Preparation process and system for ultrasonic reinforced supercritical CO2 extraction of tussah pupa oil

A technology of ultrasonic enhancement and preparation technology, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems of restricting large-scale industrial application, high extraction temperature and high pressure, and achieve lower temperature, lower extraction pressure and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

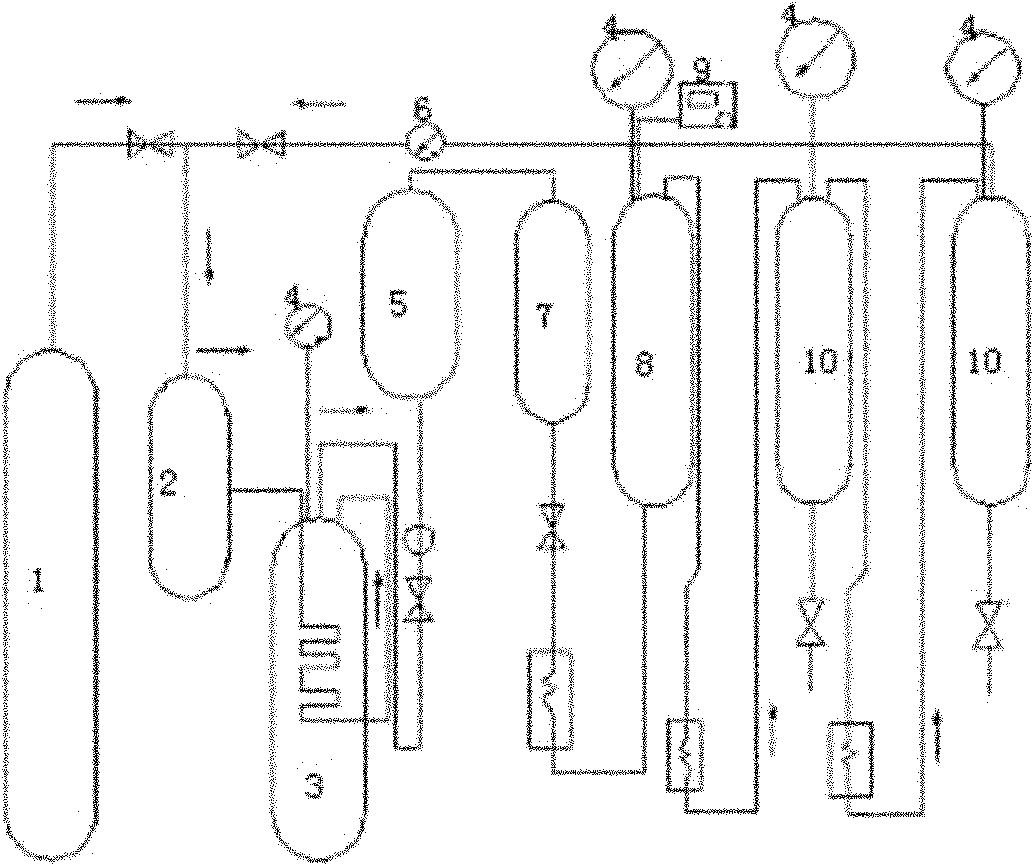

[0029] A tussah silkworm chrysalis oil ultrasonically enhanced supercritical CO 2 The preparation process of extraction is characterized in that: the steps of the preparation process are:

[0030] (1). Raw material pretreatment: use the tussah silkworm chrysalis of the genus Tussah species produced in Dandong City, Liaoning Province, and the variety is "Kangda". Tussah silkworm chrysalis powder.

[0031] (2). Put the tussah silkworm chrysalis powder obtained in step (1) into the extraction kettle, and when the temperature reaches 40-50°C, turn on the CO 2 Air is supplied from the cylinder, and when the extraction pressure reaches 18-25MPa, the flow rate is adjusted, and tussah silkworm chrysalis oil is extracted at constant temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com