Machining process of protective ring for traction motor

A technology of mechanical processing and traction motor, which is applied in the field of rail transit, can solve problems such as poor shape accuracy, high processing difficulty, and poor dimensional accuracy, and achieve the effect of reducing workpiece deformation and machining stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] A machining process of a retaining ring for a traction motor in this embodiment, the process includes the following steps:

[0035] (1) Rough turning: Take a ring blank, rough turn the outer circle, inner hole and end face, leave a margin of 1.5mm on one side, and leave a margin of 1.5mm on one side for the thickness, and strictly control the size of the inner hole and outer circle;

[0036] (2) Semi-finishing the outer circle: take a ring-shaped claw, pass the ring-shaped claw to clamp the inner hole of the blank, and turn the outer circle on the flat end surface, leaving a margin of 0.5mm on one side. The roundness of the outer circle is controlled within 0.1mm;

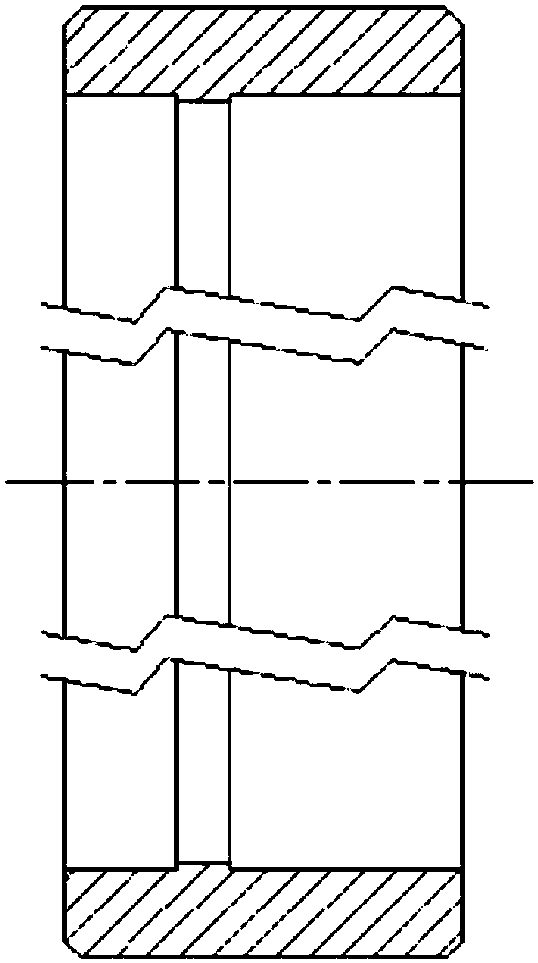

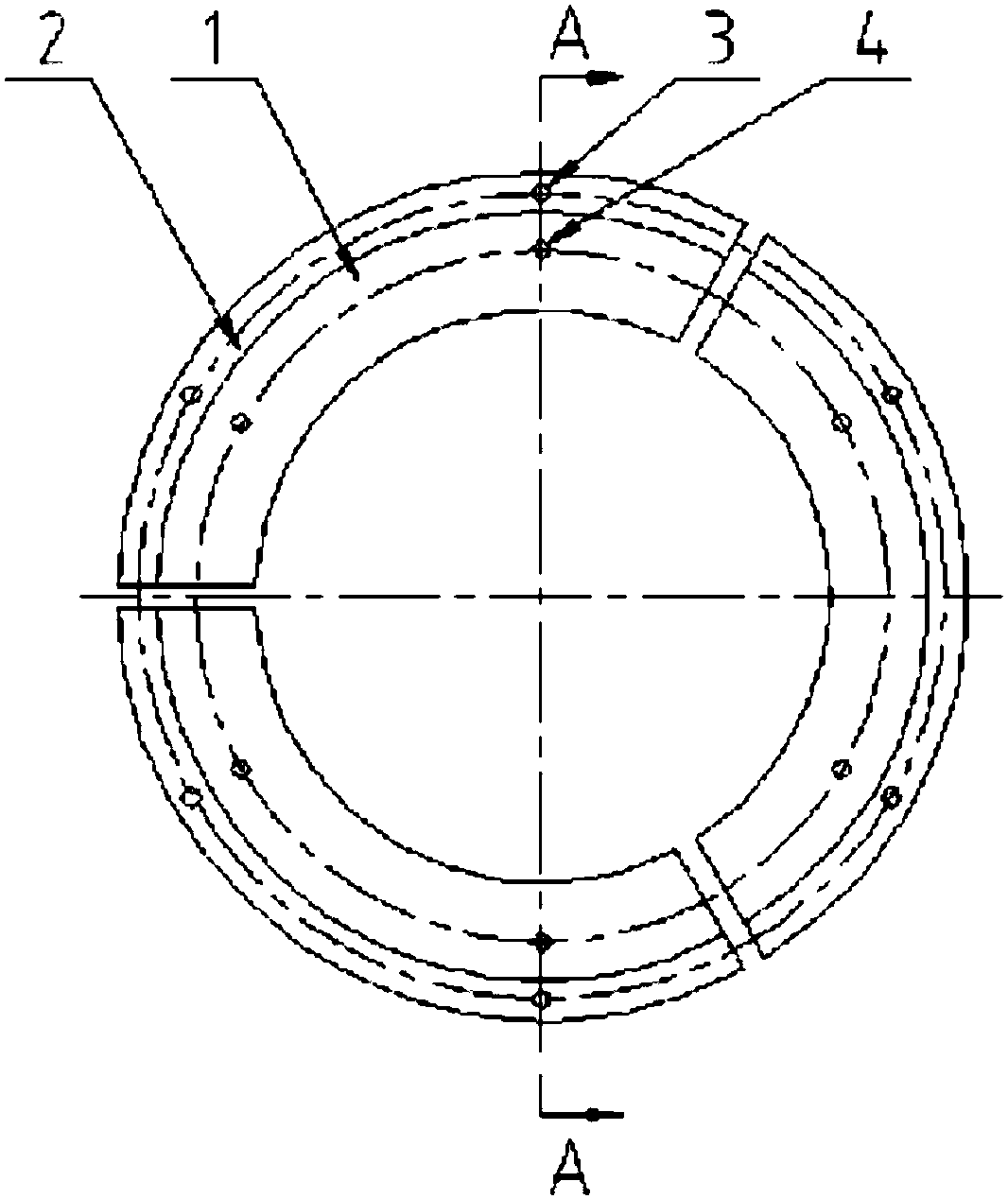

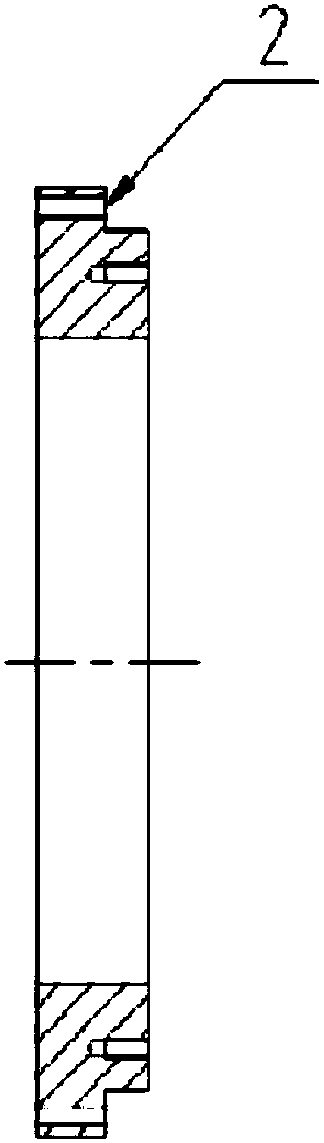

[0037] Such as figure 2 , image 3 As shown, the annular claw includes three arc-shaped clamping blocks 1 arranged in a ring, and the outer side of the arc-shaped clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com