Time-and-space-area sampling tobacco-re-drying homogenization processing method

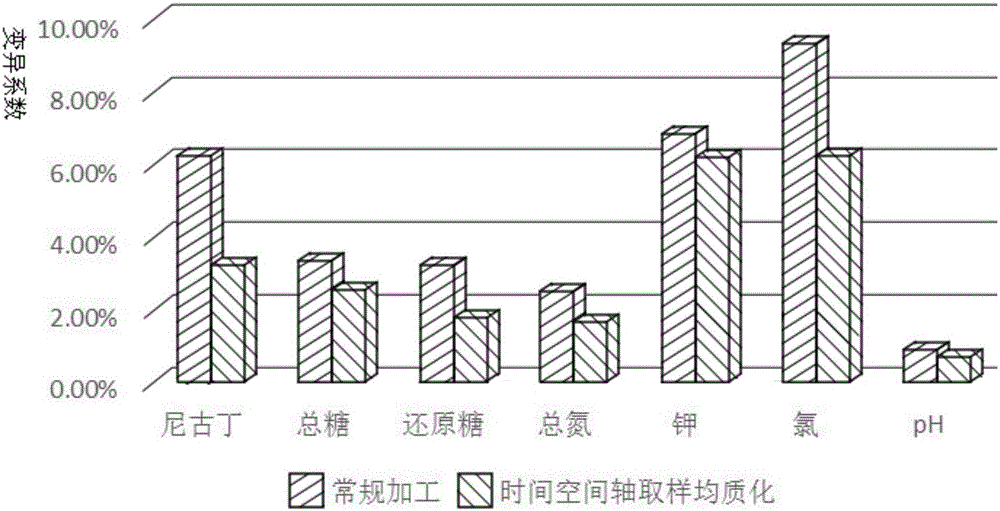

A processing method and a technology for re-curing tobacco leaves, which are applied in the fields of tobacco, tobacco preparation, measuring devices, etc., can solve the problems of increased economic cost and process complexity, unspecific algorithms, and difficult promotion, etc., so as to improve the detection speed and sampling. The effect of representativeness, small process change and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Using 20,000 tons of raw tobacco in central Yunnan from the threshing and re-baking factory, the average formula was produced according to the time-space area quartering sampling method. The processing formula list, the specific distribution of raw tobacco origin, grade, quantity and proportion are shown in Table c. Show.

[0057] Table c Yunnan Tobacco Leaf Formula Proportion Table

[0058]

[0059]

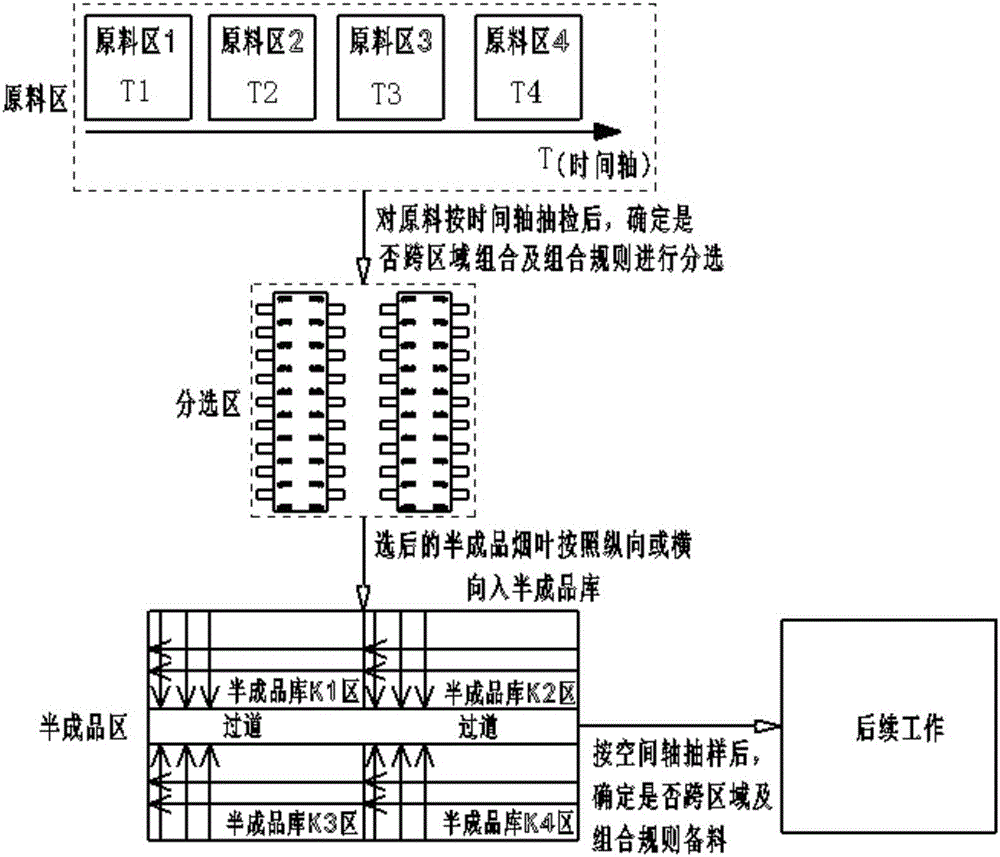

[0060] Divide the raw tobacco into 4 time zones T1, T2, T3, T4 according to the storage time, divide them equally in order of storage time, and determine the sampling quantity of each time zone according to the quantity distribution of the time zone. Take 200-500 tons of raw tobacco in the area as a raw tobacco sample; each raw tobacco sample covers all stacks in the corresponding time zone, and 2kg of tobacco leaf samples are taken from each raw tobacco sample for online near-infrared rapid scanning detection. The detection time is 10s. Due to the large amount of ...

Embodiment 2

[0093] Using 50,000 tons of raw tobacco from the threshing and redrying plant, the average formula was produced according to the five-point sampling method in time and space. The processing formula sheet, the specific distribution of raw tobacco origin, grade, quantity and proportion are shown in Table h.

[0094] Table h Processed Tobacco Leaf Formula Ratio Table

[0095]

[0096] Divide the raw tobacco into five time zones T1, T2, T3, T4, T5 according to the storage time, divide them equally in order of storage time, and determine the sampling quantity of each time zone according to the number distribution of the time zone. Take 200-500 tons of raw tobacco in each time zone as a raw tobacco sample; each raw tobacco sample covers all stacks in the corresponding time zone, and take 2kg of tobacco leaf samples in each raw tobacco sample for online near-infrared fast scanning Detect, the detection time is 10s, multiple sampling and average value are obtained to obtain the tob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com