Method for intensively removing impurity ions in ammonium dihydrogen phosphate by utilizing hydrodynamic cavitation

A technology of ammonium dihydrogen phosphate and hydraulic cavitation, which is applied in the direction of separation methods, chemical instruments and methods, phosphate, etc., to achieve the effect of strengthening the cavitation effect, high efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

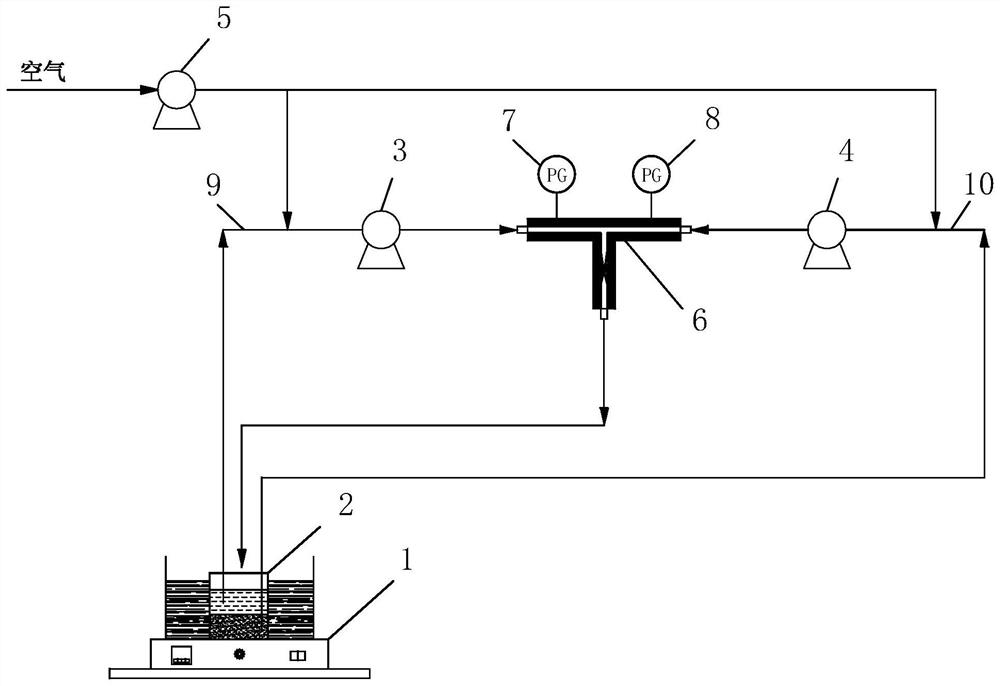

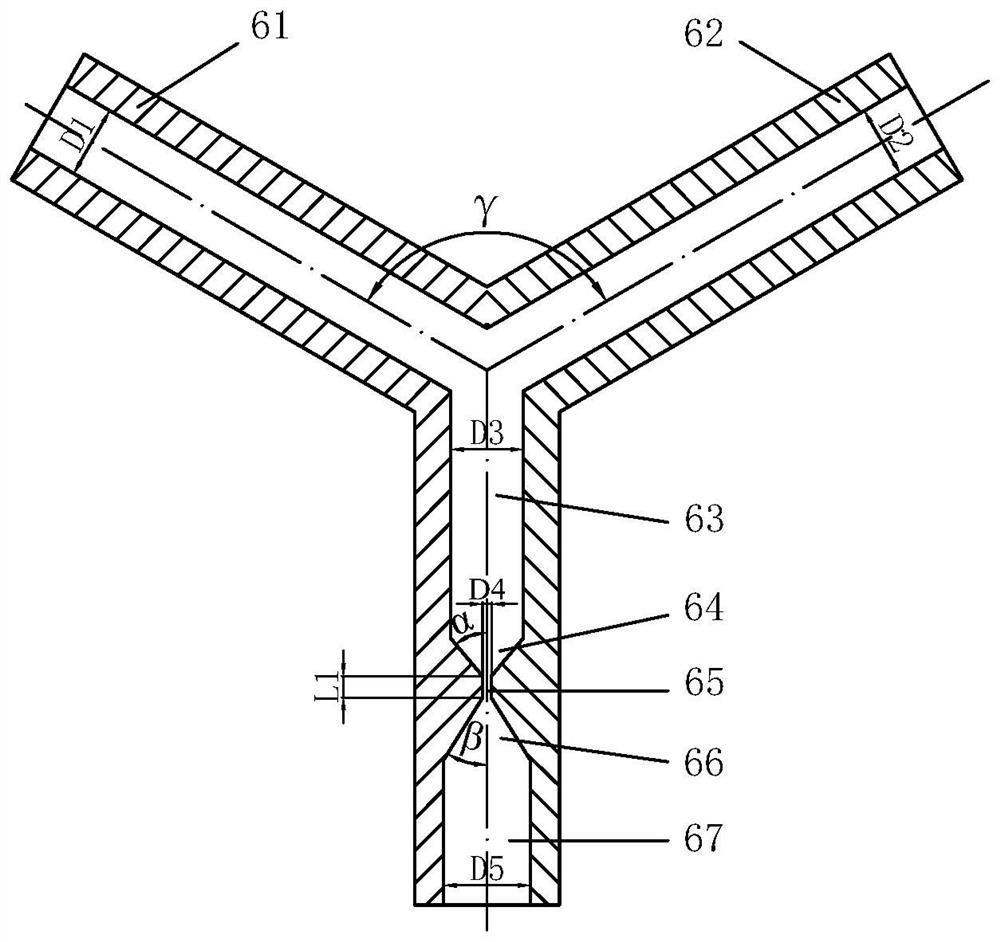

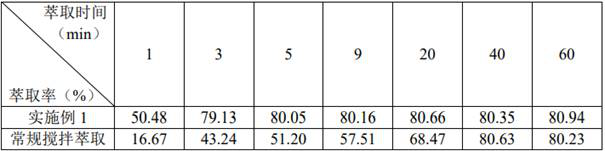

Embodiment 1

[0047]Example 1: using a percussive hydraulic apparatus 3 cavitation geometrical parameters extracted sequence number 1 for schedule, the organic and aqueous phases were preheated to the reaction temperature by the circulation pump respectively the aqueous phase and the organic phase was fed to the feed inlet section ⅰ, entrance ⅱ percussive hydraulic cavitation extraction apparatus, while utilizing plus pump are input gas to the organic phase and aqueous phase feed solution, to control the system pressure by adjusting the circulating speed of the pump feeding the aerated was sequentially through impingement mixing section and reduced diameter section, intensive mixing is obtained at the end of cavitation and the throat section diameter segment generated at the occurrence of the mass transfer process, the extraction fluid is circulated through the stabilization stage is returned to the storage tank; organic phase and the aqueous phase was extracted in a solution percussive hydraul...

Embodiment 2

[0050] Example 2: using the extracted Percussive apparatus having hydrodynamic cavitation No. 6 in Table 1 were geometric parameters, the organic and aqueous phases were preheated to the reaction temperature by the circulation pump respectively the aqueous phase and the organic phase liquid feed conveyor the percussive inlet section of hydrodynamic cavitation extraction equipment ⅰ, entrance ⅱ, while the use of added air pump respectively to the organic phase and the aqueous liquid input gas phase material, to control the system pressure by adjusting the circulating speed of the pump after filling stock solution sequentially through impingement mixing section and reduced diameter section, intensive mixing is obtained at the end of cavitation throat section and enlarged diameter section at the resulting mass transfer process occurs, the fluid returned to the reservoir through the stabilization stage extraction cycle is carried out; the organic phase and the aqueous phase was extrac...

Embodiment 3

[0052] Example 3: use of percussive hydraulic cavitation extraction apparatus having a serial number of Schedule 1 is 2,3,4 geometric parameters, the organic and aqueous phases were preheated to the reaction temperature by the circulation pump respectively the organic and aqueous phase feed was delivered to the percussive hydraulic cavitation extraction apparatus inlet section ⅰ, entrance ⅱ, while the use of added air pump respectively to the organic phase and the aqueous liquid input gas phase material, to control the system pressure by adjusting the circulating speed of the pump, aerated feed liquid sequentially through the impingement mixing section and the reduced diameter section to give strong mixing in the throat section cavitation enlarged diameter section at the end and the generated mass transfer process occurs, the fluid returned to the sump through the stabilization stage circulating extraction; the organic phase and the aqueous phase was extracted solution process con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com