Ultrasonic cavitation device

A cavitation and ultrasonic technology, applied in the field of ultrasonic cavitation, can solve the problems of low efficiency of ultrasonic cavitation devices, and achieve the effect of high space-to-volume ratio and high cavitation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Other characteristics, characteristics and advantages of the present invention will be more apparent after the following detailed description of the embodiments of the present invention by way of examples in conjunction with the accompanying drawings.

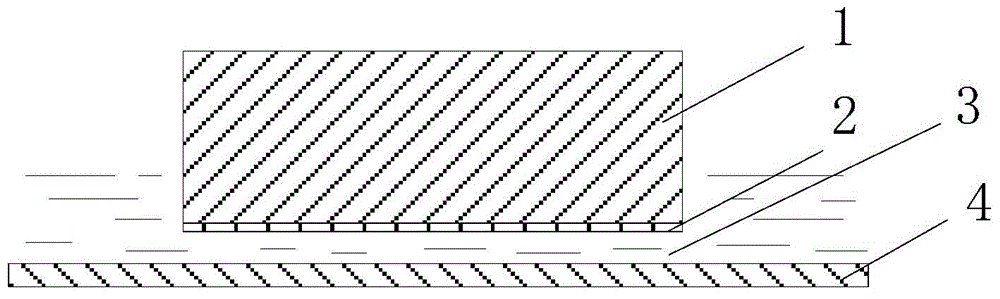

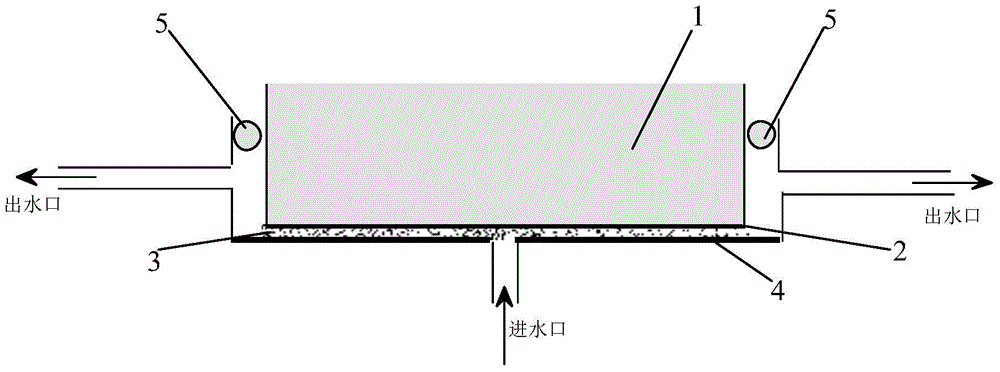

[0022] figure 1 It is a schematic structural diagram of an ultrasonic cavitation device provided by an embodiment of the present invention. Such as figure 1 As shown, the ultrasonic cavitation device includes: a vibrating body 1 and a reflector 4 , wherein the vibrating body 1 has a radiation surface 2 at one end, and a liquid thin layer 3 is formed between the radiation surface 2 and the reflector 4 . The vibration body 1 is used to convert electric energy into ultrasonic waves, and the ultrasonic waves enter into the liquid thin layer 3 through the radiation surface 2 and form an acoustic field in the liquid thin layer 3 .

[0023] The reflector 4 reflects the ultrasonic waves radiated by the radiating surface 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com