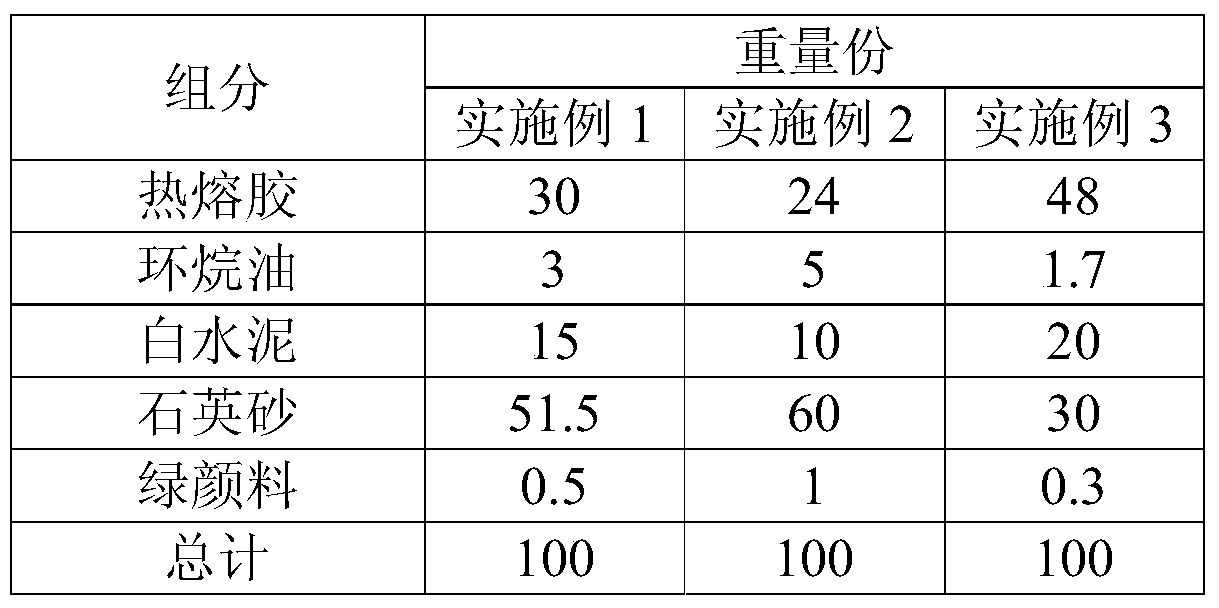

Polymer waterproof material

ActiveCN105669128AGood weather resistanceHigh peel strengthSynthetic resin layered productsPolymer scienceColloid

The invention provides a polymer waterproof material, which comprises polymer colloid. The polymer colloid is obtained by mixing the following ingredients (by weight): 20-48 parts of hot melt adhesive, 1.7-5 parts of naphthenic oil, 10-20 parts of white cement, 30-60 parts of quartz sand and 0.3-1 part of green pigment. The polymer waterproof material also comprises a fetal membrane and an isolating membrane. The polymer colloid is uniformly dip-coated between the fetal membrane and the isolating membrane. The polymer waterproof material has excellent weatherability, peel strength and waterproofness, and can provide a skin-type waterproof barrier for building materials. Environmentally-friendly non-asphaltic base raw materials are adopted, and the ingredients are not complex. The preparation technology is simple, and production cost is low. The polymer waterproof material has economical and environmental-protection characteristics and has a wide prospect for large-scale industrial application.

Owner:上海远盛建筑防水材料厂 +1

A polymer waterproof material

ActiveCN105669128BGood weather resistanceHigh peel strengthSynthetic resin layered productsPolymer scienceFoetal membranes

The invention provides a polymer waterproof material, which comprises polymer colloid. The polymer colloid is obtained by mixing the following ingredients (by weight): 20-48 parts of hot melt adhesive, 1.7-5 parts of naphthenic oil, 10-20 parts of white cement, 30-60 parts of quartz sand and 0.3-1 part of green pigment. The polymer waterproof material also comprises a fetal membrane and an isolating membrane. The polymer colloid is uniformly dip-coated between the fetal membrane and the isolating membrane. The polymer waterproof material has excellent weatherability, peel strength and waterproofness, and can provide a skin-type waterproof barrier for building materials. Environmentally-friendly non-asphaltic base raw materials are adopted, and the ingredients are not complex. The preparation technology is simple, and production cost is low. The polymer waterproof material has economical and environmental-protection characteristics and has a wide prospect for large-scale industrial application.

Owner:上海远盛建筑防水材料厂 +1

Waterproof material

InactiveCN109016715AGood weather resistanceThe components are not complicatedNon-macromolecular adhesive additivesRoof covering using flexible materialsWeather resistanceEnvironmental resistance

The invention discloses a waterproof material comprising a tire film, a separator film and a polymer colloid. The polymer colloid is uniformly applied between the tire film and the separator film, andis obtained by mixing the following components by weight: 20 to 48 parts of a hot melt adhesive; 1.7 to 5 parts of naphthenic oil; 10 to 20 parts of white cement; 30 to 60 parts of quartz sand; 0.3 to 1 part of a green pigment; 1 to 5 parts of nano silica and 1 to 3 parts of nano-alumina. The waterproof material has excellent weather resistance, peeling strength and waterproof performance, can build a skin-type waterproof barrier for building materials, adopts an environmentally-friendly non-asphalt-based raw material, and has uncomplicated components, simple preparation process, low production cost, economical and environmental protection characteristic, and broad prospects for large-scale industrial application.

Owner:安徽盟拓信息科技有限公司

A kind of synthetic method of (3s)-3-amino-n-cyclopropyl-2-hydroxyhexanamide hydrochloride

InactiveCN103288671BFew reaction stepsShort synthesis cycleOrganic compound preparationCarboxylic acid amides preparationN-benzyl-1-phenylethylamineHydroxyhexamide

The invention provides a synthetic method of an intermediate (3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride of an anti-hepatitis C new drug Telaprevir. The method comprises the following steps: carrying out (S)-N-benzyl-1-phenylethylamine addition and camphorsulfonyloxaziridine oxidation of a cheap raw material t-butyl sorbate to obtain chiral amine, carrying out t-butyl deprotection, carrying out condensation with cyclopropylamine to obtain amide, and carrying out hydrogenation reduction benzyl-deprotection to form hydrochloride in order to obtain (3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride. The method has the advantages of less reaction steps, short synthetic period and strong applicability.

Owner:上海步越化工科技有限公司

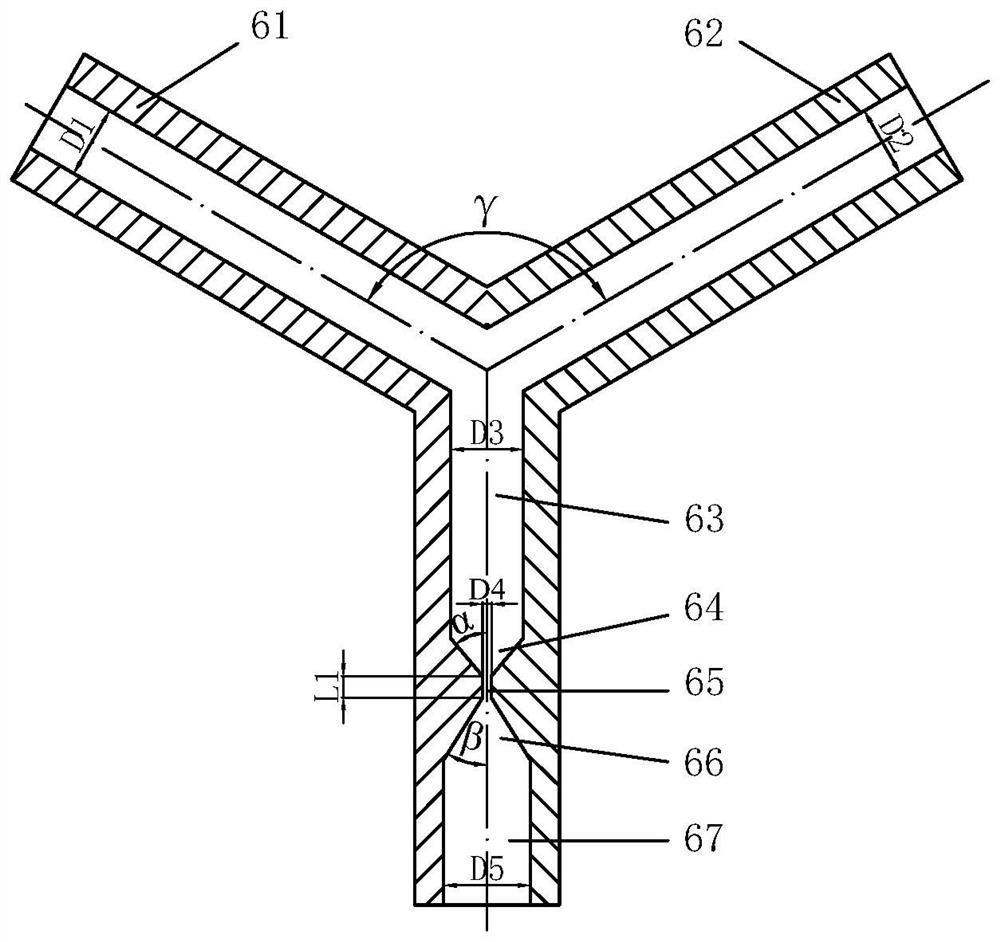

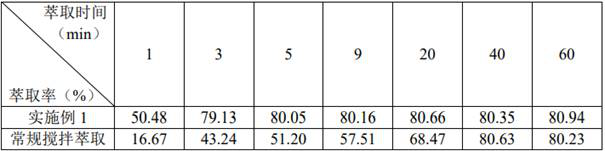

Method for intensively removing impurity ions in ammonium dihydrogen phosphate by utilizing hydrodynamic cavitation

PendingCN113896178AIncrease disturbanceHas large-scale industrial applicationPhosphatesLiquid solutions solvent extractionChemical physicsPhysical chemistry

The invention relates to a method for intensively removing impurity ions in ammonium dihydrogen phosphate by utilizing hydrodynamic cavitation, which comprises the following steps of respectively preheating an organic phase extractant solution and a water phase ammonium dihydrogen phosphate solution containing impurities to reaction temperatures, and respectively conveying organic phase and water phase feed liquid to impact type hydrodynamic cavitation extraction equipment through a circulating pump. The equipment comprises two inlet sections, an impact mixing section, a reducing section, a throat pipe section, an expanding section and a stabilizing section, gas is input into organic-phase and water-phase feed liquid through a gas adding pump, the pressure of a system is controlled by adjusting the rotating speed of a circulating pump, the gas-added feed liquid sequentially flows through the impact mixing section and the reducing section, the liquid is intensively mixed under the cavitation effect generated at the tail end of the throat pipe section and the expanding section, the mass transfer process occurs, and the fluid flows back to the storage tank through the stable section to be circularly extracted. According to the method, the extraction process can be completed within a short time, the extraction rate is greatly increased, and the method has the advantages of being easy to operate, low in energy consumption, easy for industrial large-scale production and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

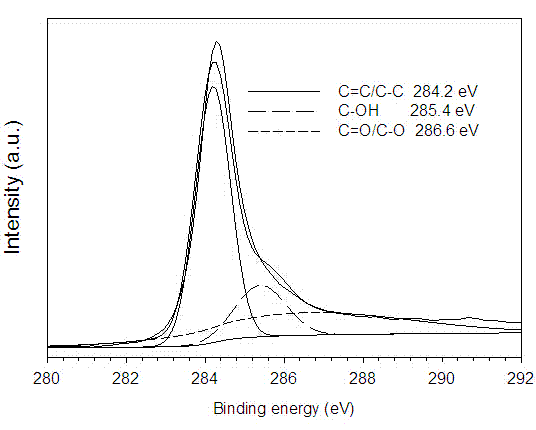

A kind of preparation method of graphene dispersion liquid

ActiveCN104772064BShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

The invention discloses a method for preparing a graphene dispersion liquid, which comprises the following steps: (1) adding graphene and a dispersant to a solvent and mixing them uniformly; (2) using a dispersion device to disperse the uniformly mixed liquid, adjusting The rotation speed of the high-shear dispersing head and the colloidal grinding disc is 100-14000 rpm, the rotation speed of the electric agitator is 10-2000 rpm, add a concentrated ultrasonic probe, the ultrasonic frequency is within 20-80 kHz, and adjust the dispersion temperature through the cooling system 0-20°C, after a dispersion time of 0.5-24 h, a graphene dispersion is obtained. The present invention adopts the combination of multiple dispersion methods, synergistic effect, saving dispersion time, improving production efficiency, low cost, simple operation, non-toxic and pollution-free, high dispersion stability, favorable for mass production, and broad prospects for large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

A kind of silk fibril cracking agent and its preparation and use method

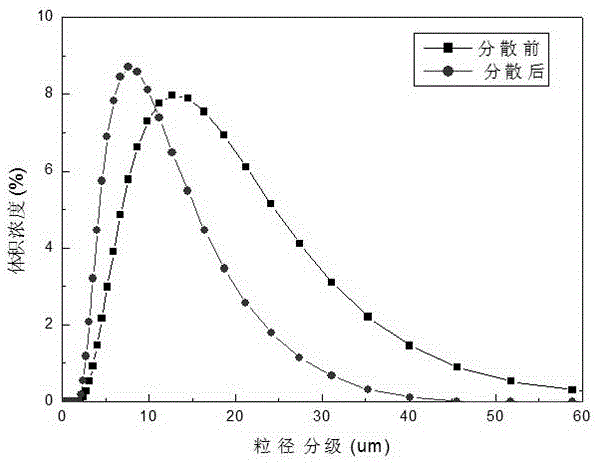

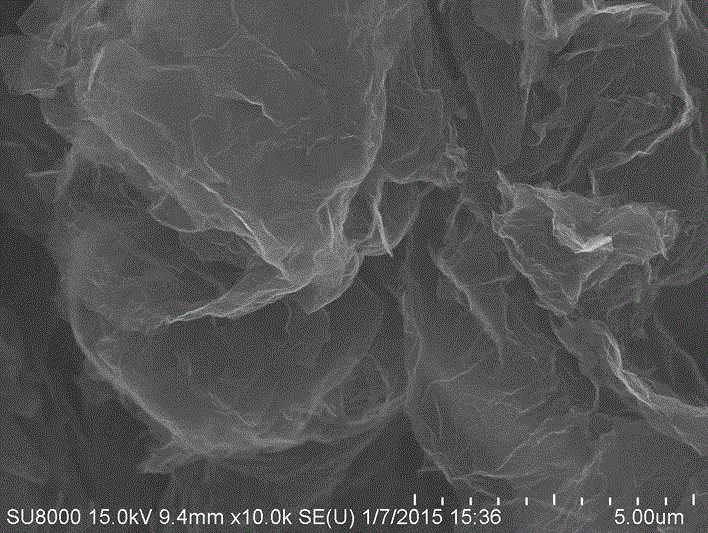

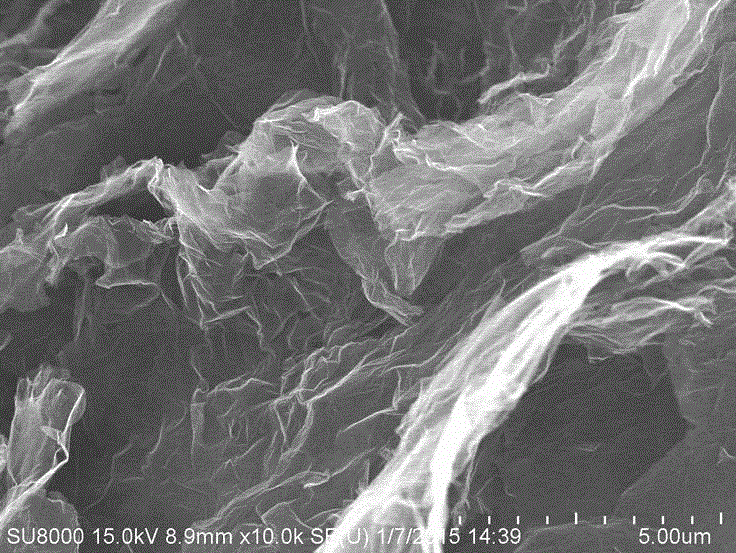

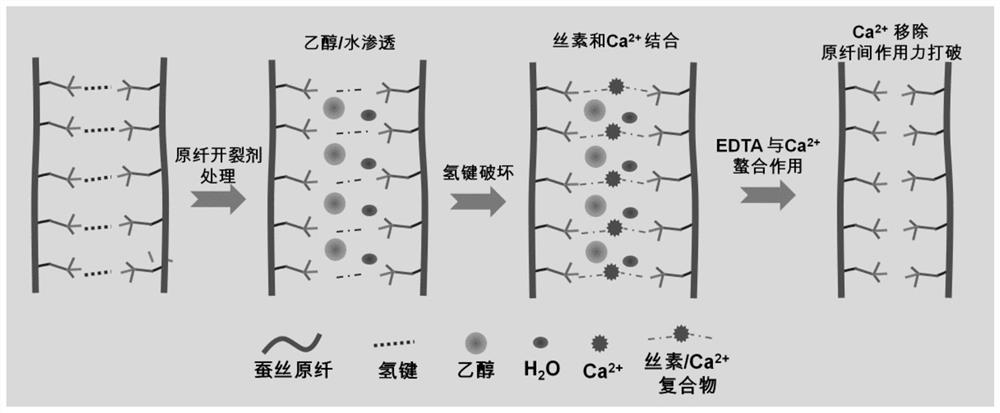

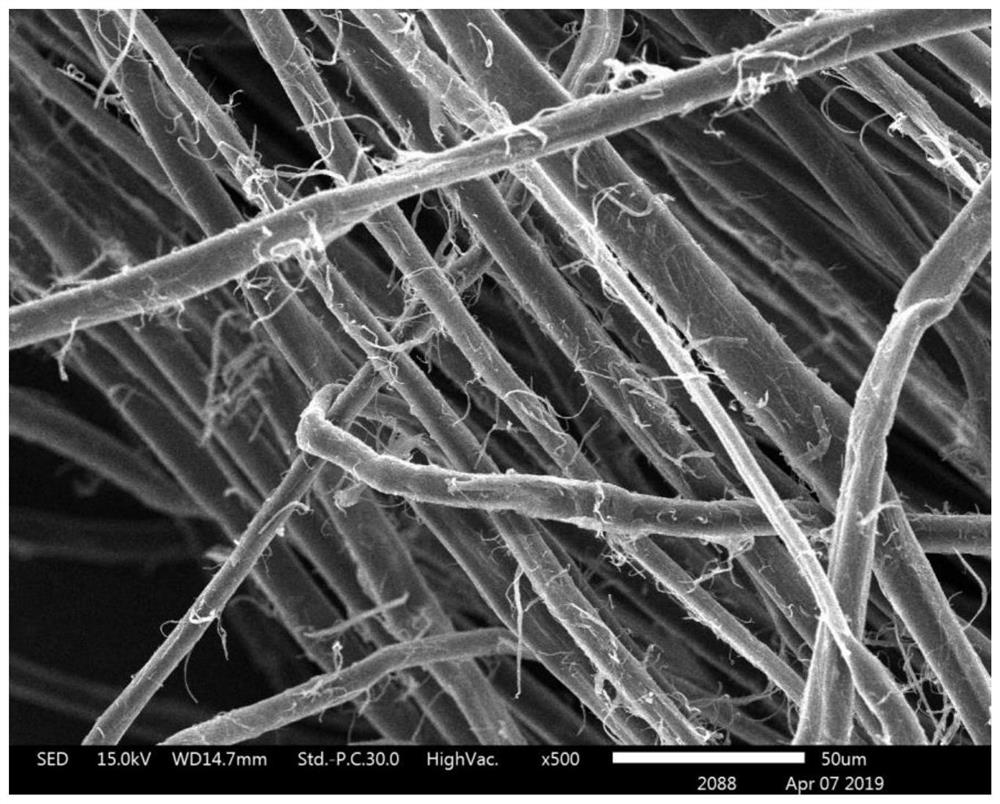

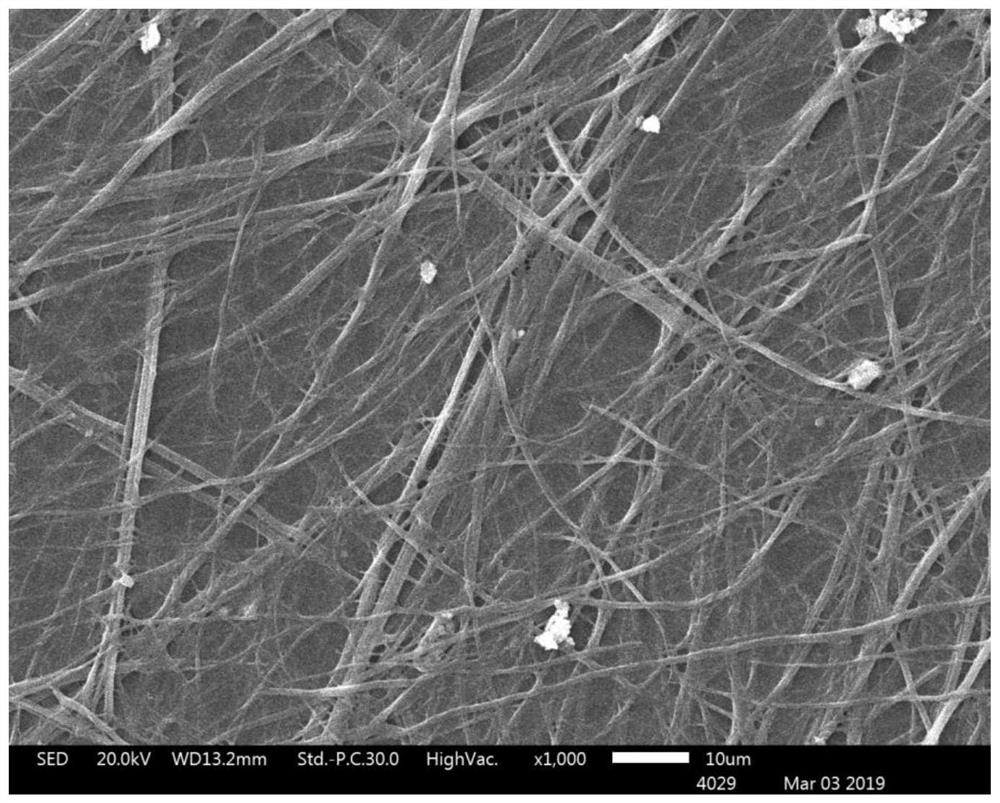

ActiveCN110318250BEasy to crackImprove separation efficiencyAnimal fibresPolymer sciencePolymer chemistry

The invention discloses a silk fibril cracking agent and its preparation and use methods. The silk fibril cracking agent is composed of two parts, Reagent No. 1 and Reagent No. 2, wherein Reagent No. 1 is a soluble calcium salt / alcohol / water ternary mixed solution, and Reagent No. 2 is Tris-EDTA solution. The degummed silk fibroin fibers are soaked in No. 1 reagent at 30-60 °C for 1 to 7 days, and then soaked in No. 2 reagent for 0.5 to 4 hours to obtain silk fibroin fibers with significantly weakened inter-fibril forces. . The silk fibril cracking agent provided by the invention can significantly improve the cracking and separation efficiency of the fibrils, and reduce the energy consumption and time required for the separation of silk micro-nano fibrils.

Owner:WUHAN TEXTILE UNIV

A kind of method utilizing self-vibration cavitation to prepare oligomeric chitosan

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

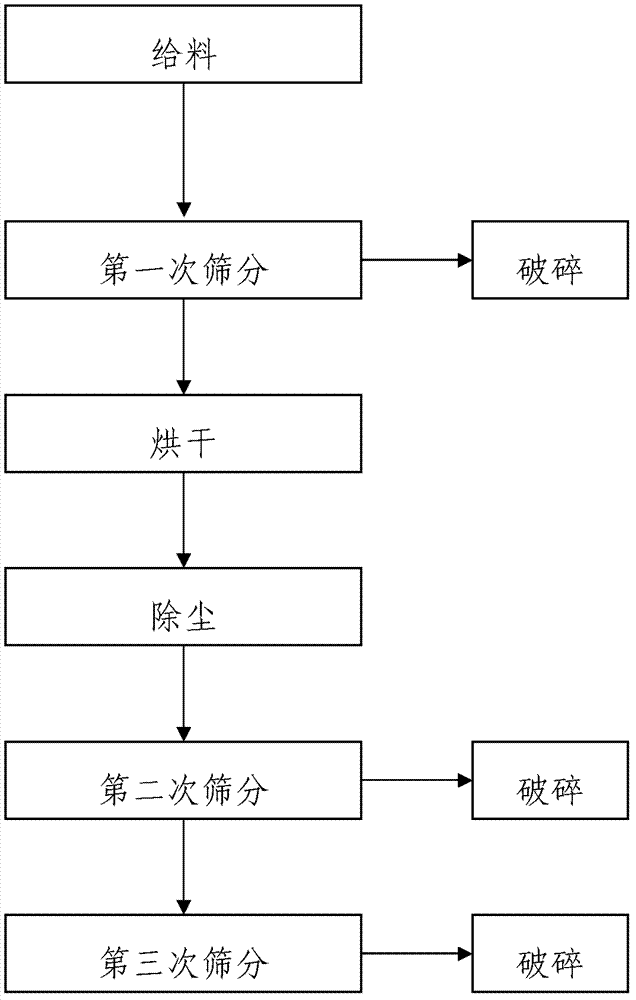

Method and system for pretreating lateritic nickel ore

ActiveCN102226233BHigh value-added utilizationImprove water removal effectProcess efficiency improvementPretreatment methodLaterite

The invention relates to a method and system for pretreating lateritic nickel ore. The invention is implemented by baking, screening and crushing lateritic nickel ore with high water content. By using the technical scheme provided by the invention, water can be effectively removed from lateritic nickel ore with high water content and viscosity, and lump ore and fine ore are recycled respectively,thereby providing insurance for efficient utilization of lateritic nickel ore; and besides, the technological process and equipment are simple and accessible, so that the cheap lateritic nickel ore has large-scale industrial application prospects.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Acyltransferase for catalytic synthesis of simvastatin and mutant thereof

ActiveCN107267479AImprove thermal stabilityGood storage stabilityTransferasesFermentationWild typeAmino acid

The invention provides acyltransferase for catalytic synthesis of simvastatin and a preparation method thereof. The acyltransferase has an amino acid sequence as shown in SEQ ID No. 2, and the site 161, site 163, site 180 and site 235 of the amino acid sequence undergo mutation so as to obtain a mutant. The enzyme activity of the novel acyltransferase in the invention is 12 times the enzyme activity of a wild enzyme; and the acyltransferase provided by the invention has the characteristics of low cost, short conversion time, simple operation, etc. and has good large-scale industrial application prospects.

Owner:杭州泓友医药科技有限公司

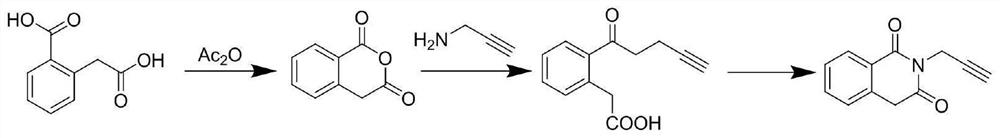

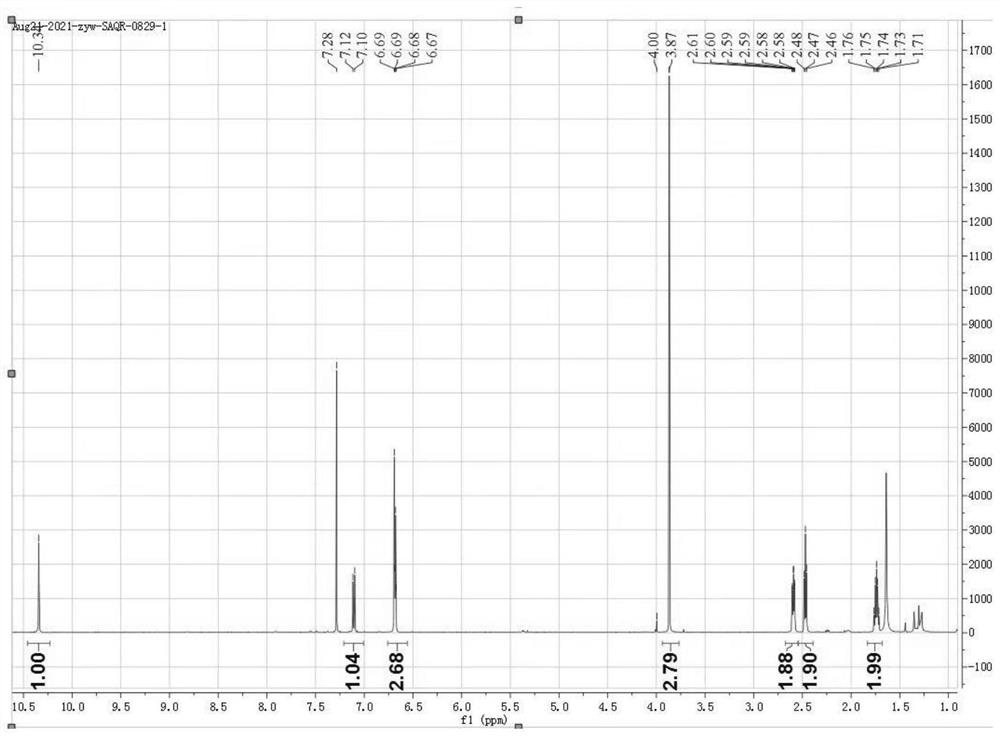

Preparation method of N-propyl-2-alkynyl phthalimide

The invention belongs to the technical field of organic synthesis, and particularly relates to a preparation method of N-propyl-2-alkynyl phthalimide. The preparation method of the N-propyl-2-alkynyl phthalimide provided by the invention comprises the following steps: mixing 2-formic acid phenylacetic acid with acetic anhydride, and carrying out a dehydration reaction to obtain phthalic anhydride; mixing the phthalic anhydride, propargylamine and a phthalic anhydride good solvent, and carrying out ammonolysis reaction, so as to obtain N-propyl-2-alkynyl benzamide-2-acetic acid; and mixing the N-propyl-2-alkynyl benzamide-2-acetic acid with a good solvent of the N-propyl-2-alkynyl benzamide-2-acetic acid, and carrying out a ring formation reaction, so as to obtain the N-propyl-2-alkynyl phthalimide. The preparation method of the N-propyl-2-alkynyl phthalimide, provided by the invention, has the advantages of high product yield, high purity, simple steps and low production cost, and has a prospect of large-scale industrial application.

Owner:BAYECAO HEALTH IND RES INST (XIAMEN) CO LTD

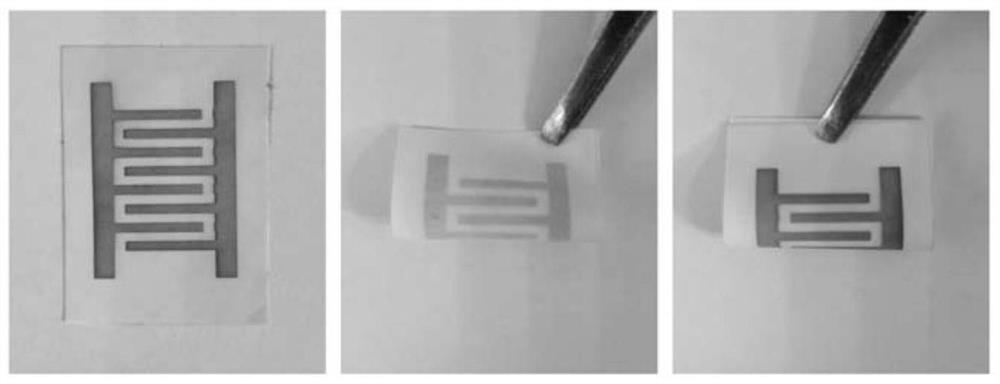

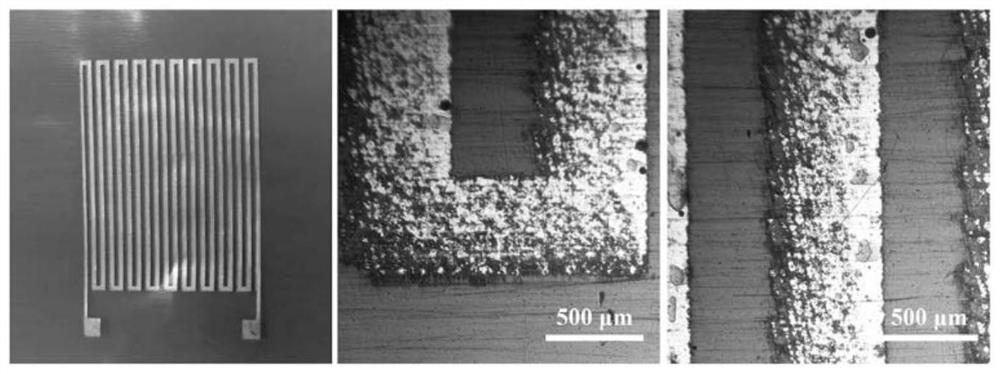

Flexible bendable metal pattern based on laser technology and preparation method and application thereof

PendingCN114786342AGood production flexibilityEasy to operateDielectric materialsFlexible printed circuitsLaser technologyScreen printing

The invention provides a flexible bendable metal pattern based on a laser technology and a preparation method and application thereof, and belongs to the field of flexible circuits. According to the preparation method, the conductive metal pattern or circuit is prepared on the flexible polymer film coated with the laser sensitizer through laser activation selective metallization. The prepared flexible metal pattern has ultrahigh bending resistance, after 10000 times of bending with the bending radius of 1 mm, the resistance value of the flexible metal pattern is kept basically unchanged, and connection of a metal circuit can be kept under the condition of complete folding. The preparation method does not need a mask or expensive equipment, and compared with a traditional etching method, a silk-screen printing process and an ink-jet printing process, the method is good in production flexibility, easy to operate, controllable in cost and good in universality and has a large-scale industrial application prospect.

Owner:SICHUAN UNIV

Preparation method of oligochitosan

The invention relates to a preparation method of oligochitosan. The oligochitosan is prepared through degradation of chitosan under hydraulic cavitation of chitosan solution. The preparation method comprises the following steps: dissolving the chitosan, carrying out hydraulic cavitation and degradation, adding alkali solution into the chitosan solution after degradation to adjust the pH, washing precipitates, carrying out vacuum drying and the like. The process of hydraulic cavitation and degradation comprises the following steps: placing the chitosan solution into a storage tank, maintaininga constant temperature through a circulating water tank, delivering the chitosan solution to a cavitation device for cavitation and degradation through a pump, adjusting the pressure of the upstream inlet with a valve V1, a valve V2, a valve V3 and a valve V4, restoring the pressure and flow of the downstream, monitoring the pressure and flow with a pressure gauge and a flow meter, making the solution after cavitation and degradation flow back to the storage tank, controlling the temperature to be 25-80 DEG C through the circulating water tank, and carrying out the circulating process in the hydraulic cavitation device for 0.5-20 hour(s) until the oligochitosan satisfies the requirements for the relative molecular mass. The method has the advantages of simple and convenient operation, lowenergy consumption, high efficiency and the like.

Owner:WUHAN NORJAN BIOLOGICAL TECH

Diversion trench shaped catalyst orderly filling component in rectifying tower

InactiveCN100579618CGuaranteed to be fullGuarantee unimpededChemical/physical processesFractional distillationPtru catalystFluid phase

The invention provides a guide channel-shaped catalyst regular packing component in a plate-typed reaction rectifying tower, which is provided with a supporting frame, and a fixed leg is arranged below the bottom surface of the supporting frame; the top surface and the bottom surface of the supporting frame are uniformly welded with a plurality groups of metal sheets in the flowing direction of liquid on the tower plate so as to form an catalyst inserted-sheet channel; the distance of two adjacent groups of metal sheets is a flowing passage of liquid phase and gas phase on the guide tower plate; the catalyst inserted-sheet is filled with catalyst and is formed by a plurality of square prisms which have the cross section of rhombus and are made of metal wire meshes, hexagonal prisms with the cross section of shuttle shape or elliptical cylinders with the cross section of ellipse, in which the inserted-sheet are connected with each other from head to end; metal pressing strips and washer strips clamp the wire mesh through screws from two sides of the metal wire meshes and hang and button on the metal sheet on the top surface and the bottom surface so as to fix the inserted-sheet and form the guide channel-shaped catalyst structured packing component in the plate-typed reaction rectifying tower. The component solves the problem of low catalyst efficiency in the reaction rectifying tower, improves the separation efficiency of the plate-typed tower, has simple structure, and is convenient for processing, manufacture, installation and maintenance.

Owner:NANJING UNIV

Method capable of preparing few-layer graphene powder in batches

The invention particularly relates to a method capable of preparing few-layer graphene powder in batches. By using various electrolytes as a flocculent floating agent of a graphene colloidal solution, the graphene quickly floats on the upper side of the solution to prepare the graphene powder. According to the method provided by the invention, a diluted graphene oxide solution is reduced by virtue of hydrazine hydrate to form the graphene colloidal solution, so that the reductive graphene is prevented from being agglomerated in a large quantity. By using the flocculent floating agents of electrolyte solutions of acids, bases and alkalis, the graphene is quick to wash, so that the method is simple to operate and beneficial for quantity production and has a wide prospect of large-scaled industrialized application. The diluted solution is used in the method, so that the whole reaction process is less in influence on the environment. Moreover, the waste liquid contains few ions, so that the treatment cost is low.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com