A high-pressure and high-speed damper precise adjustment mechanism

An adjustment mechanism, high-speed technology, applied in valve details, mechanical equipment, engine components, etc., to achieve high-precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with embodiment.

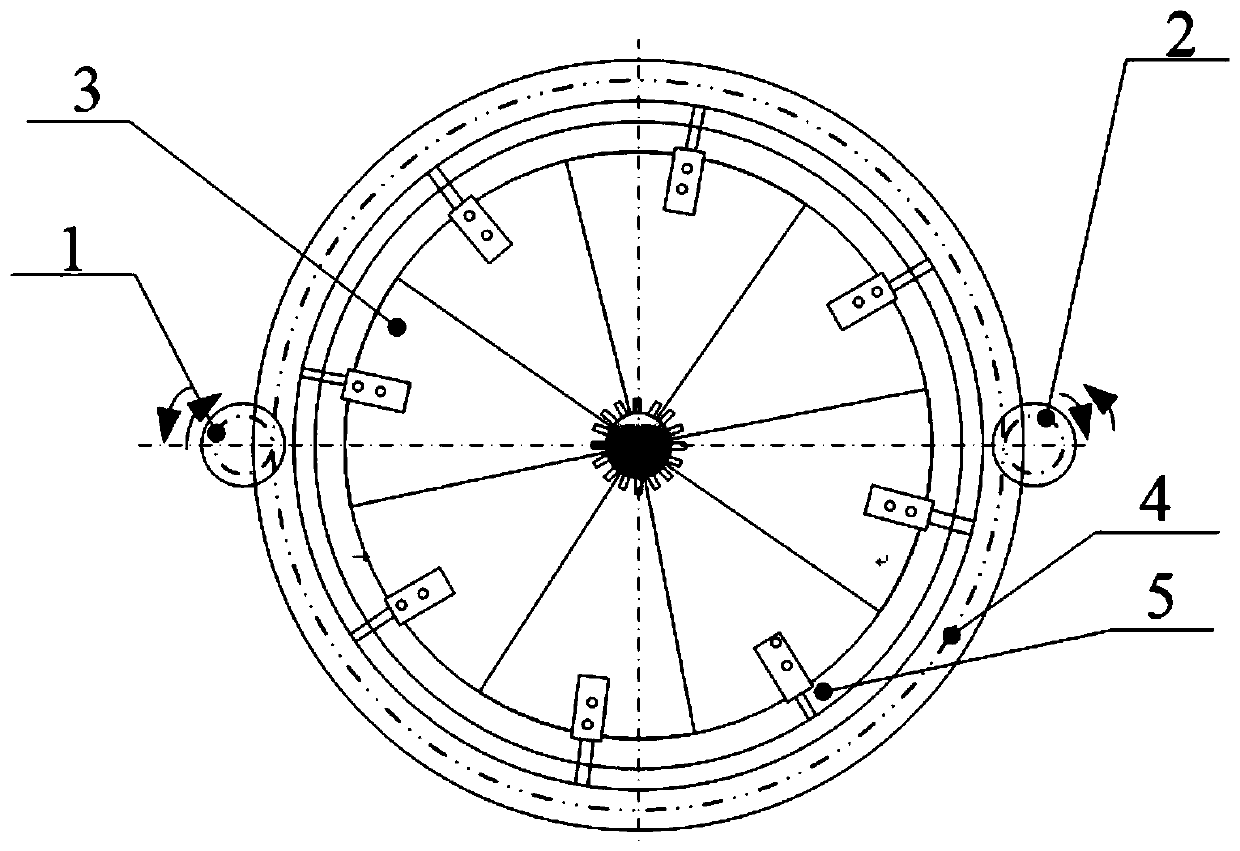

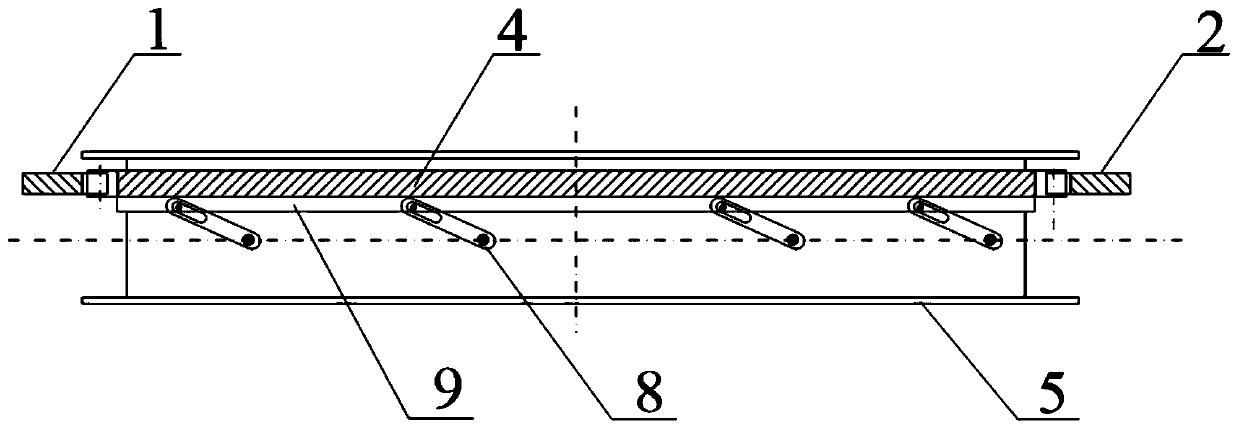

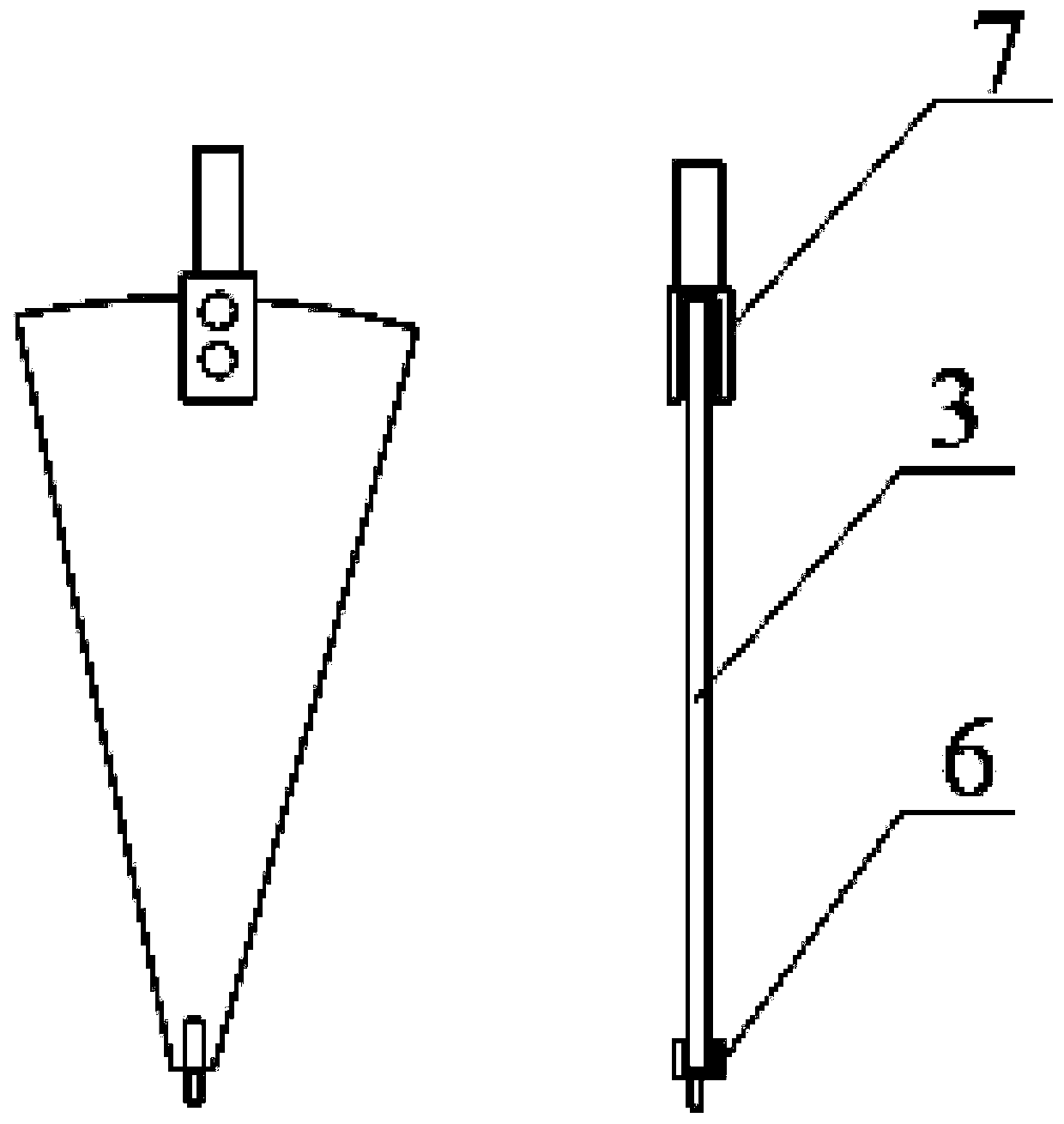

[0016] A high-pressure high-speed damper precision adjustment mechanism, including pinion A1, pinion B2, large gear ring 4, blade 3, fixed ring 5, transverse connecting rod 8, flange 9, connecting small shaft A6 and connecting small shaft B7.

[0017] The fixed ring 5 covers the large gear ring 4, and the outer side of the large gear ring 4 fixes the pinion A1 and the pinion B2 symmetrically along the diameter, and the two small gears mesh with the large gear ring 4 respectively. The motor drives the large gear ring 4 to rotate; the large gear ring 4 and the flange 9 are fixed together, the flange 9 is located on the outer wall of the fixed ring 5, the large gear ring 4 drives the flange 9 to rotate, and the flange There are 2N protrusions on the outer side of 9, and the protrusions are connected with the oval hole of the transverse connecting rod 8; one end of the transverse connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com