Material continuous dynamic metering device

A dynamic measurement and material technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as measurement errors, uneven materials, unstable material belts, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

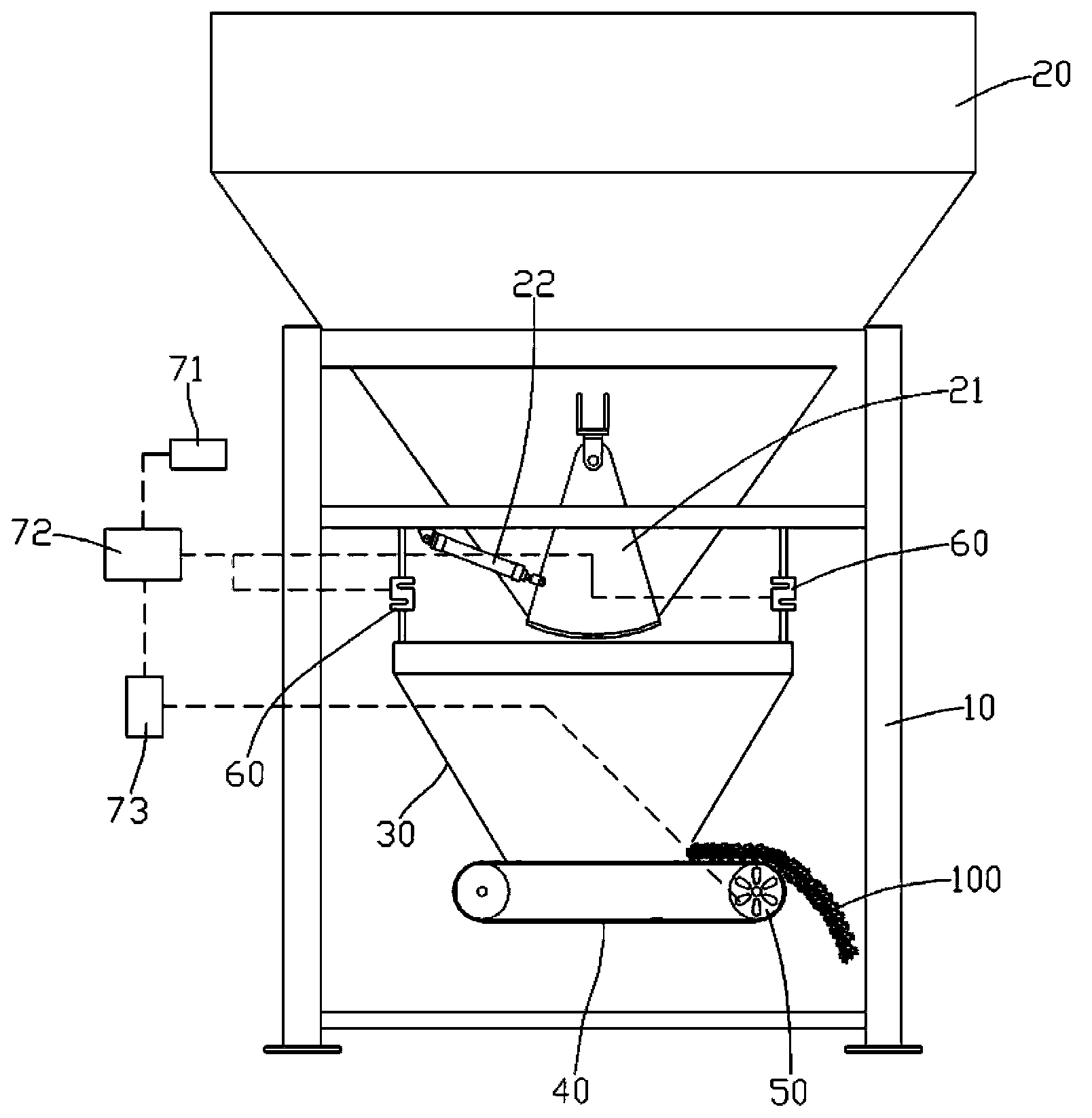

[0017] See figure 1 Shown: the material continuous dynamic metering device of the present invention comprises frame (10), storage hopper 20, metering hopper 30 and conveyor belt conveyor 40, wherein, storage hopper 20 is positioned at the top of metering hopper 30, and its lower part is provided with by cylinder 22 The material door 21 that controls the opening and closing, the storage hopper 20 and the conveyor belt conveyor 40 driven by the frequency conversion motor 50 are connected as a whole, and are freely suspended on the frame 10 through 3~4 load cells 60. The weight controller 72 is connected, and the weighing controller 72 is connected with the electromagnetic reversing valve 71 which controls the opening and closing of the material door 21 through the cylinder 22 and the frequency conversion controller 73 which regulates the speed of the frequency conversion motor 50 .

[0018] When the material continuous dynamic metering device of the present invention works, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com