Large channel side slope bed course spreading machine

A paver and channel technology, applied in artificial waterways, water conservancy projects, construction, etc., can solve the problems of complex structure of the main engine, high requirements for construction conditions, and high cost, and achieve the goal of improving project quality, reducing labor input, and reducing project costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The specific implementations of the present invention will be described below in conjunction with the accompanying drawings.

[0027] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

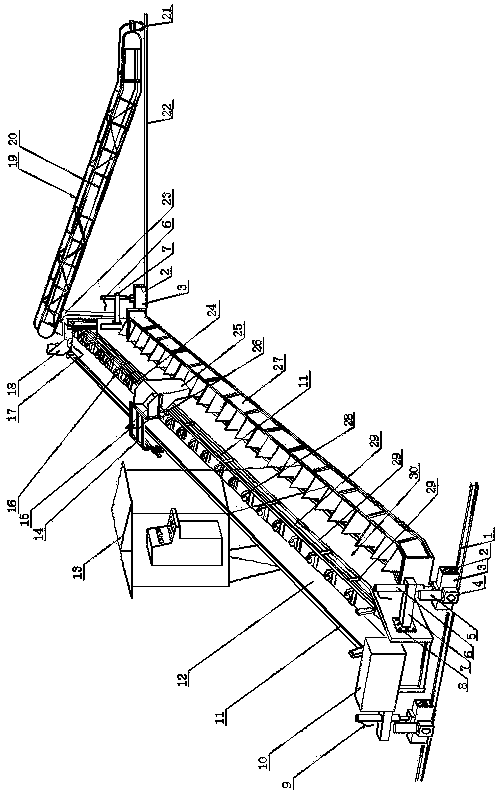

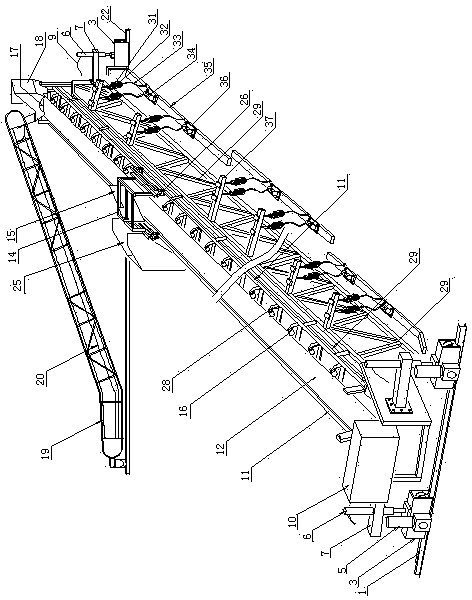

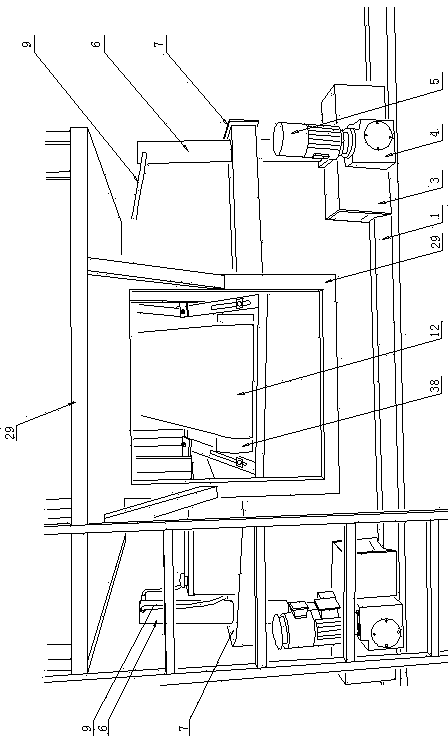

[0028] Such as figure 1 As shown in -11, the large-scale channel slope cushion paver consists of four parts: feeding, walking and lifting, distributing, and vibration forming.

[0029] Walking lifting part: such as figure 1 , 2 , 3, 6, 9, and 10, respectively by the canal shoulder guide rail 22 laid along the canal shoulder and the canal bottom, the canal bottom guide rail 1, the walking wheel set 2 erected on the second guide rail, the Π Shaped wheel box 3, the piston rod of the hydraulic oil cylinder 6 that is installed on the wheel box 3 upper end face, and the horizontal support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com