Method capable of preparing few-layer graphene powder in batches

A technology of few-layer graphene and graphene powder, which is applied in the energy field, can solve the problems of poor electrical conductivity and easy agglomeration of graphene, and achieve the effects of good crystallinity, preventing a large amount of agglomeration, and facilitating rapid washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of few-layer graphene powder:

[0032] (1) Graphene oxide: Using the Hummers method, mix 50g of natural graphite with 25g of sodium nitrate in an ice bath, add 1.15L of concentrated sulfuric acid, then add 150g of potassium permanganate, react for 2 hours, heat up to 35°C for 50 minutes , then add 0.75L of deionized water, keep at 90-100°C for 20-30 minutes, then add 0.15L of hydrogen peroxide and 7L of deionized water to obtain a bright yellow graphite oxide solution; after that, use 5% sulfuric acid solution and deionized The water is alternately centrifuged until there is no sulfate ion, pH=5-6, and a pure graphite oxide solution is obtained; finally, graphite oxide is ultrasonically treated to prepare a graphene oxide solution with a certain concentration.

[0033] (2) Hydrazine hydrate reduction: Using hydrazine hydrate reduction method, add 2L deionized water to 2L 0.5mg / mL graphene oxide solution, add 1.4 mL hydrazine hydrate (mass fractio...

Embodiment 2

[0037] The preparation process of few-layer graphene powder:

[0038] (1) Graphene oxide: Same as Embodiment 1.

[0039] (2) Reduction of hydrazine hydrate: same as embodiment one.

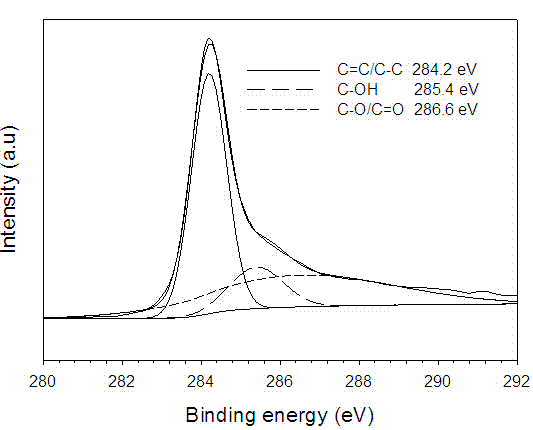

[0040] (3) Flocculation floating suction filtration: use 5% hydrochloric acid solution by mass fraction as the flocculation floating agent, mix 1 volume of graphene colloid solution with 2 volumes of 5% hydrochloric acid solution, and let stand at room temperature (-25°C) for 1 Hours, graphene slowly gathers, floats above the solution, washes with deionized suction filtration water, removes chloride ions, and then washes and freeze-dries to obtain graphene powder reduced by hydrazine hydrate, with a specific surface area of about 346.1 m 2 / g, the conductivity is about 370.7 S / m.

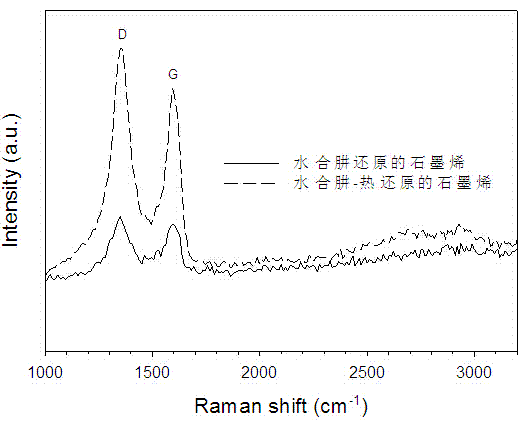

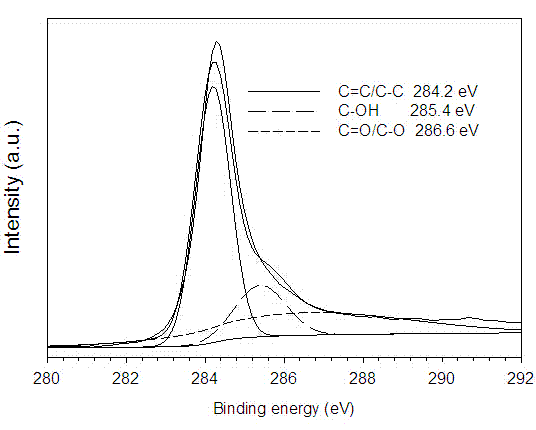

[0041] (4) Thermal reduction treatment: Put the dried graphene reduced by hydrazine hydrate into a tube furnace, raise the temperature at a rate of 10°C / min under the protection of nitrogen, keep it at 1050°C for 1 ...

Embodiment 3

[0043] The preparation process of few-layer graphene powder:

[0044] (1) Graphene oxide: Same as Embodiment 1.

[0045] (2) Reduction of hydrazine hydrate: same as embodiment one.

[0046] (3) Flocculation floating suction filtration: use 5% sodium hydroxide solution as the flocculation floating agent, mix 1 volume of graphene colloid solution with 2 volumes of 5% sodium hydroxide solution, room temperature (-25°C ) to stand still for 1 hour, graphene slowly aggregated and floated above the solution, washed with deionized suction filtration water until pH = 7, and then freeze-dried to obtain graphene powder reduced by hydrazine hydrate, with a specific surface area of about 270.1 m 2 / g, the conductivity is about 168.1 S / m.

[0047] (4) Thermal reduction treatment: Put the dried graphene reduced by hydrazine hydrate into a tube furnace, raise the temperature at a rate of 10°C / min under the protection of nitrogen, keep it at 1050°C for 3 hours, and cool to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com