Method and system for pretreating lateritic nickel ore

A technology for laterite nickel ore and pretreatment, applied in the metallurgical field, can solve the problems of large water content and difficult to handle, and achieve the effect of good water removal effect, simple process flow and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

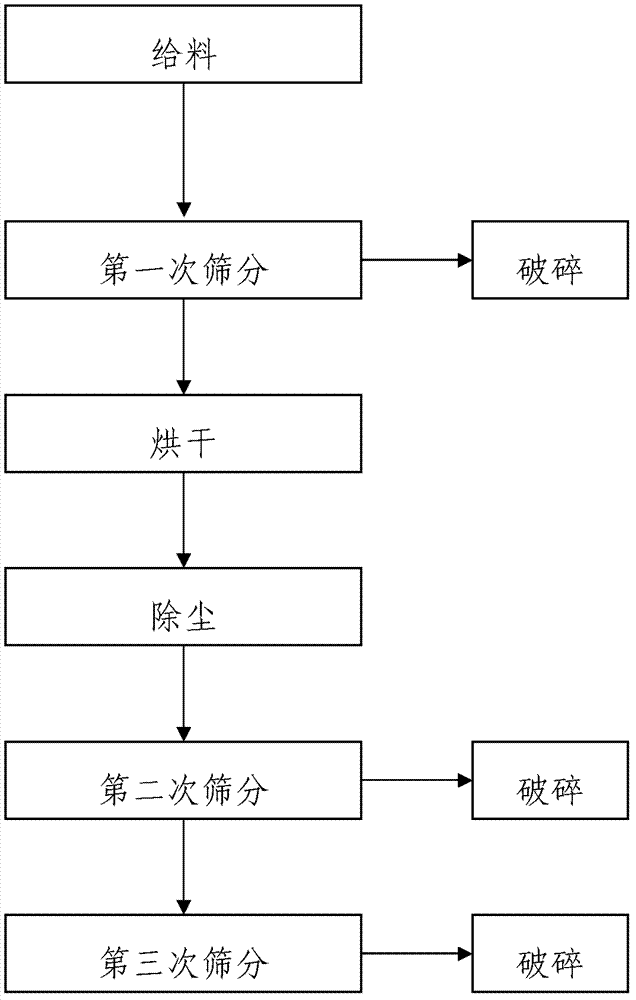

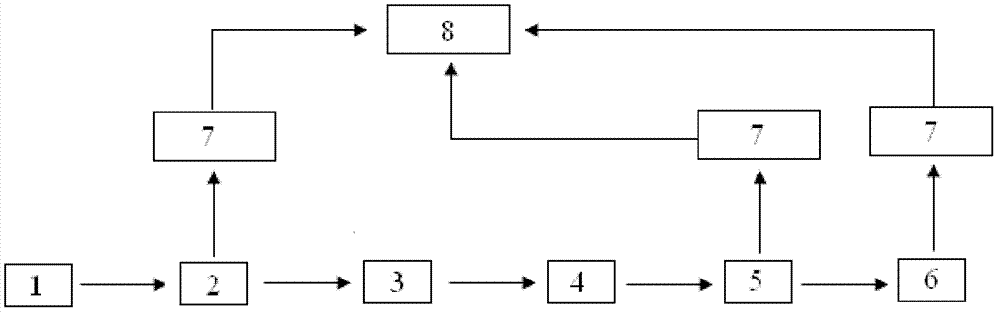

[0032] (1) if figure 2 As shown, wet laterite nickel ore (average nickel 1.87%, iron 12%, crystal water 21%, attached water 15%, containing 40% stones, of which more than half diameter is more than 300mm, bonded in laterite nickel ore) , enter the 1.2m×6m apron feeder 1 (steel plate chain belt structure) through a forklift and enter the B1000 feeding belt. The raw materials are sent to the 1.8m×5.4m vibrating screen 2 (screen hole 200×200mm), and the high-nickel lump ore with a diameter greater than 200mm is screened out, and the lump ore is transported to the jaw crusher 7 to be crushed to less than 150mm.

[0033] (2) The laterite nickel ore with less than 200mm of vibrating sieve enters the cylindrical drying kiln 3 of 3.5×40m (diameter×length) through the belt conveyor. The inner wall of the drying kiln body 30 is evenly distributed with 20cm high , a steel material baffle 31 with a width of 25 cm, and the distance between each material baffle and the surrounding materia...

Embodiment 2

[0038] In the steps (1), (3), and (4), the lump ore is not subjected to jaw crushing, and the rest are the same as steps (1) to (4) of Embodiment 1.

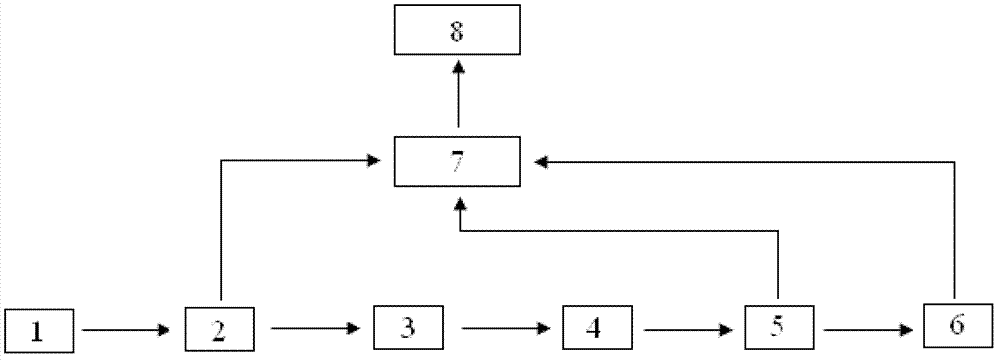

[0039] (5) The aforementioned lump ore is transported to the same jaw crusher 7 through a belt, crushed to a diameter of 50-100 mm, and then enters a hammer crusher 8, hammered to a diameter of less than 10 mm, and stacked for standby, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com