Hydraulic/ultrasonic coupling cavitation device

An ultrasonic coupling and cavitation technology, applied in the field of cavitation, can solve the problem that the cavitation intensity of hydraulic cavitation is not as good as that of ultrasonic cavitation, and achieve the effect of improving efficiency and increasing cavitation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

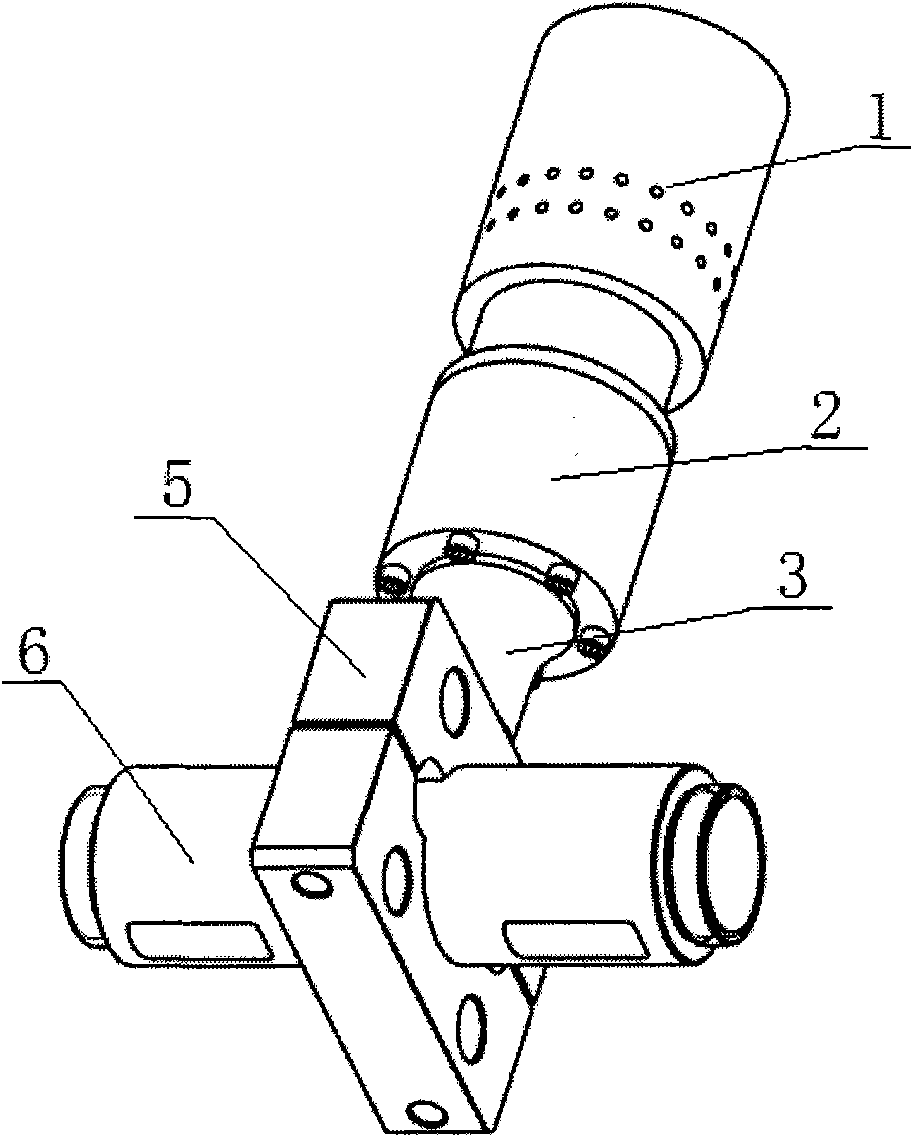

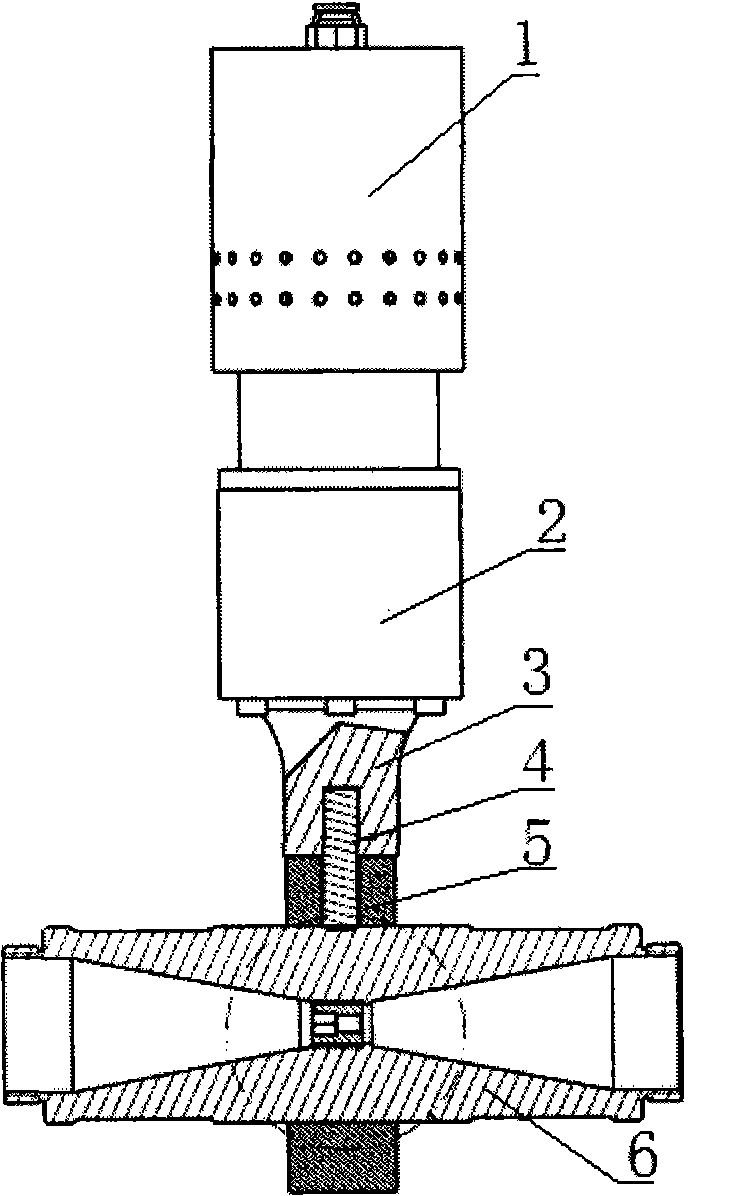

[0025] Hydraulic / ultrasonic coupled cavitation devices such as Figure 1~3 As shown, it includes a hydraulic cavitation mechanism and an ultrasonic functional mechanism, and an ultrasonic functional mechanism is installed on the hydraulic cavitation mechanism. The hydraulic cavitation mechanism can be a Venturi tube 6 . The ultrasonic functional mechanism includes an ultrasonic transducer 1, a connecting flange 2, a horn 3 and a functional fixture 5. The ultrasonic transducer 1 is connected to the horn 3 through the connecting flange 2, and the horn 3 is connected to the functional fixture 5. , the Venturi tube 6 is clamped by the functional clamp 3 . The connecting flange 2 is set on the node position. The functional fixture 5 is clamped at the liquid whistle or the lower part of the Venturi tube 6, through the organic combination of the piezoelectric ultrasonic cavitation and the hydraulic cavitation of the Venturi tube 6 itself, without interfering with each other, the ca...

Embodiment 2

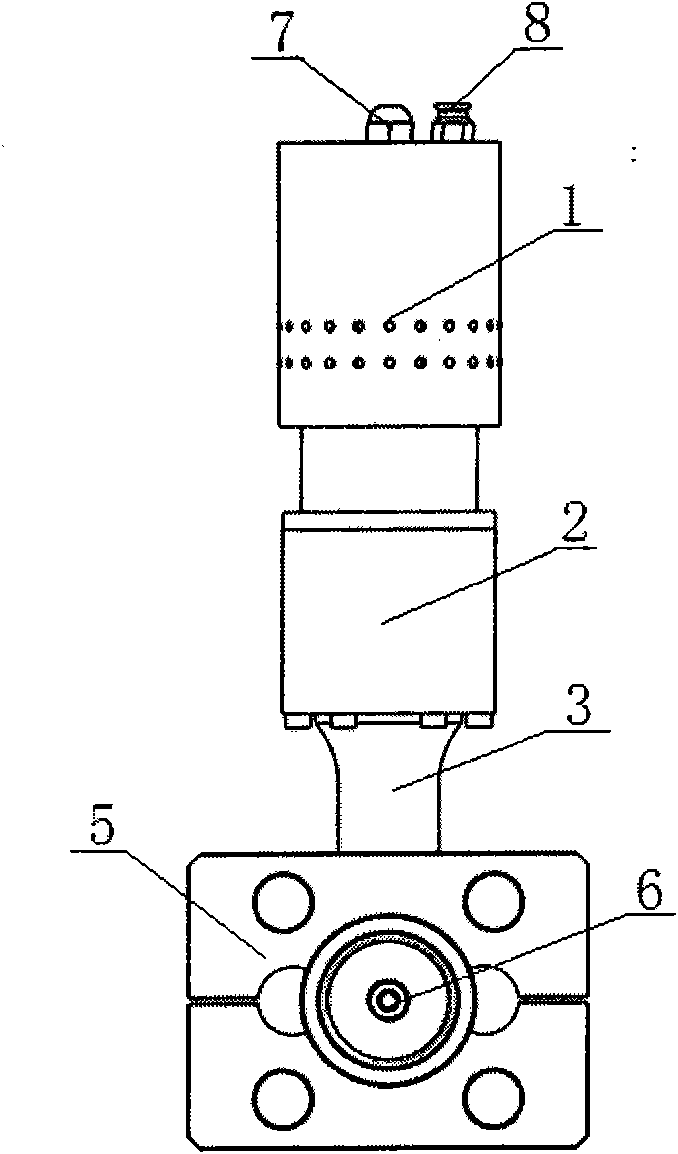

[0028] Hydraulic / ultrasonic coupled cavitation devices such as Figure 6~7 As shown, the orifice plate 9 is clamped in the functional fixture 5, and the holding point is located at or below the orifice plate. A close-hole flange is provided at the port of the orifice plate 9 for easy connection.

[0029] The ultrasonic transducer 1 mentioned above can be piezoelectric ceramic type or magnetostrictive type, its frequency band is: 10khz-130khz, single power: 5-5000w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com