Polymer waterproof material

A technology of polymer waterproofing and polymer colloid, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of low peel strength and insufficient waterproof performance, and achieve uncomplicated and excellent components. The effect of weather resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 , Preparation of polymer colloid

[0033] Put 30 parts of hot melt adhesive and 3 parts of naphthenic oil into the oxidation kettle according to the weight ratio, heat to 130 ° C, after the hot melt adhesive and naphthenic oil melt, stir evenly, then put 15 parts of white cement and 51.5 parts of quartz sand and 0.5 part of green pigment, the system was heated to 140° C., and stirred evenly to prepare polymer colloid.

Embodiment 2

[0034] Example 2 , Preparation of polymer colloid

[0035] Put 20 parts of hot melt adhesive and 6 parts of naphthenic oil into the oxidation kettle according to the weight ratio, heat to 110°C, after the hot melt adhesive and naphthenic oil melt, stir evenly, then add 11 parts of white cement and 62 parts of quartz sand and 1 part of green pigment, heat the system to 120°C, stir evenly, and prepare polymer colloid.

Embodiment 3

[0036] Example 3 , Preparation of polymer colloid

[0037] Put 48 parts of hot melt adhesive and 1.7 parts of naphthenic oil into the oxidation kettle according to the weight ratio, heat to 150 ° C, after the hot melt adhesive and naphthenic oil melt, stir evenly, then put 20 parts of white cement and 30 parts of quartz sand and 0.3 parts of green pigment, the system was heated to 160° C., stirred evenly, and the polymer colloid was prepared.

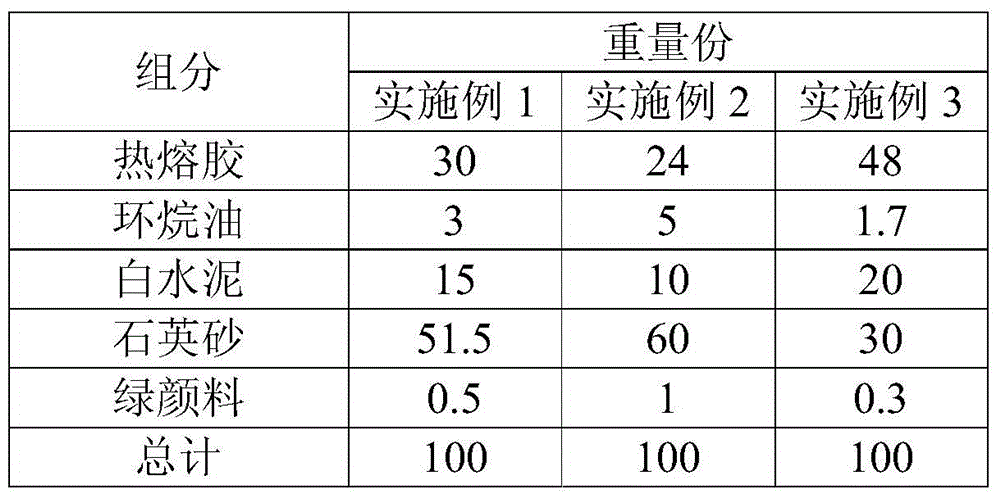

[0038] The specific formula of embodiment 1-3 polymer colloid is as shown in table 1:

[0039] Table 1 polymer colloid formula

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com