Offshore wind power single pile foundation horizontal bearing capacity test reaction device and its construction method

A technology of horizontal bearing capacity and single pile foundation, which is applied in foundation structure test, foundation structure engineering, construction, etc., can solve the problems that cannot meet the test reaction force of large-diameter piles, and achieve shortened test time, low requirements and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

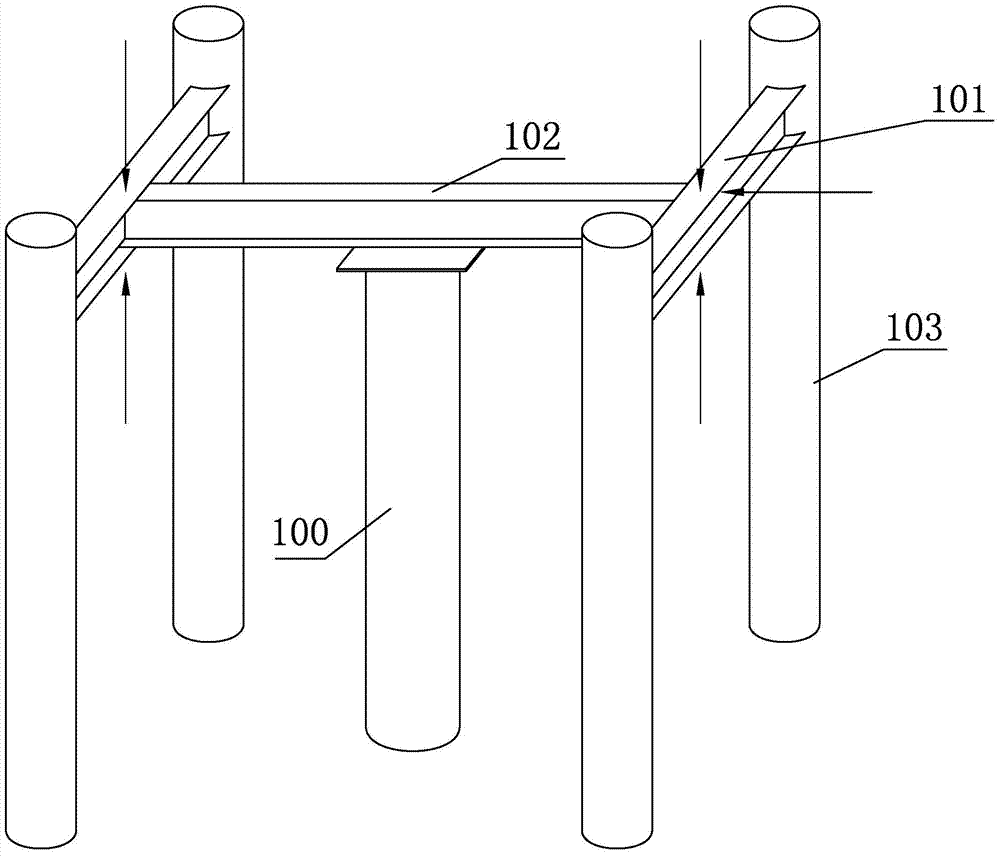

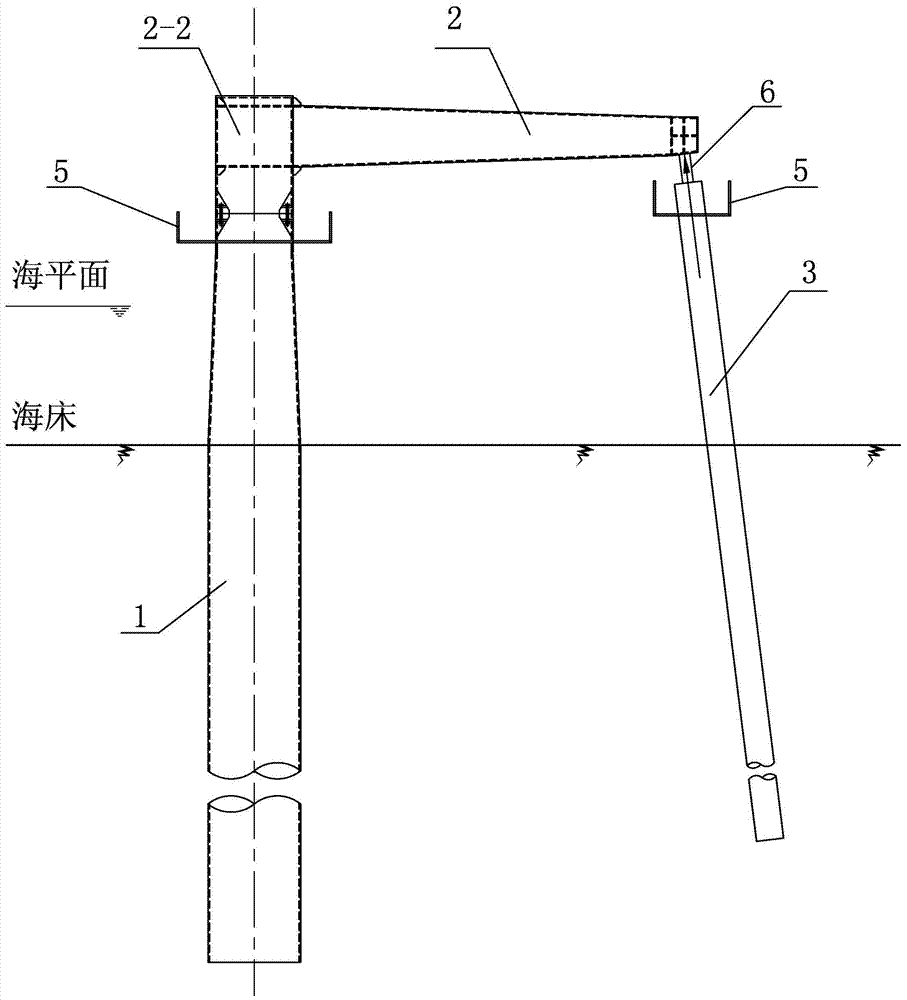

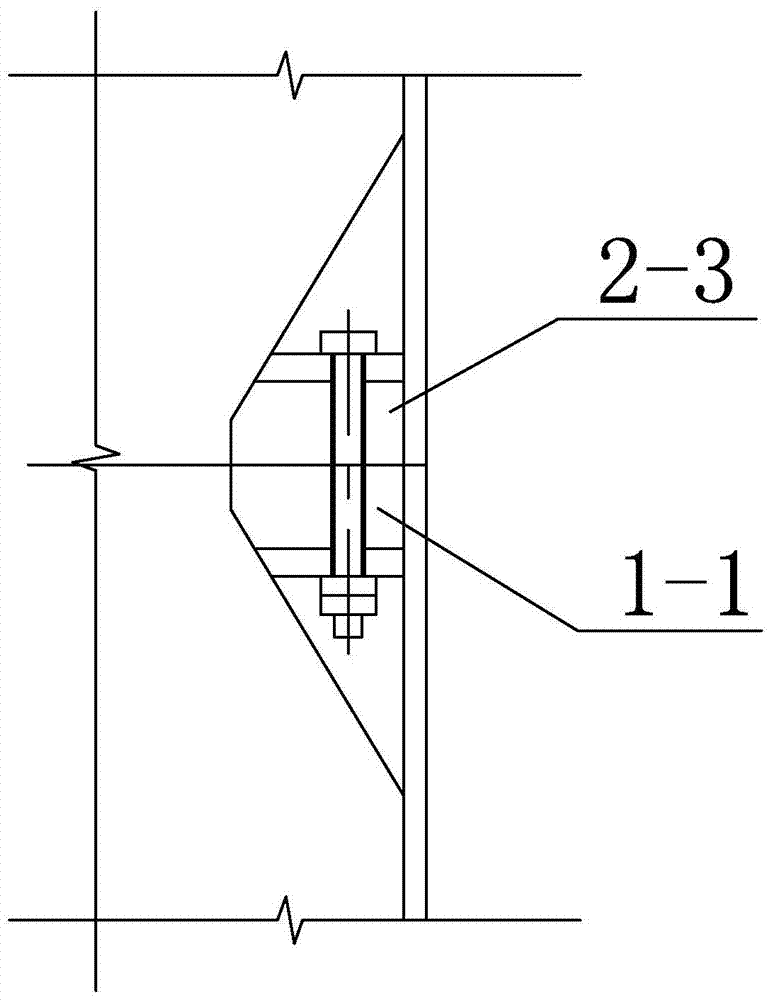

[0024] This embodiment is an offshore wind power single pile foundation horizontal bearing capacity test reaction device and its construction method, such as figure 2 As shown, the device includes a test pile 1 driven into the seabed surface to the bearing layer to obtain good stability, and a reaction pile 3 is driven obliquely near the test pile 1, and the test pile 1 and the reaction pile The steel box girder assembly 2 is horizontally installed between the upper ends of the 3, and the operating platform 5 is installed on the top of the test pile 1 and the reaction pile 3, the steel box girder assembly 2 and the hydraulic jack system installed on the top of the reaction pile 3 6 jacks contact and tighten. Among them, the top of the test pile 1 is connected with a lower flange 1-1, and the operating platform 5 is set under the lower flange 1-1; the steel box girder assembly 2 is composed of a horizontal beam 2-1, a vertical anchorage section 2-2 and an upper The flange 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com