A kind of method utilizing self-vibration cavitation to prepare oligomeric chitosan

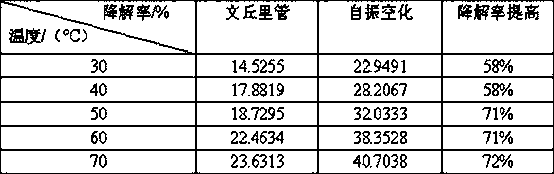

A chitosan oligosaccharide and self-vibration cavitation technology, which is applied in the preparation field of chitosan oligosaccharides, can solve problems such as difficult to achieve efficient energy utilization, and achieve the effects of increased degradation rate, high efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

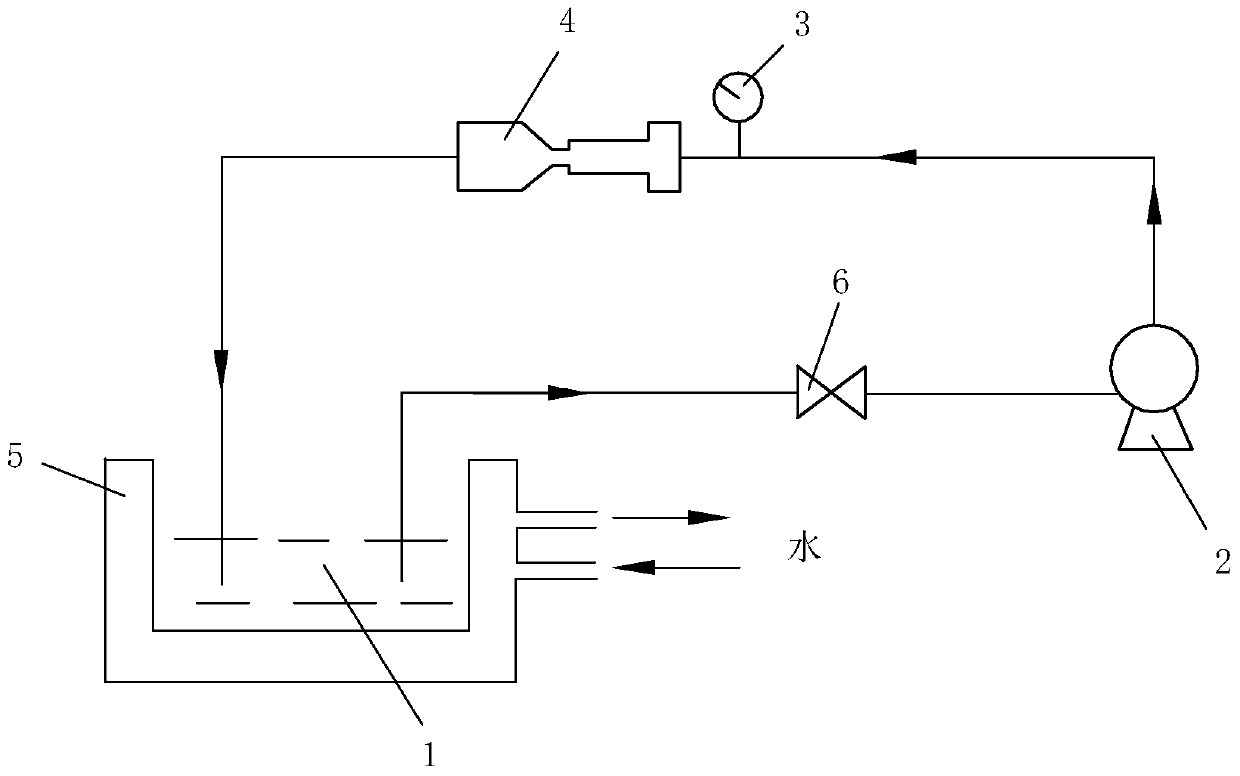

[0030] Embodiment: a kind of method utilizing self-vibration cavitation to prepare oligomeric chitosan comprises the following steps:

[0031] The first step: dissolving chitosan: adding high-molecular-weight chitosan into a solvent and dissolving it to form a chitosan solution, the solvent being one of an aqueous solution of inorganic acid, an aqueous solution of organic acid or a slightly acidic buffer solution, Wherein, the mass concentration of the described inorganic acid aqueous solution or organic acid aqueous solution is 1%-13%, the pH of the buffer solution is 3-5, and the mass concentration of the chitosan solution is 0.5g / L- 5g / L, the relative molecular mass of the high molecular weight chitosan is greater than 2×10 6 , the degree of deacetylation is greater than 60%; the inorganic acid is hydrochloric acid, the organic acid is formic acid, acetic acid, lactic acid or citric acid, and the buffer solution is acetic acid-sodium acetate or citric acid-sodium citrate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com