Ultrasonic wound debrider probe and method of use

a technology of ultrasound and wound debrider, which is applied in the field of ultrasonic surgical instruments, can solve the problems of reducing the operating time of the procedure, and achieve the effects of improving the liquid flow, reducing the bulk temperature rise of the tissue, and increasing the effectiveness of the prob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

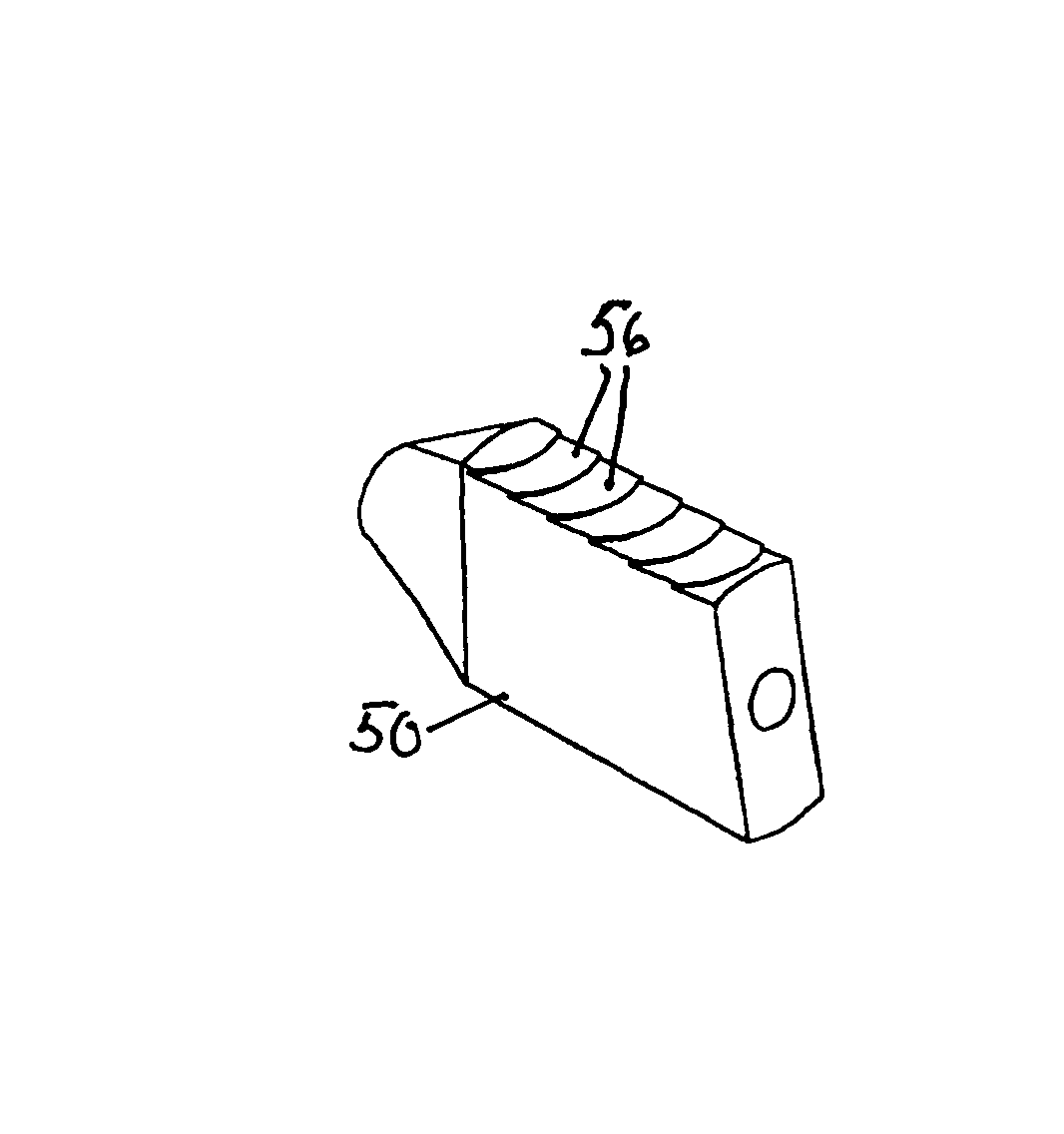

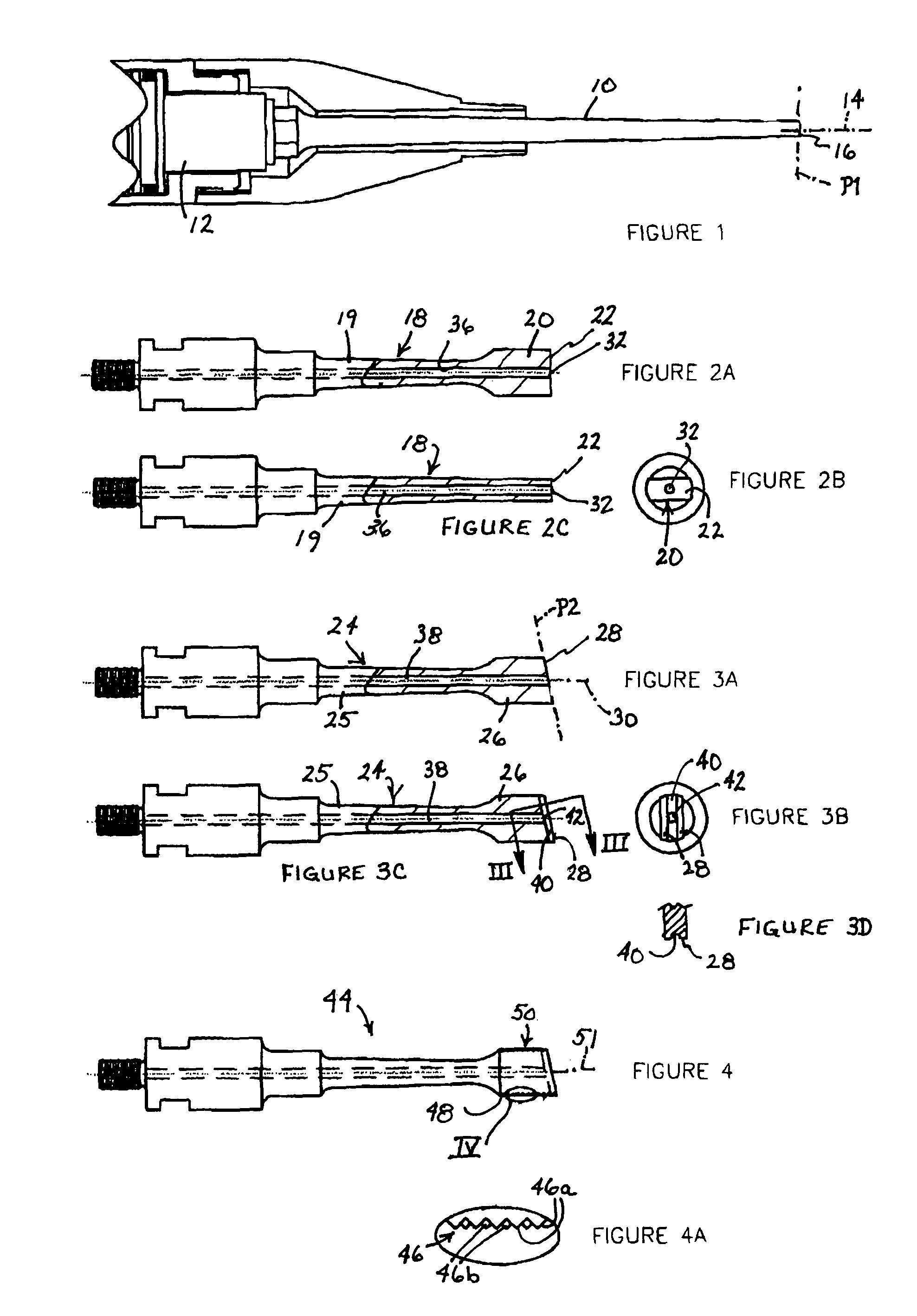

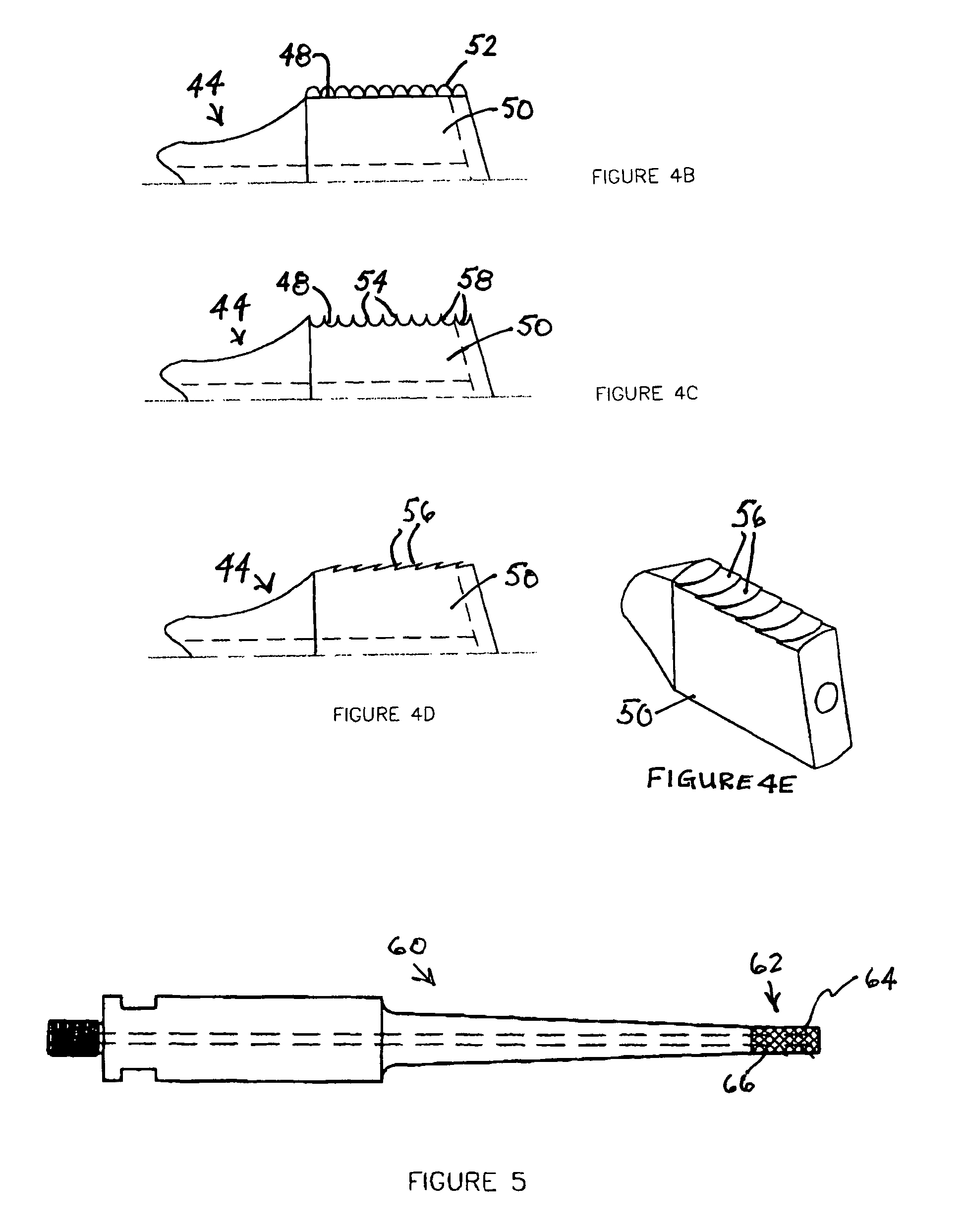

[0058]Several probes are disclosed which embody the improvements described herein. FIG. 1 shows a probe 10 which is known to the art and is currently manufactured for use with an ultrasonic aspirator. This probe 10 is basically shaped with an exponential or Gaussian taper. Probe 10 is cannulated and has an integral male thread (not shown) at the proximal end (proximate the operator). This thread communicates with a female threaded bore (not illustrated) in the transducer 12. By tightening the probe 10 onto the transducer 12 and using standard wrenches for final torquing, the transducer and probe essentially become one resonant body. Bores of the probe 10 and transducer 12 communicate with one another. The probe 10 is generally constructed of an acoustically efficient metal or ceramic. Titanium is the most commonly used material, but other material has been employed with success. Material choice does not have a significant impact upon the embodiments of this disclosure.

[0059]The dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com