Automatic production device for threshold member of electric vehicle

A production device and threshold technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of labor resources and production space waste, product quality is difficult to guarantee, workpiece bumping, extrusion, etc., to reduce labor resources and Waste of production space, strong versatility, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

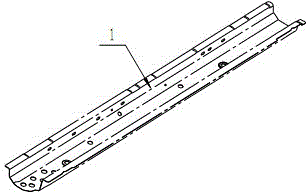

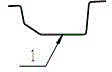

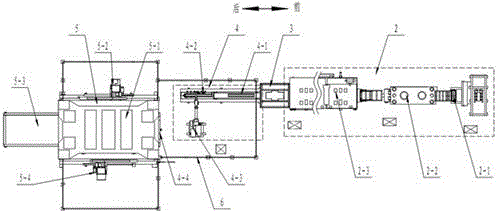

[0024] see image 3 , Figure 4 , the present invention includes a roll forming unit 2, a cutting mechanism 3, a workpiece conveying unit 4, a stamping unit 5 and a guardrail 6, the cutting mechanism 3 is arranged between the roll forming unit 2 and the workpiece conveying unit 4, and the workpiece Conveyor unit 4 is made up of transition material receiving belt conveyor 4-1, fast moving positioning mechanism 4-2, handling manipulator 4-3 and stamping unit loading workbench 4-4, and one end of described transition material receiving belt conveyor 4-1 is connected to The discharge end of the cutting mechanism 3 is docked, and the other end is docked with the fast-moving positioning mechanism 4-2, and the handling manipulator 4-3 is arranged between the fast-moving positioning mechanism 4-2 and the punching unit feeding table 4-4, The stamping unit feeding workbench 4-4 is matched with the stamping unit 5, and the workpiece is accurately centered and positioned through the stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com