Full-automatic solar battery piece welding belt machine

A solar cell, fully automatic technology, applied in the direction of circuits, electrical components, welding equipment, etc., can solve the problems of resource consumption, poor quality of cells, cumbersome steps, etc., and achieve the effect of cost saving and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

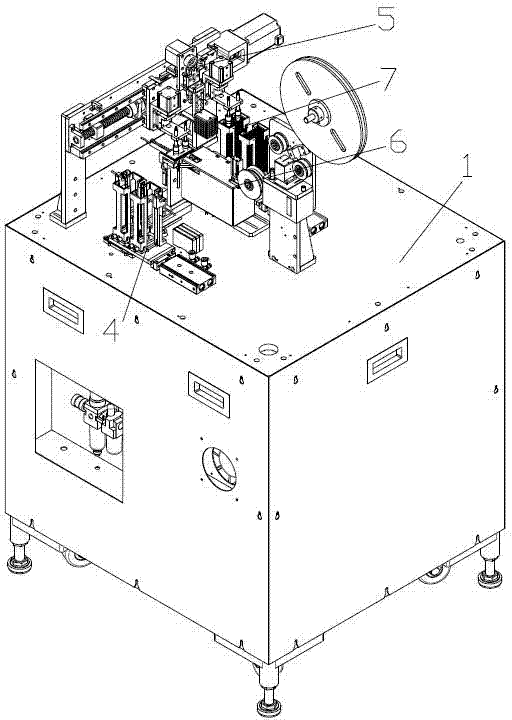

[0039] A fully automatic solar cell strip welding machine, mainly including a welding strip system, a working frame 1 and a control system 3, the working frame 1 is a sheet metal frame composed of a workbench and a work cabinet, and is provided with The frame cover 2 adapted to it, the control system is a man-machine combination programmable control system, and the welding ribbon system mainly includes an automatic material feeding system 4, a conveying material system 5, a welding ribbon conveying system 6 and an automatic receiving mechanism 7; The ribbon conveying system 6 is installed in the middle of the workbench of the working frame, the conveying material sheet system 5 is installed on one side of the workbench, and the automatic feeding sheet system 4 is installed on the other side adjacent to the conveying material sheet system 5 side;

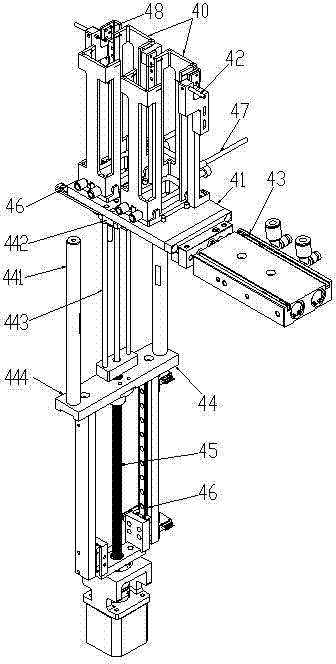

[0040] The automatic feeding system 4 is mainly composed of an automatic feeding mechanism and a feeding box 40. The automatic feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com