Self-moving belt machine tail part

A belt conveyor, self-moving technology, applied in conveyors, conveyor objects, cleaning devices, etc., can solve the problems of low degree of mechanization, high labor intensity and labor, and achieve the effect of solving adjustment difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

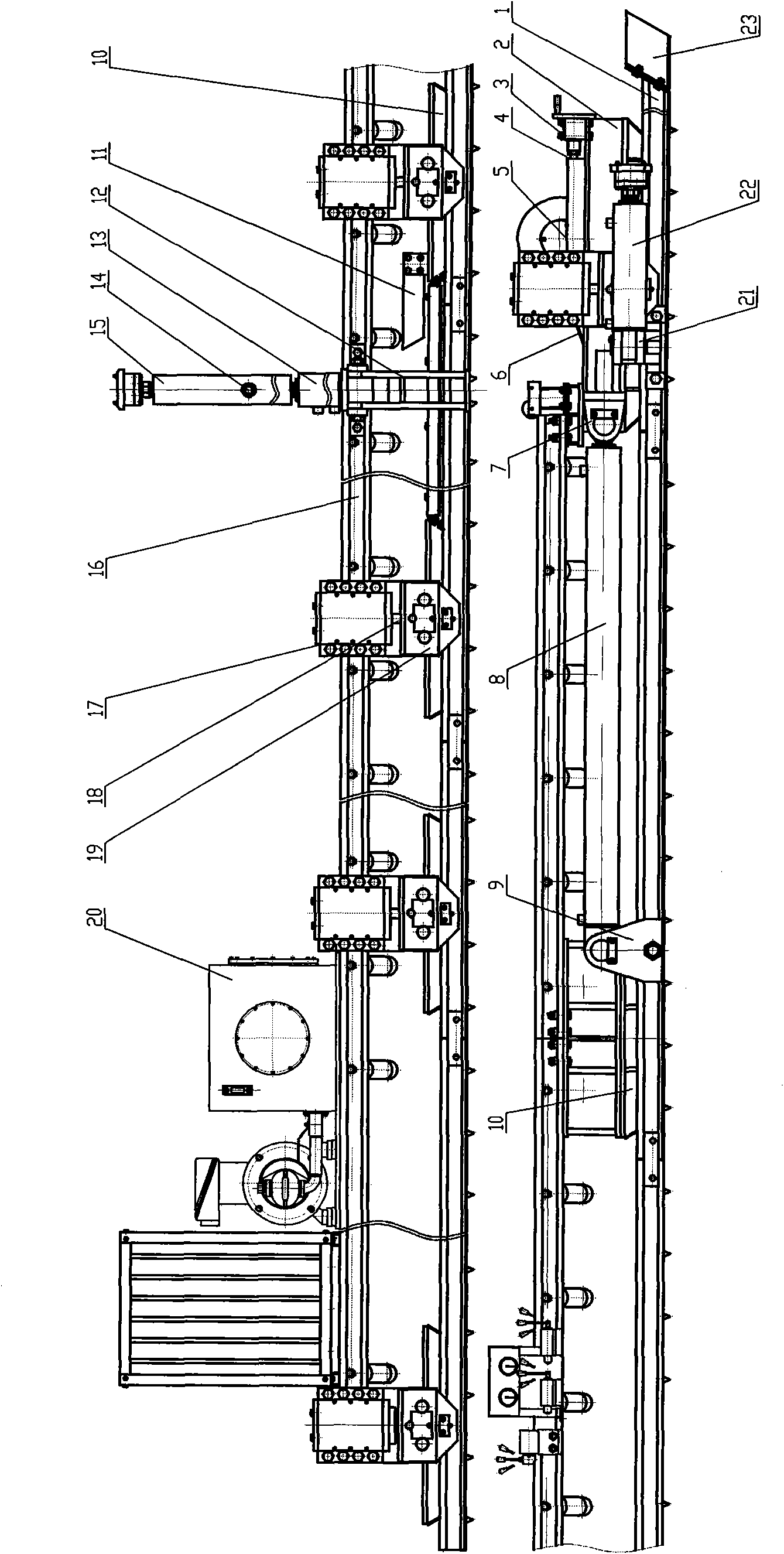

[0021] The present invention comprises machine tail 2, middle frame 10, upper travel guide rail 16, hydraulic system 20, also comprises lifting mechanism, pushing cylinder 8, lower travel guide rail 1, and lifting mechanism is composed of lifting cylinder 18 and support cylinder frame 17, two-way travel guide wheel frame 19, the tail 2 and the middle frame 10 are respectively equipped with a support cylinder frame 17, the two-way travel guide wheel frame 19 is installed on the lower travel guide rail 1, and the lifting cylinder 18 is connected to the support cylinder frame 17 and the two-way travel guide wheel frame 19 respectively, The following walking guide rail 1 is installed on the tail both sides of the machine, and the bottom surface has a floor to hold, and the oil cylinder 8 is installed between the following walking guide rail 1 and the machine tail. When moving, the machine tail can be raised and seated on the lower walking guide rail 1, and the machine tail is moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com