Diversion trench shaped catalyst orderly filling component in rectifying tower

A technology of reactive distillation column and catalyst, which is applied in fractionation, distillation separation, chemical instruments and methods, etc., can solve the problems of difficult diffusion of reaction products, influence on liquid flow, mechanical damage of catalyst, etc., so as to improve catalytic efficiency and mass transfer efficiency. , easy to manufacture, improve the effect of serious stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

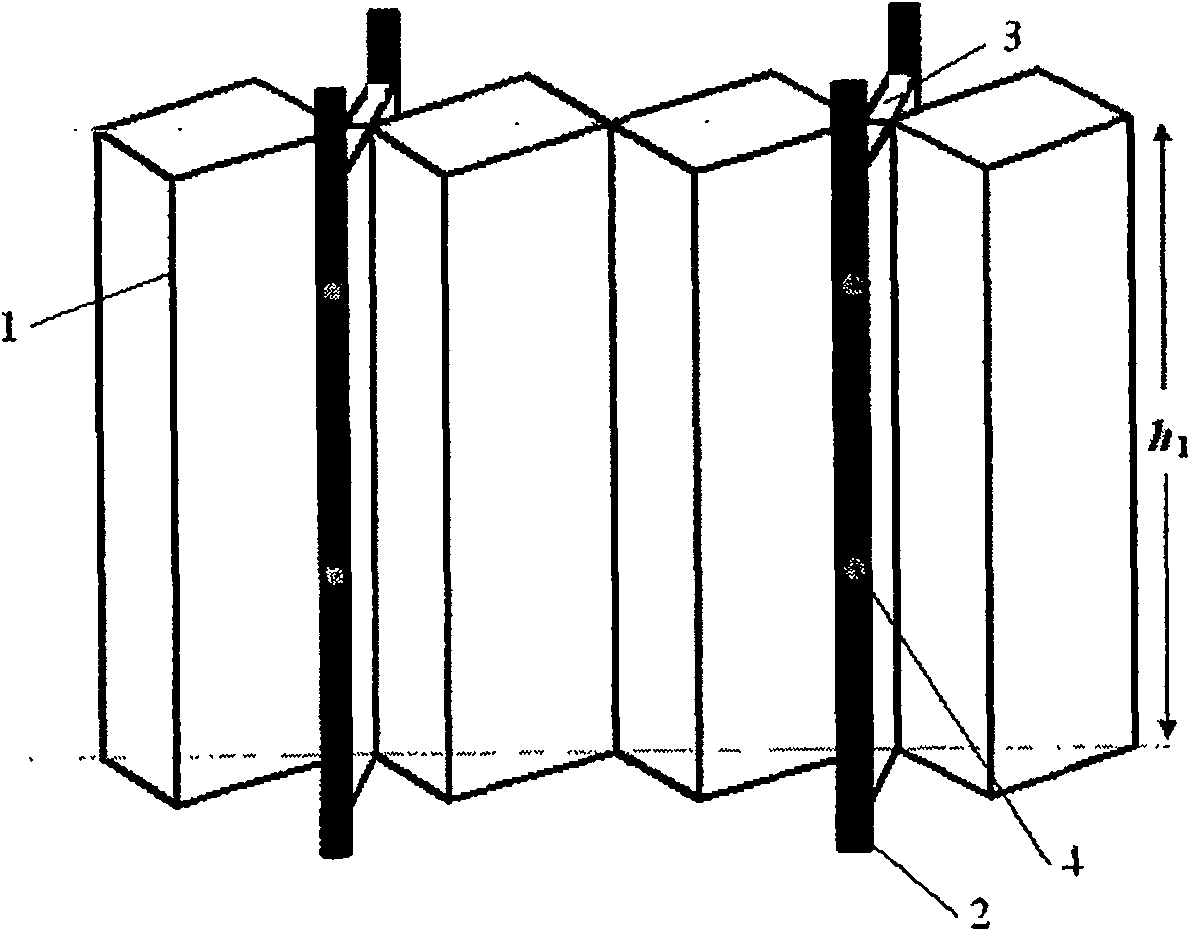

[0024] Example 1. An example of a diversion tank-shaped catalyst structured packing assembly in a plate-type reactive distillation column

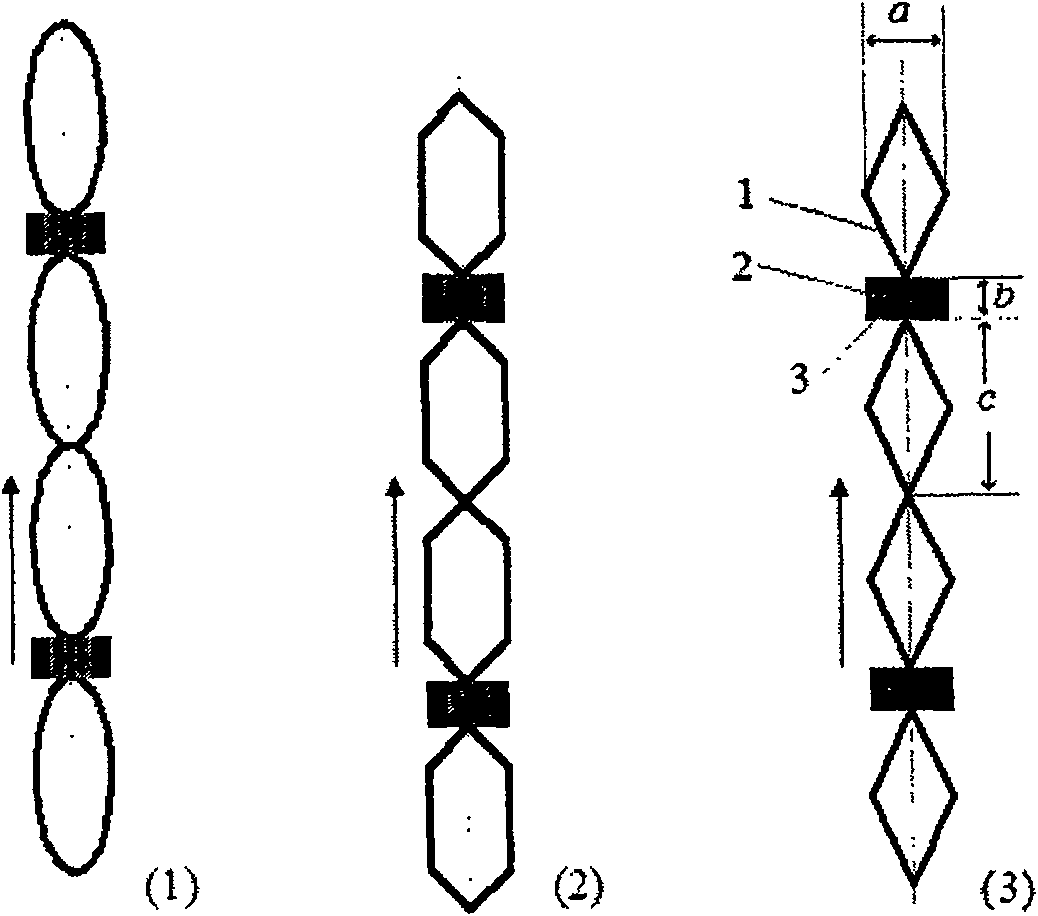

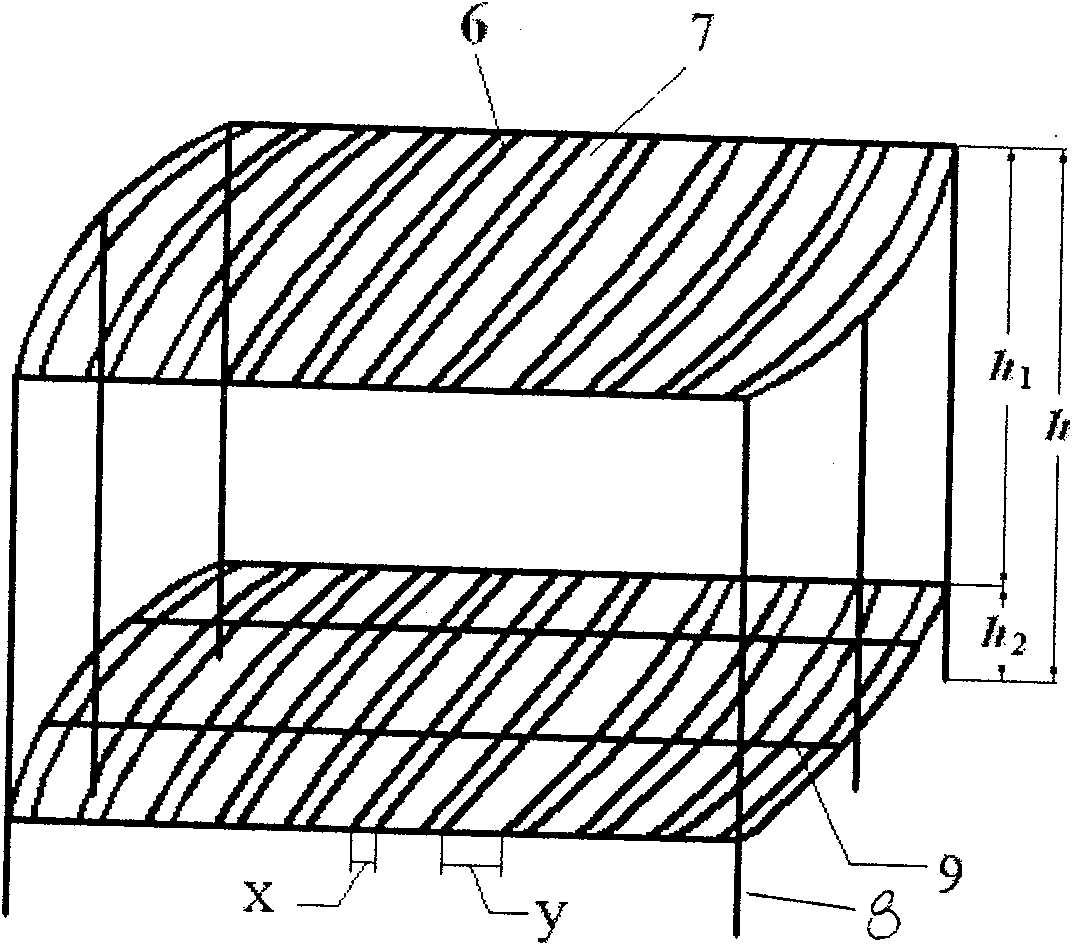

[0025] A diversion tank-shaped catalyst structured packing assembly in a plate-type reactive distillation tower, which is a component installed on the tray plate of the reaction section of the plate-type reactive distillation tower. It has a support frame composed of a 5mm diameter stainless steel rod, supporting The shape of the horizontal plane of the frame is that the two opposite sides are straight lines with a distance of 210 mm, and the other set of two opposite sides are arcs with a center distance of 300 mm, which matches the shape of the gas-liquid mass transfer area of the tray, such as image 3As shown, the supporting frame is high 120mm, wherein the height of the catalyst insert groove is 95mm (that is, adapting to the liquid level height of the tray during operation), and there are fixed legs 8 under the bottom surface of the...

Embodiment 2

[0027] Embodiment 2: Esterification produces butyl acetate

[0028] A reactive distillation column with an annual output of 100 tons of high-purity butyl acetate, with an inner diameter of 300mm and a tower height of 6.5m. The height of the upper rectifying section and the lower stripping section are both 2.0m, and they are filled with industrial conventional structured corrugated packing respectively. The height of the catalytic reaction section in the middle is 2.5m, with 10 sieve trays, the plate spacing is 250mm, the overflow weir is 35mm high, and the tray is equipped with diversion groove-shaped catalyst regular packing components. The filling unit of the catalyst insert adopts an elliptical cylinder with a major axis of 48mm and a minor axis of 16mm. The height of the insert is 110mm, and the height from the bottom to the tray is 20mm; the width of the card slot is 18mm, and the average flow channel width is 26mm. The catalyst adopts strong acid ion resin with an avera...

Embodiment 3

[0031] In this embodiment, compared with the traditional process of rectification and separation after catalytic reaction first, the primary conversion rate of acetic acid is increased from 68% to more than 90%, and the conversion rate is increased by more than 20%, which greatly improves the production efficiency and realizes the The integration of catalytic reaction and rectification separation in the rectification tower. In terms of economic benefits, the energy consumption of a single tower is reduced by more than 30%, the equipment investment is reduced by about 40%, the production capacity is increased by 1.5 times, and the comprehensive unit production cost of butyl acetate is reduced by 25%. Embodiment 3: transesterification produces biodiesel

[0032] A reactive distillation simulation tower with an annual output of 80 tons of fatty acid methyl ester has an inner diameter of 250mm and a tower height of 6.0m. The height of the upper rectifying section and the lower st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com