System for researching material distribution rule of furnace top equipment

A technology of furnace top equipment and material distribution, which is applied in the field of ironmaking, can solve the problems of poor universality of conclusions, insufficient research, single simulation method, etc., and achieve the effect of simple experimental plan and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

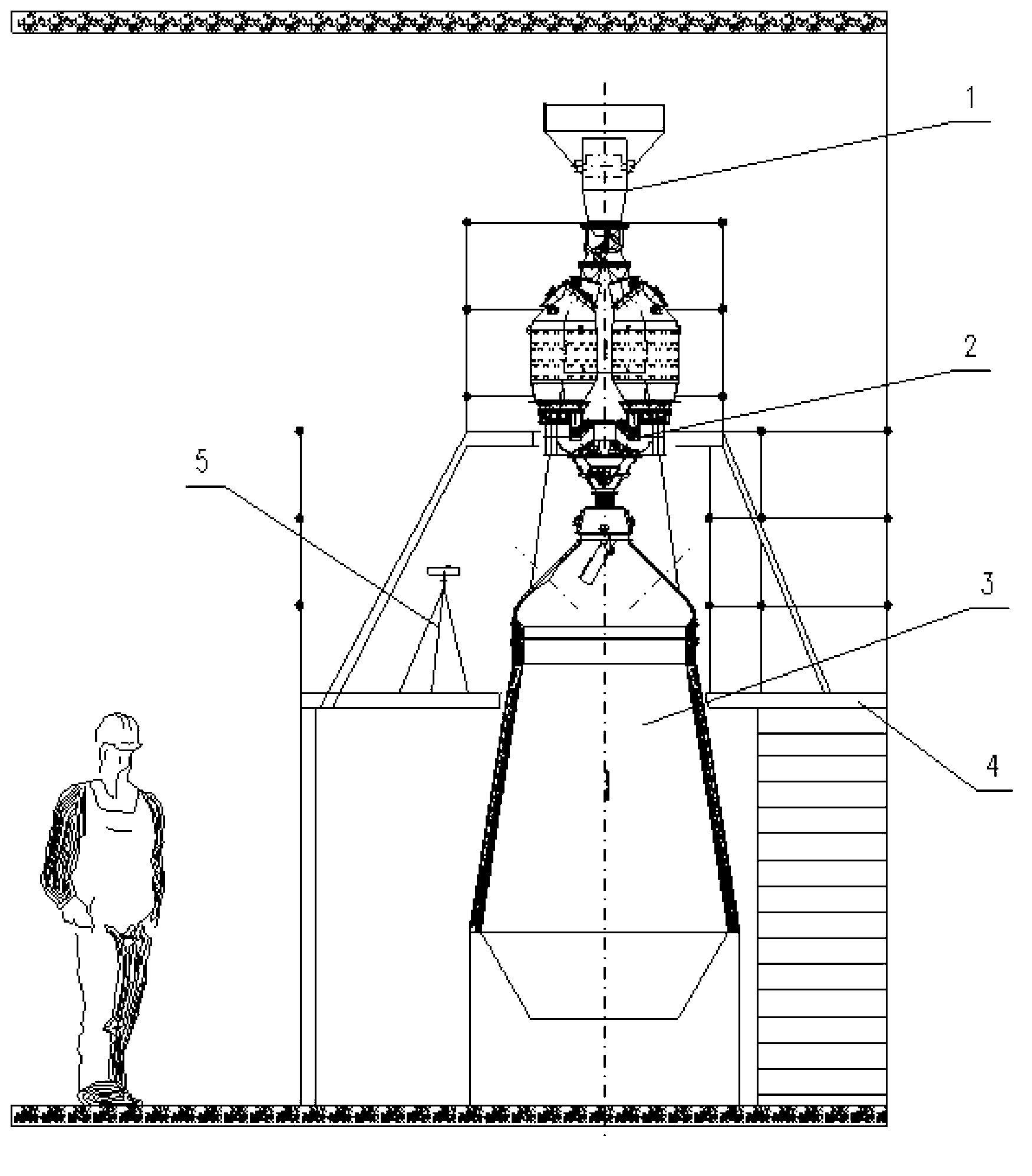

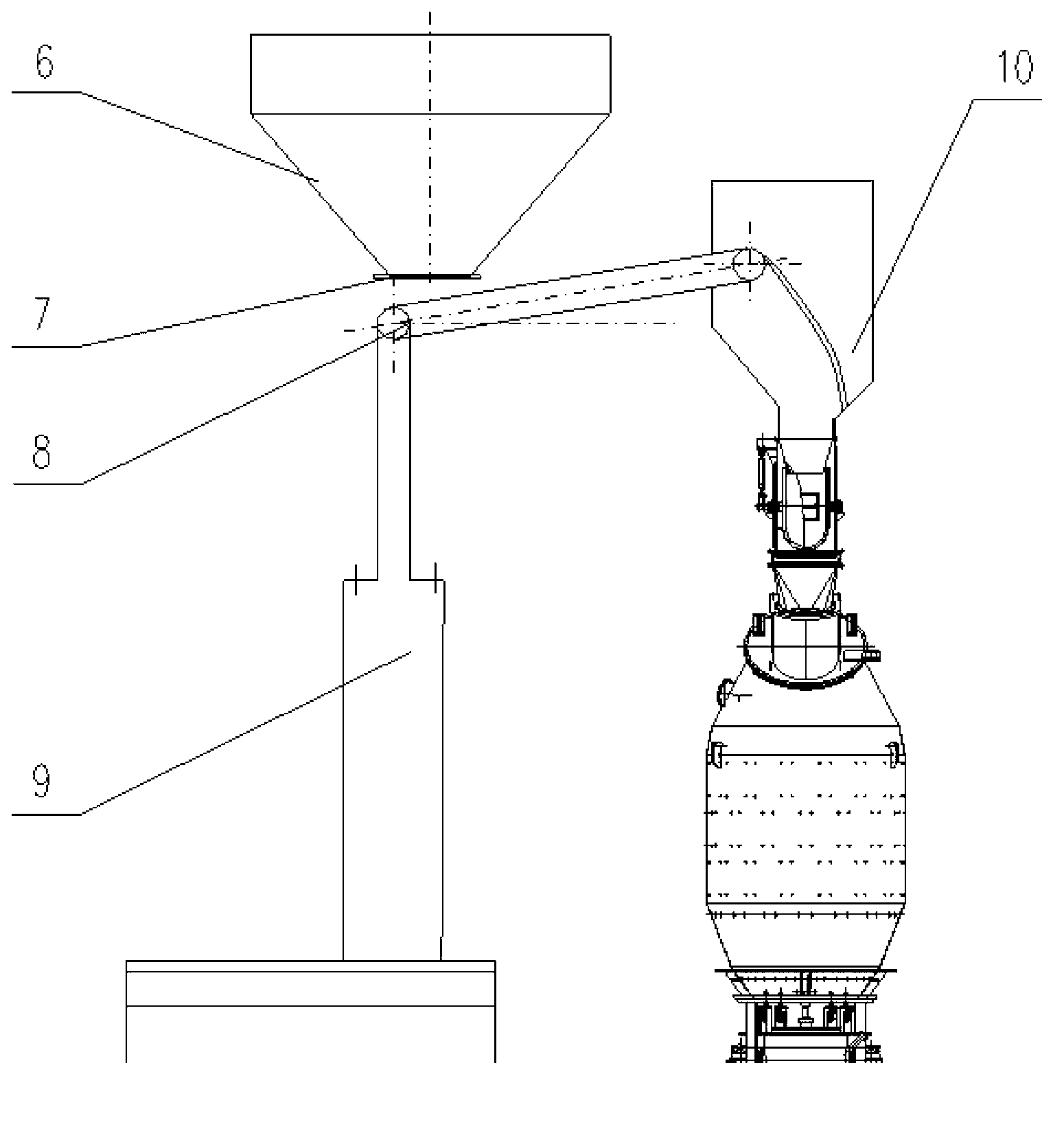

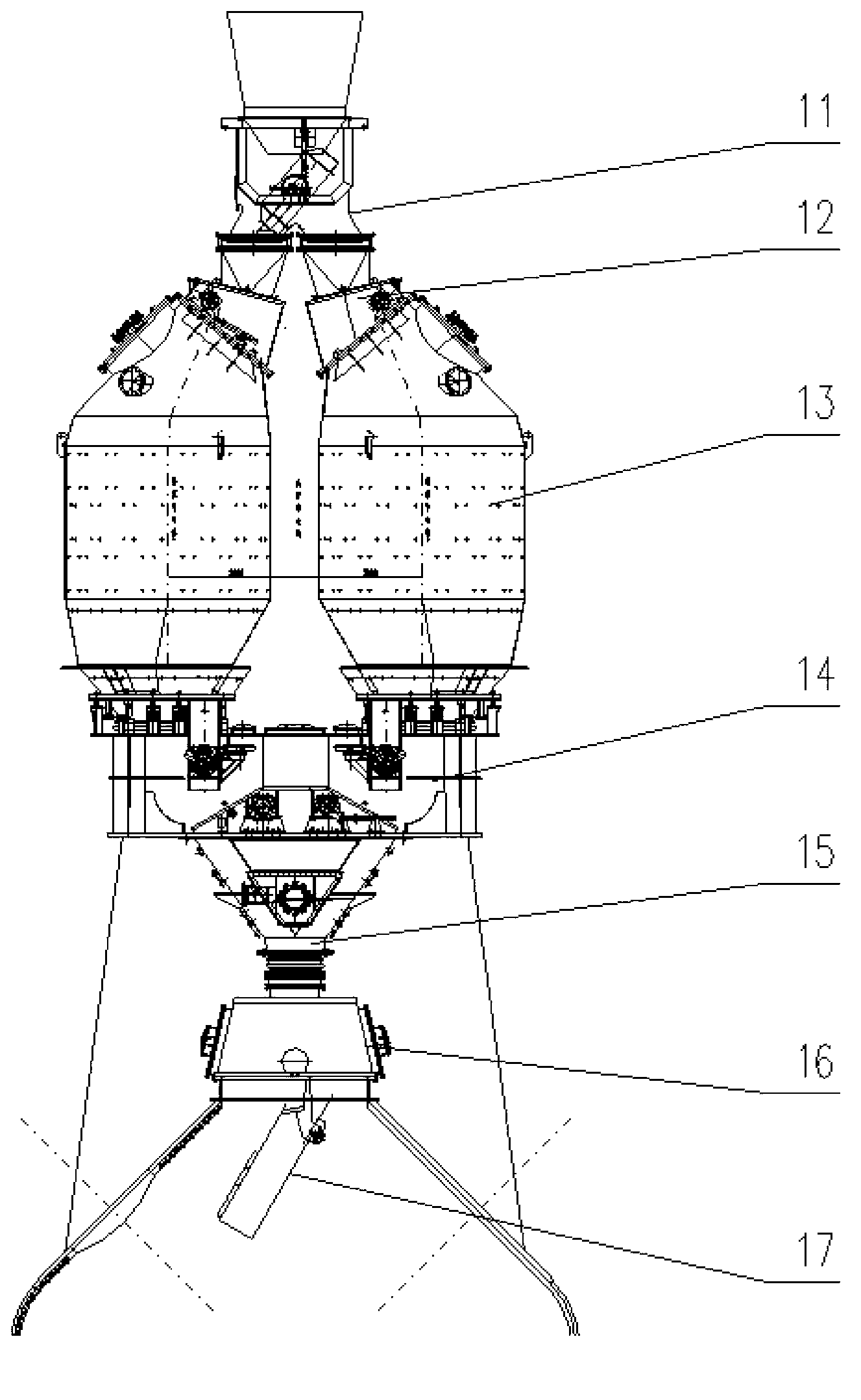

[0039] The present invention includes a fully simulated belt conveyor feeding system 1, a fully transparent furnace top material distribution equipment overall model 2, a fully transparent furnace body partition research model 3, an enterprise-level high-speed camera analysis system 5, and an experimental platform (two floors) 4. The fully simulated belt conveyor feeding system 1 is at the top of the whole system, connected with the second platform of the experimental platform 4 by a movable bracket, and its lower opening is connected with the overall model 2 of the fully transparent furnace top distribution equipment. The lower end of the overall model 2 of the fully transparent furnace top distribution equipment is installed on the fully transparent furnace body partition research model 3 . The shooting terminal of the enterprise-level high-speed camera analysis system 5 is generally placed on the first-floor platform of the experimental platform 4, and its position can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com