Soymilk grinder with ultrasonic wave device

A technology of ultrasonic wave and soybean milk machine, which is applied in the field of equipment for making soybean milk, which can solve the problems of maintenance and replacement, increased weight, volume, unsafety, and increased cost, and achieves improved cleaning methods, faster boiling speed, and reduced foam. The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

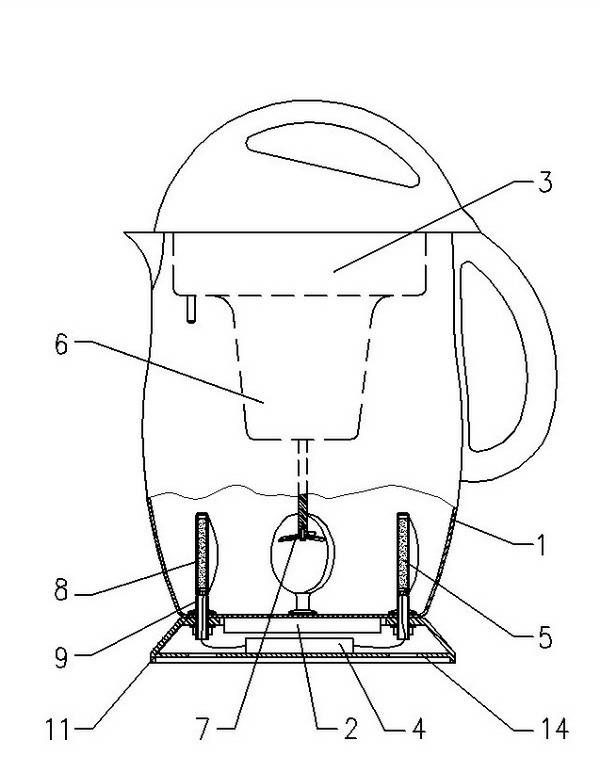

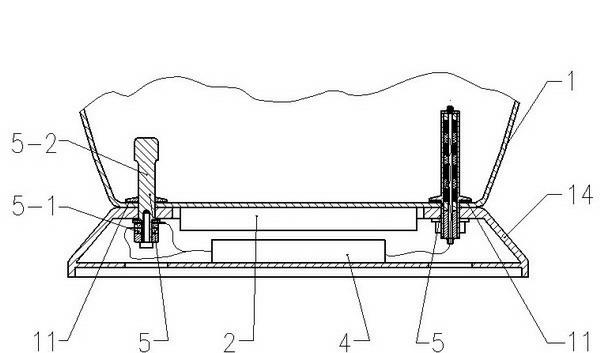

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

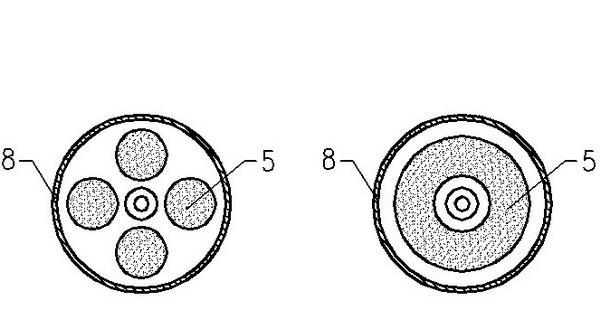

[0021] Such as figure 1 As shown, an ultrasonic transducer 5 composed of a transducer 5-1 and a horn 5-2 is installed on the machine head 3, the transducer 5-1 is in the sealed housing of the machine head, and the horn 5 -2 extends into the water in the cup body 1 . The ultrasonic generator 4 is installed in the sealed housing of the handpiece 3 . The high-frequency oscillation signal generated by the ultrasonic generator 4 is converted into high-frequency mechanical oscillation by the transducer 5-1, and transmitted to the water in the cup body by the horn, so that it produces an "ultrasonic cavitation" effect and Other ultrasonic effects, cleaning the soymilk residue and attachments inside the cup and on various parts of the machine head. Or in the process of soybean milk processing, use ultrasonic effect to process materials and finished products.

[0022] It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com