Steel ball and steel segment sorter

A sorting machine and steel section technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of poor sorting effect, high work efficiency, low efficiency of screening steel sections or steel balls, etc., and achieve work efficiency. High, easy to operate, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

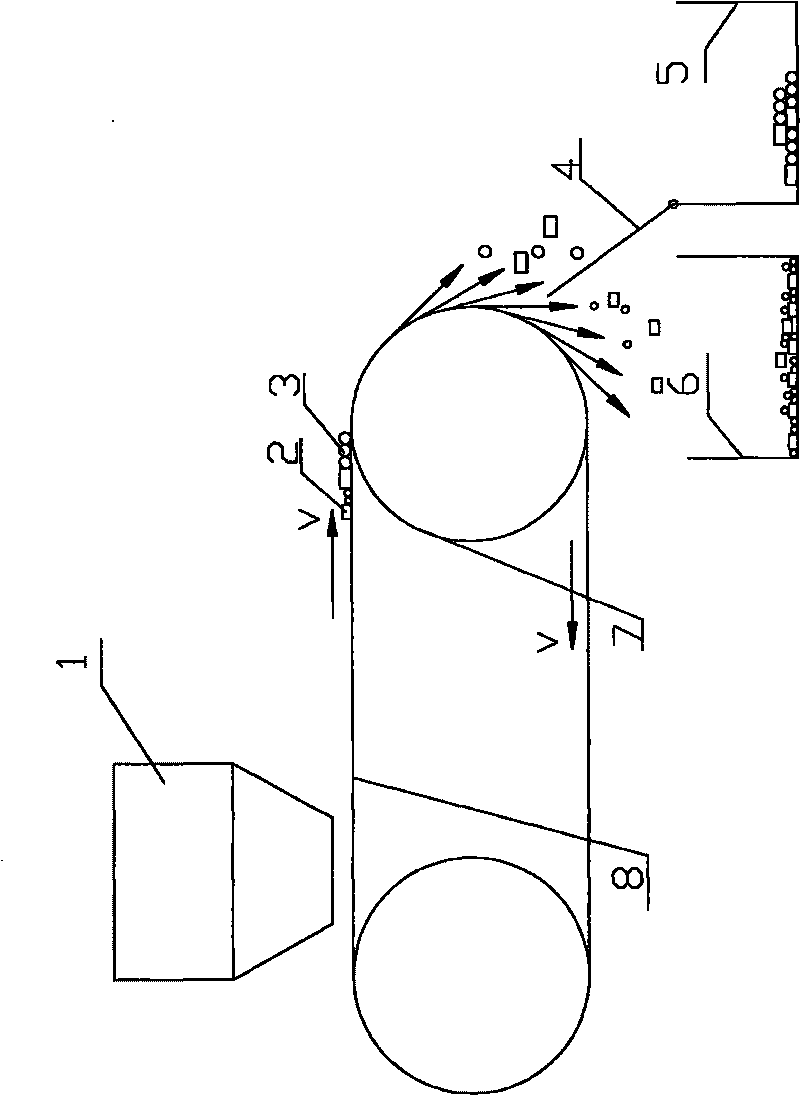

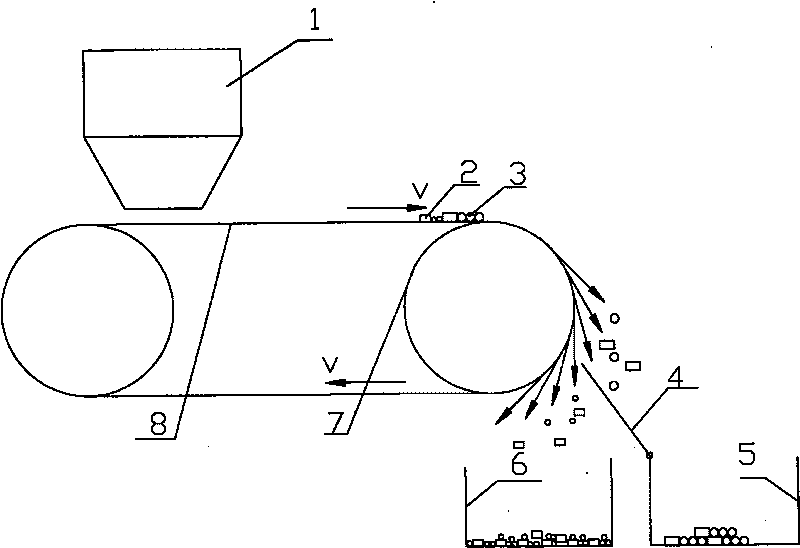

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Present embodiment is a kind of steel ball, steel section sorting machine, by belt conveyer, steel ball to be sorted, steel section receiving hopper, qualified product, waste product dividing plate, the finished product container of collecting steel ball, steel section and waste container etc.

[0010] See figure 1 , the driving drum or reversing drum of the belt conveyor is an electromagnetic drum 7, the conveyor belt 8 is set on the drum of the belt conveyor, and the top of the conveyor belt 8 is provided with a receiving hopper 1 for holding steel balls or steel sections to be sorted. The lower part of the receiving hopper 1 for sorting steel balls or steel sections is a cone structure, which is perpendicular to the conveyor belt 8, and the bottom of the cone is provided with a material leakage port. Within the range of the lower half drum of the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com