Full-automatic copper belt machine, terminal machine and method for feeding sheaths by pressing copper belt riveting terminals

A terminal crimping and fully automatic technology, which is applied in the direction of connection, connection by deformation, electrical components, etc., can solve the problems of low production efficiency, high labor cost, and inability to realize automation, etc., and achieve a simple structure and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

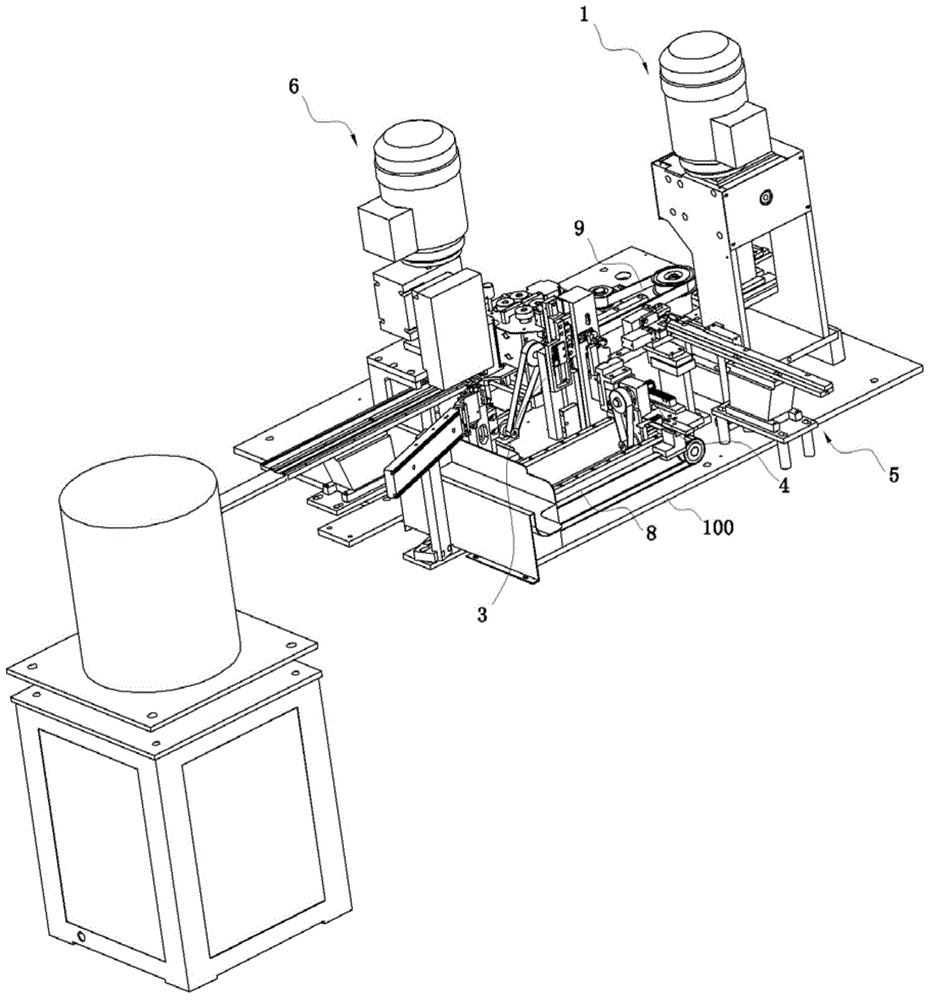

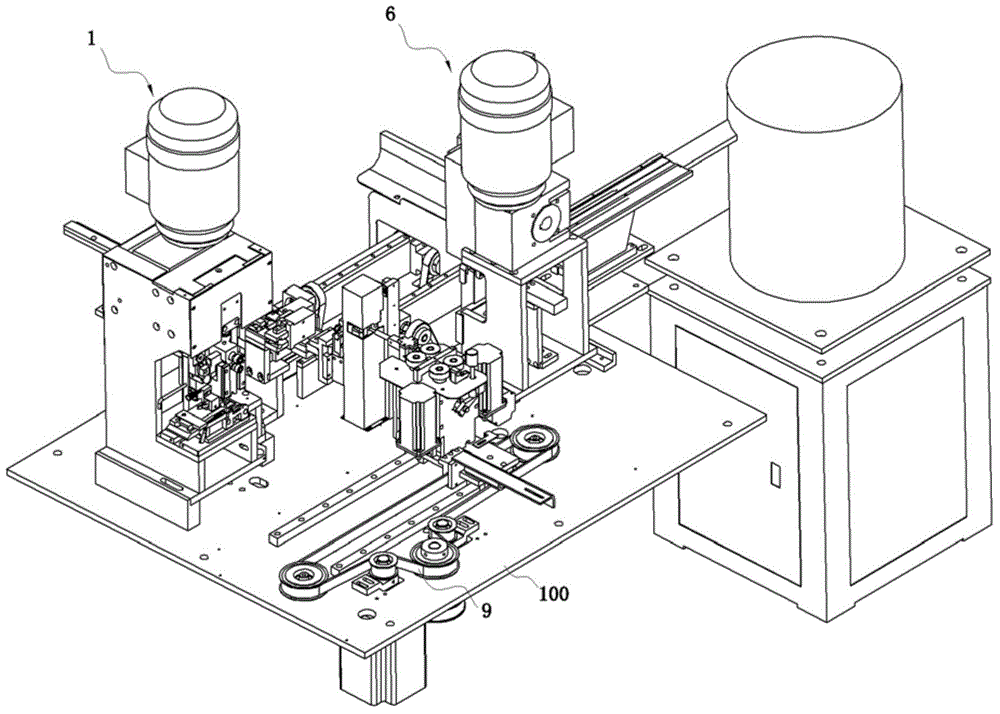

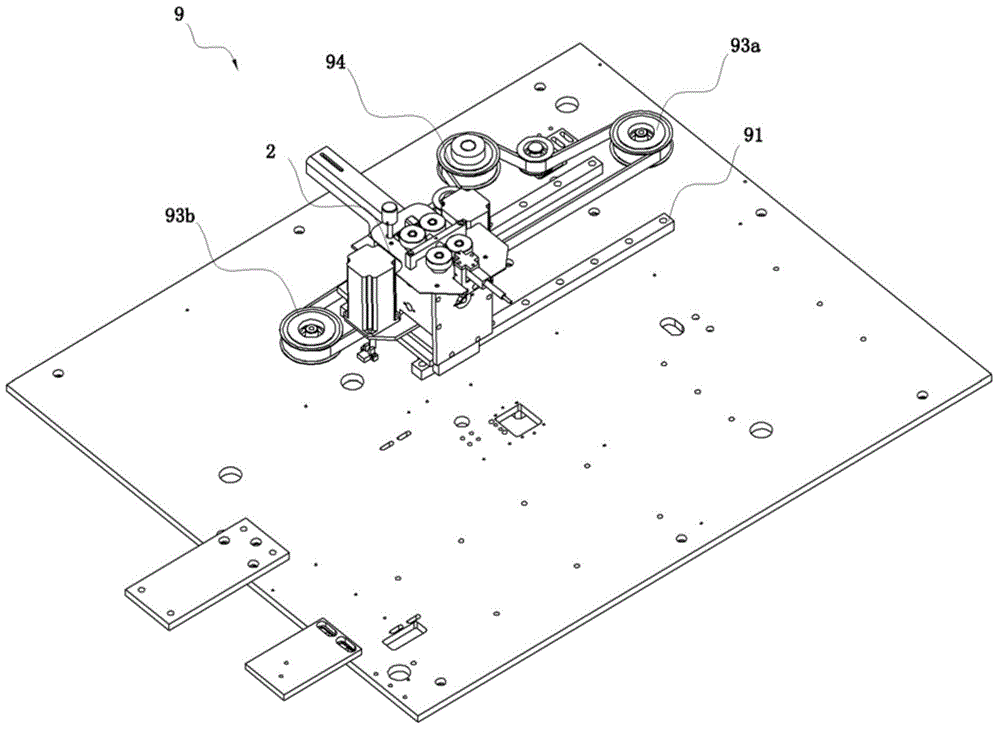

[0047] as attached figure 1 And attached figure 2 The full-automatic copper strip riveting terminal crimping terminal machine shown in the upper sheath has a working platform 100 and a wire feeding mechanism 2 installed on the working platform 100, a wire cutting and stripping device 3, a sheath feeding device 5, a second A terminal crimping device 1 , a clamping device 4 , a first belt transmission mechanism 9 and a copper strip riveting machine 6 .

[0048] The wire feeding mechanism 2 is used for conveying electric wires, and can advance or retreat the conveyed electric wires.

[0049] as attached Figure 5 And attached Image 6As shown, the wire feeding mechanism 2 includes a wire feeding frame 21, at least one pair of wire feeding wheels 22 and a wire feeding wheel seat 23 installed correspondingly to the wire feeding wheels 22, and the wire feeding frame 21 is provided with a wire feeding wheel Seat mounting shaft 24, the wire-feeding wheel seat 23 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com