A kind of preparation method of graphene dispersion liquid

A graphene dispersion, graphene technology, applied in chemical instruments and methods, dissolution, mixer and other directions, can solve problems such as inability to meet experiments and industrial production, low dispersion stability, low efficiency, etc., to save dispersion time, The effect of high dispersion stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

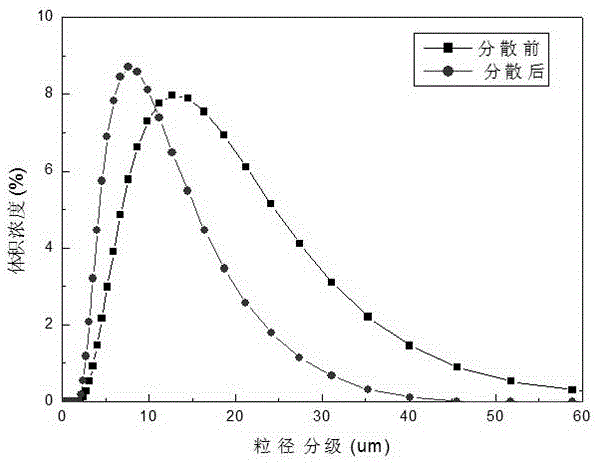

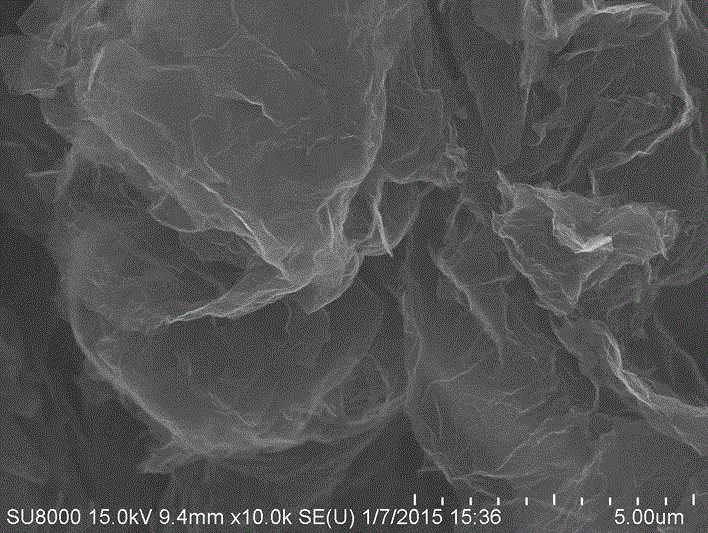

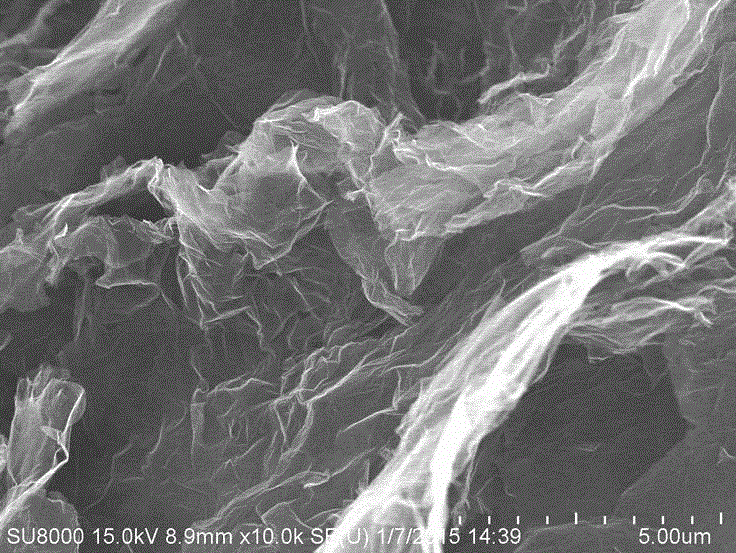

[0025] Get 10g single-layer graphene and 20g polyvinylpyrrolidone, add in 1L N-methylpyrrolidone, fully stir to obtain single-layer graphene mixed solution.

[0026] Turn on the cooling circulating water, set the cooling temperature to 7°C; put the single-layer graphene mixture into the storage tank 3, adjust the speed of the electric agitator 2 to 2000 rpm, and adjust the speed of the colloidal grinding disc 5 and the high-shear dispersing head 6 At 14000 rpm, a focused ultrasonic probe 1 (80 kHz) was added to disperse for 2 h to obtain a single-layer graphene dispersion.

Embodiment 2

[0028] Take 5 g of few-layer graphene and 10 g of polyvinyl alcohol, add them into 1L of distilled water, and stir thoroughly to obtain a few-layer graphene mixture.

[0029] Turn on the cooling circulating water, set the cooling temperature to 5°C; put the few-layer graphene mixture into the storage tank 3, adjust the speed of the electric agitator 2 to 100 rpm, and adjust the speed of the colloidal grinding disc 5 and the high-shear dispersing head 6 At 7000 rpm, add two focused ultrasonic probes 1 (20 kHz, 80 kHz) and disperse for 0.5 h to obtain a few-layer graphene dispersion.

Embodiment 3

[0031] Take 0.2 g of multilayer graphene and 2 g of lauryl polyethylene glycol ether, add them to 2L of absolute ethanol, and stir thoroughly to obtain a multilayer graphene mixed solution.

[0032] Turn on the cooling circulating water, set the cooling temperature to 10°C; put the multi-layer graphene mixture into the storage tank 3, adjust the speed of the electric stirrer 2 to 1000 rpm, and adjust the speed of the colloidal grinding disc 5 and the high-shear dispersing head 6 At 100 rpm, a focused ultrasonic probe 1 (60 kHz) was added for 12 h to disperse to obtain a multilayer graphene dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com