Ultrasonic dispersion control device using cavitation intensity feedback and ultrasonic dispersion control method thereof

A control device and ultrasonic dispersion technology, applied in the ultrasonic field, can solve the problems of low control precision, no output detection method, and extensive closed-loop control strategy, and achieve the effects of good control effect, reasonable design, and stable output output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

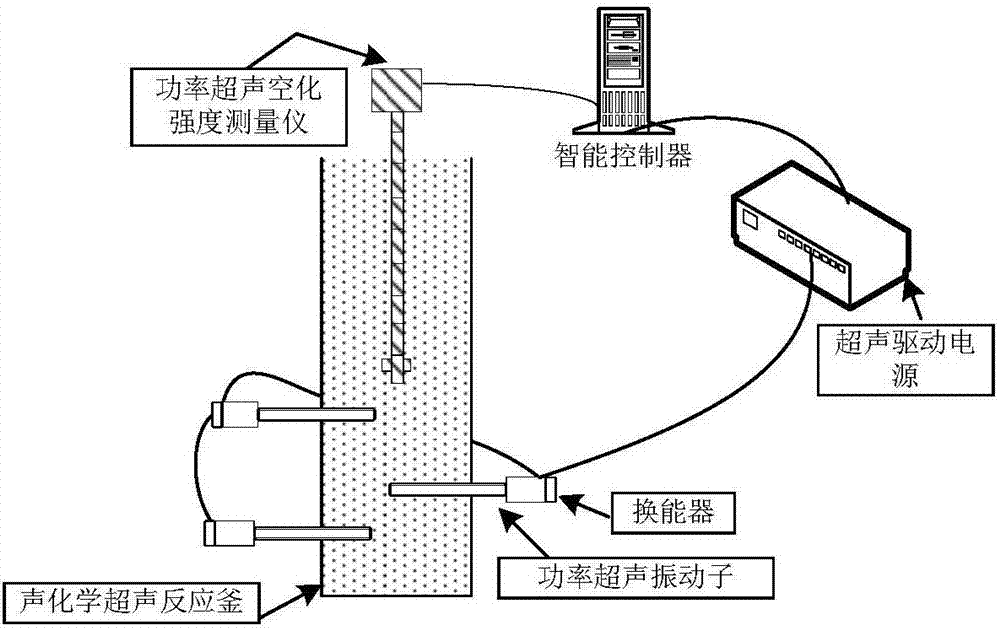

[0032] like figure 1 As shown, an ultrasonic dispersion control device using cavitation intensity feedback, including a controller, an ultrasonic power supply, an ultrasonic cavitation intensity measuring instrument, a transducer and an ultrasonic vibrator;

[0033] The control signal end of the controller is connected to the control signal input end of the ultrasonic power supply, the power output end of the ultrasonic power supply is connected to the power input end of each transducer, and the signal output end of each transducer is connected to the ultrasonic vibrator , the ultrasonic vibrator is inserted into the chemical ultrasonic reaction kettle, the ultrasonic cavitation intensity measuring instrument is set in the chemical ultrasonic reaction kettle, and the signal output terminal of the chemical ultrasonic reaction kettle is connected to the signal input terminal of the controller;

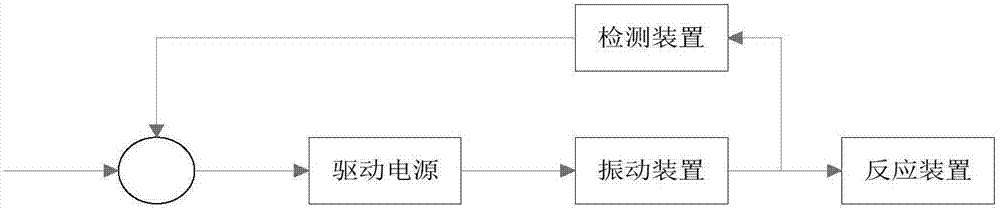

[0034] like image 3 As shown, an ultrasonic dispersion control method using cavita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com