Metal-solution reduction method for preparing graphene

A technology of graphene and reduction method, applied in the field of new energy material preparation, can solve the problems of high cost, pollution, low graphene quality, etc., and achieve the effects of low processing cost, simple operation, and favorable mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

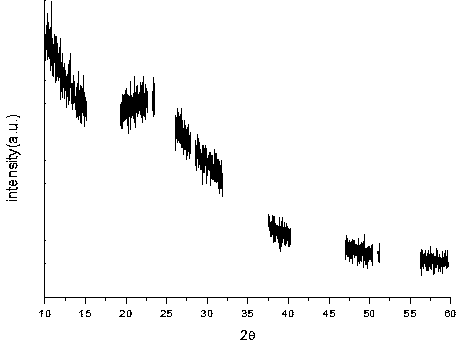

Image

Examples

Embodiment 1

[0021] The present embodiment graphene preparation process is:

[0022] (1) Graphene oxide: Graphene oxide is prepared by the phosphoric acid sealing method independently developed by our company: first, 200g of natural graphite and 5L mixed acid composed of 4.5L concentrated sulfuric acid and 0.5L concentrated phosphoric acid are mixed in the reactor and controlled electronically. Stir evenly with a magnetic stirrer, and slowly add 500g of potassium permanganate at a temperature lower than 20°C; after that, seal the reactor and raise the temperature to 80°C to react for 2 hours, take the product out from the lower end of the reactor, dilute it into a 40L solution, and add 0.6L hydrogen peroxide to obtain a bright yellow graphite oxide solution; then, alternately centrifuge washing with acid (hydrochloric acid) and water until the solution pH=5-6 to remove impurity ions; finally, ultrasonically disperse graphite oxide to prepare a certain concentration of graphene oxide soluti...

Embodiment 2

[0025] The present embodiment graphene preparation process is:

[0026] (1) Graphene oxide: Graphene oxide is prepared by the phosphoric acid sealing method independently developed by our company: first, 200g of natural graphite and 5L mixed acid composed of 4.5L concentrated sulfuric acid and 0.5L concentrated phosphoric acid are mixed in the reactor and controlled electronically. Stir evenly with a magnetic stirrer, and slowly add 500g of potassium permanganate at a temperature lower than 20°C; after that, seal the reactor and raise the temperature to 75°C for 4 hours, take the product out of the lower end of the reactor, dilute it into a 40L solution, and add 0.6L hydrogen peroxide to obtain a bright yellow graphite oxide solution; then, alternately centrifuge washing with acid (sulfuric acid) and water until the solution pH=5-6 to remove impurity ions; finally, ultrasonically disperse graphite oxide to prepare a certain concentration of graphene oxide solution.

[0027] (...

Embodiment 3

[0029] The present embodiment graphene preparation process is:

[0030] (1) Graphene oxide: Graphene oxide is prepared by the phosphoric acid sealing method independently developed by our company: first, 200g of natural graphite and 5L mixed acid composed of 4.5L concentrated sulfuric acid and 0.5L concentrated phosphoric acid are mixed in the reactor and controlled electronically. Stir evenly with a magnetic stirrer, and slowly add 500g of potassium permanganate at a temperature lower than 20°C; after that, seal the reactor and raise the temperature to 85°C to react for 1 hour, take out the product from the lower end of the reactor, dilute it into a 40L solution, and add 0.6L hydrogen peroxide to obtain a bright yellow graphite oxide solution; then, alternately centrifuge washing with acid and water until the pH of the solution is 5-6 to remove impurity ions; finally, ultrasonically disperse graphite oxide to prepare a graphene oxide solution with a certain concentration.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com