Method for producing metallized pellets by using composite carbon-containing pellets and chain belt type roasting machine

A technology of metallized pellets and roaster, applied in the field of metallized pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

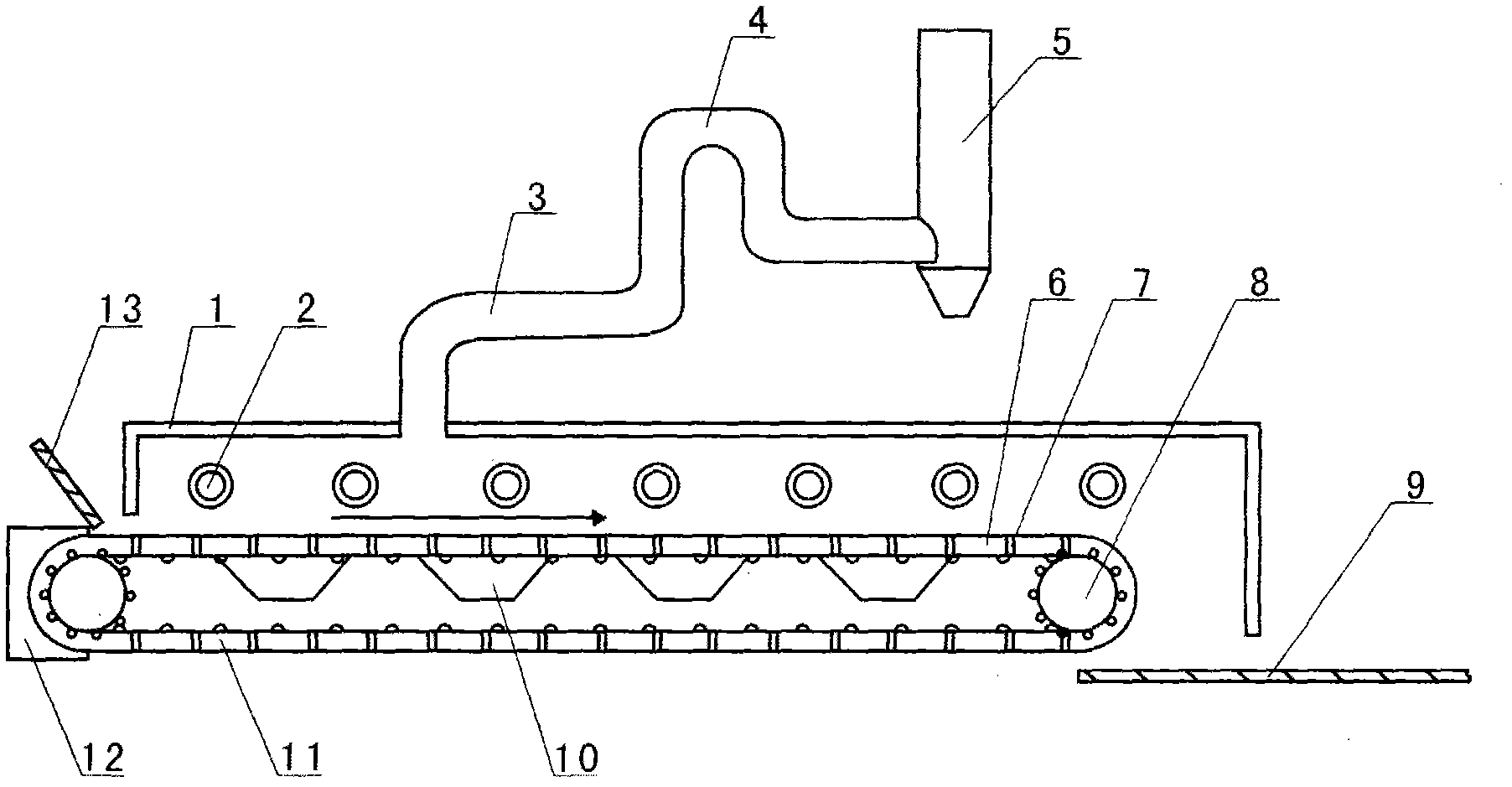

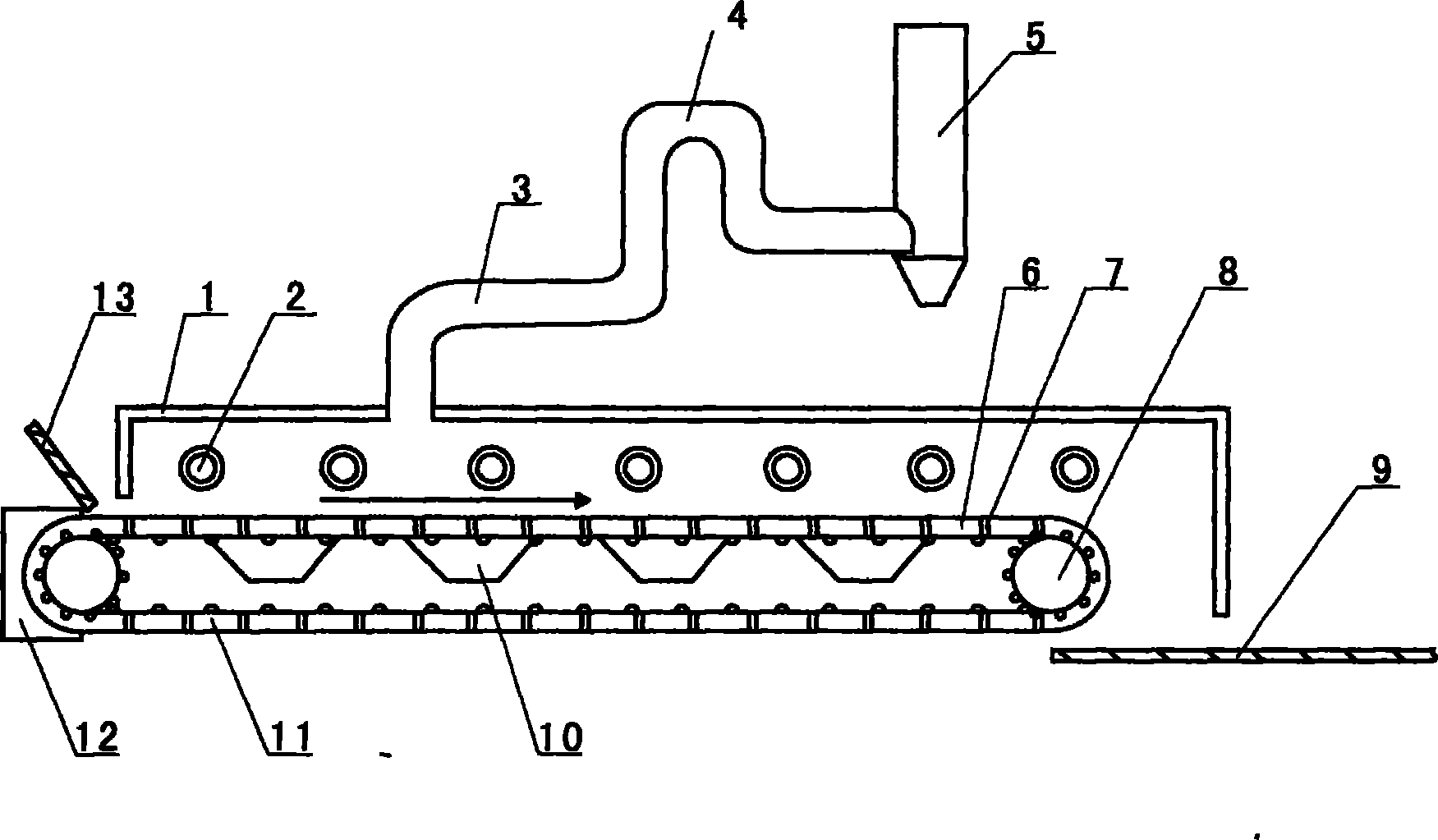

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0039] like figure 1 As shown, the chain-belt roaster of the present invention includes a body of furnace 1, a chain-belt machine, a shuttle-type distributing machine 13, a scale plate discharge machine 9 and an air supply chamber 10, and the chain-belt machine includes a chain belt 11, a chain The pulley 8 and the driving device 12, the chain belt 11 is formed by connecting the chain plate 6 through the pin shaft 7, the driving device 12 generally adopts a frequency conversion motor, and its output power drives the chain pulley 8 or the chain belt 11, so that the chain belt 11 winds the chain The pulley 8 rotates; the two ends of the furnace body 1 are respectively provided with a feed port and a discharge port (not marked in the figure), the upper part of the furnace body 1 is provided with a chimney 3, and the top of the chimney 3 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com