Simple earth dumping machine

A soil dumper, a simple technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of complex structure, short manufacturing cycle, long manufacturing cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

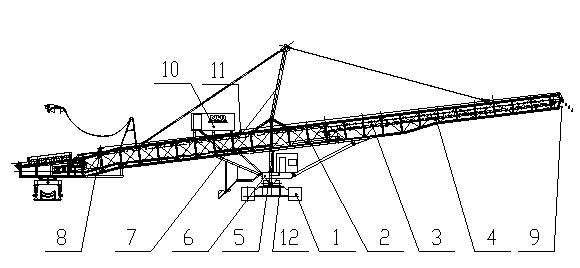

[0009] Referring to the accompanying drawings, a simple soil dumper consists of a crawler walking device 1, an arm frame device 2, a belt conveyor 3, a telescopic trolley 4, a bracket device 5, a rotary device 6, a pull rod device 7, a winch device 8, and a walking platform railing. 9. Driver's cab 10, cable wiring system 11, and centralized lubrication system 12. The simple dumper has only one truss-type boom device 2, the discharge belt conveyor 3 is placed inside the boom device 2, and the telescopic trolley 4 is placed on the boom Inside the device 2, the middle position of the discharge arm frame of the soil dumper is connected with the crawler belt traveling device 1 through the bracket device 5 and the slewing device 6; Arranged in the middle and upper part of the boom device 2; the walking platform railing 9 and the cable wiring system 11 are arranged along the length direction of the boom device; the centralized lubrication system 12 is arranged at the rear of the craw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com