A kind of silk fibril cracking agent and its preparation and use method

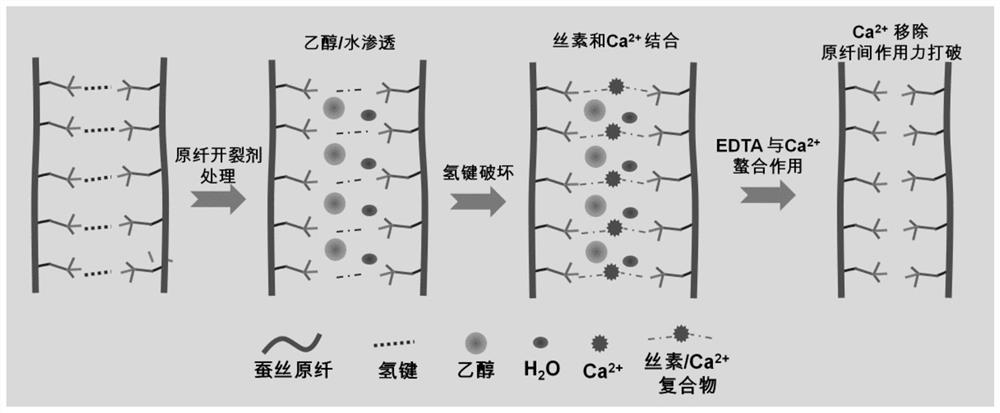

A silk fiber and silk technology, applied in the field of micro-nano materials, can solve the problems of inability to completely break the fibrils, achieve the effects of improving cracking and separation efficiency, simple operation, and mild solvent action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A silk fibril cracking agent and a method for preparing and using the same, the method comprising the steps of:

[0032] S1 preparation solution:

[0033] S11 configures a ternary mixed solution composed of calcium nitrate, ethanol and deionized water. The concentration and ratio of calcium nitrate / ethanol / deionized water are: the concentration of calcium nitrate is 7mol / L, and the ratio of deionized water to alcohol is 1:5;

[0034] S12 configures a solution composed of Tris and EDTA, the ratio is: 10mM Tris and 2mM EDTA;

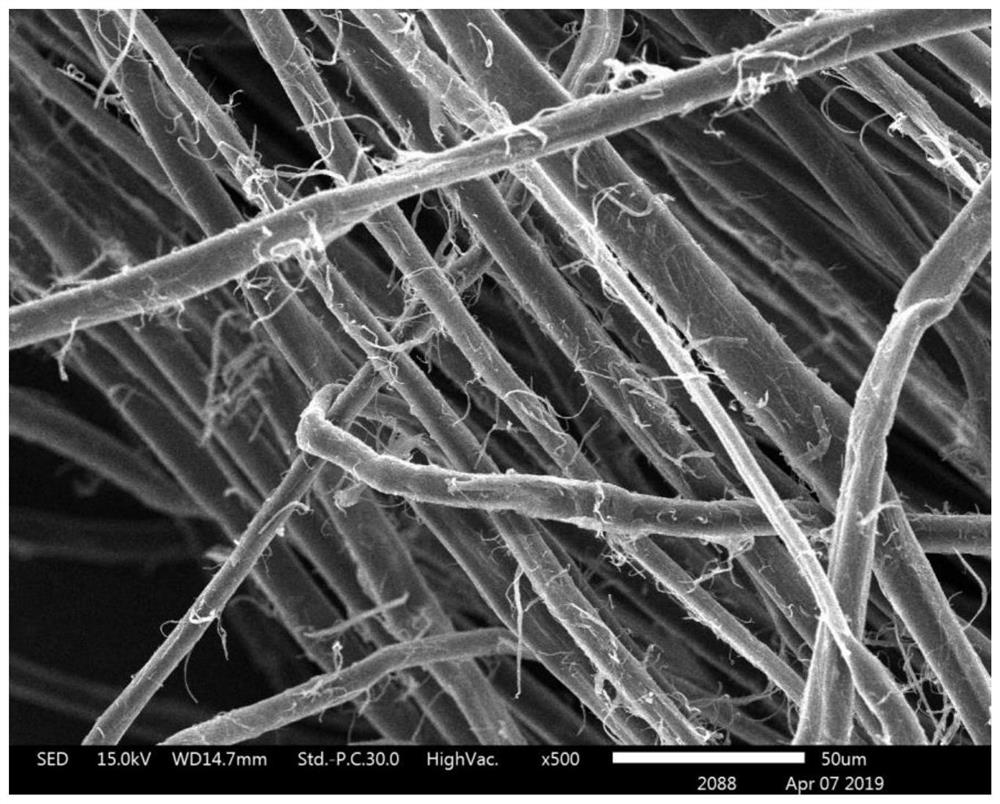

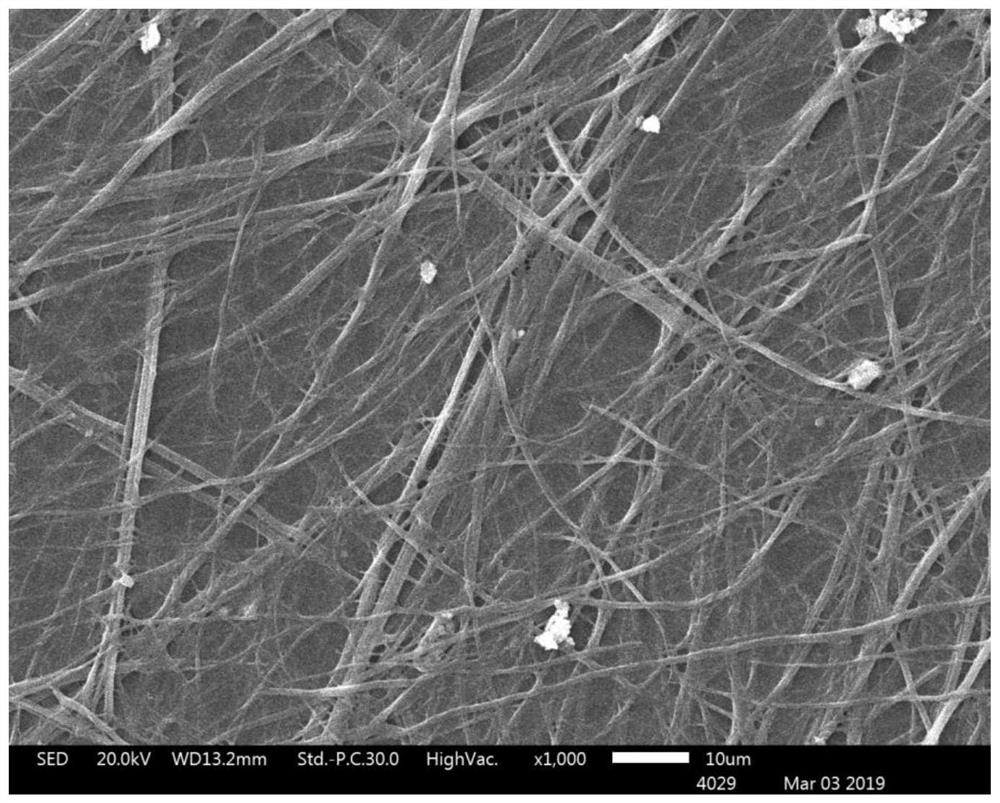

[0035] S2 cracking treatment: immerse the degummed silkworm silk in the ternary solution composed of calcium nitrate / ethanol / deionized water prepared in S11, soak it at 45°C for 3 days, and wash it fully; use the silk fiber treated in the first step Soak in Tris-EDTA solution for 2 hours;

[0036] S3 post-treatment: the fibers obtained in the above step S2 are fully washed and dried to obtain silk with weakened fibril force.

Embodiment 2

[0038] A silk fibril cracking agent and a method for preparing and using the same, the method comprising the steps of:

[0039] S1 preparation solution:

[0040] S11 configures a ternary mixed solution composed of calcium nitrate, ethanol and deionized water. The concentration and ratio of calcium nitrate / ethanol / deionized water are: the concentration of calcium nitrate is 5mol / L, and the ratio of deionized water to alcohol is 1:3;

[0041] S12 configures a solution composed of Tris and EDTA, the ratio is: 50mM Tris and 10mM EDTA;

[0042] S2 cracking treatment: immerse the degummed tussah silk in the ternary solution composed of calcium nitrate / ethanol / deionized water prepared in S11, soak it at 60°C for 5 days, and wash it fully; use the silk fiber after the first step treatment Soak in Tris-EDTA solution for 0.5h;

[0043] S3 post-treatment: the fibers obtained in the above step S2 are fully washed and dried to obtain silk with weakened fibril force.

Embodiment 3

[0045] A silk fibril cracking agent and a method for preparing and using the same, the method comprising the steps of:

[0046] S1 preparation solution:

[0047] S11 configures a ternary mixed solution composed of calcium nitrate, ethanol and deionized water. The concentration and ratio of calcium nitrate / ethanol / deionized water are: the concentration of calcium nitrate is 4mol / L, and the ratio of deionized water to alcohol is 1:1;

[0048] S12 configures a solution composed of Tris and EDTA, the ratio is: 1mM Tris and 1mM EDTA;

[0049]S2 cracking treatment: immerse the degummed tussah silk in the ternary solution composed of calcium nitrate / ethanol / deionized water prepared in S11, soak for 7 days at 30°C, and wash fully; the silk fiber after the first step is treated with Soak in Tris-EDTA solution for 4h;

[0050] S3 post-treatment: fully wash and dry the fibers treated in the above step S2 to obtain silk with weakened fibril force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com