Continuous steel belt punching production line

A production line and steel strip technology, applied in the field of stamping production lines, can solve the problems of low production efficiency, difficulty in ensuring hole and hole position accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

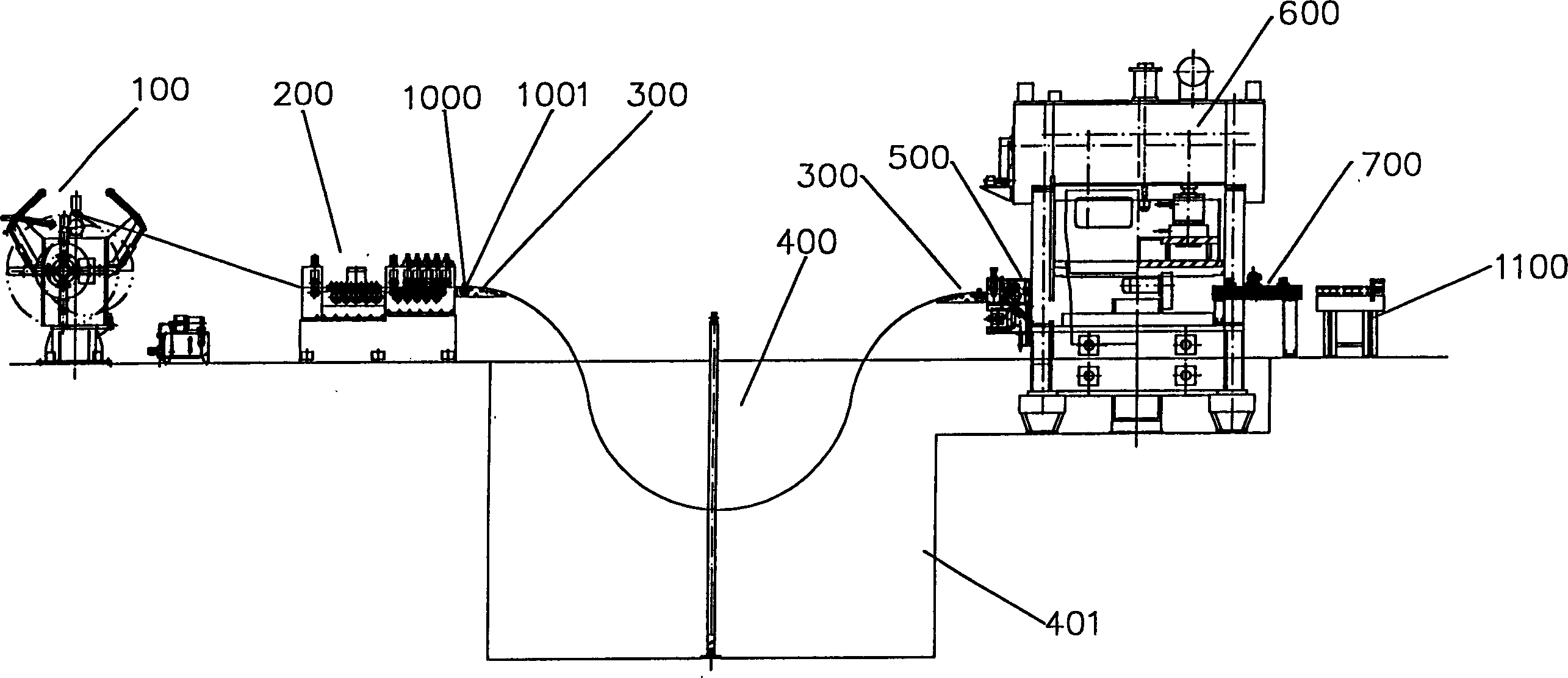

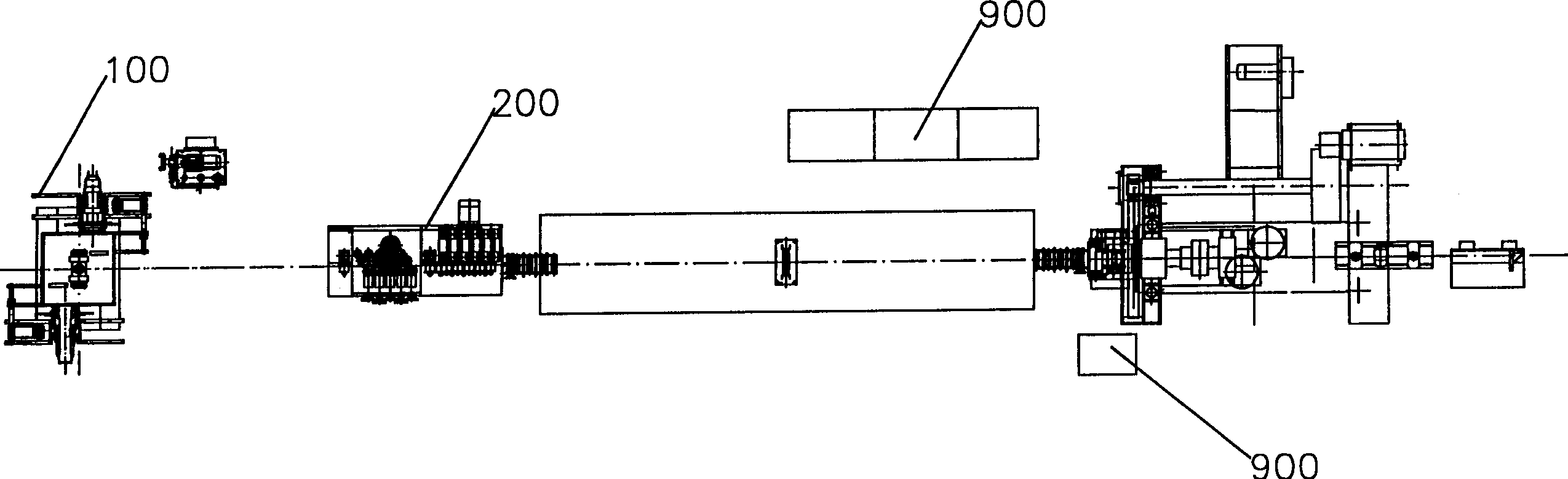

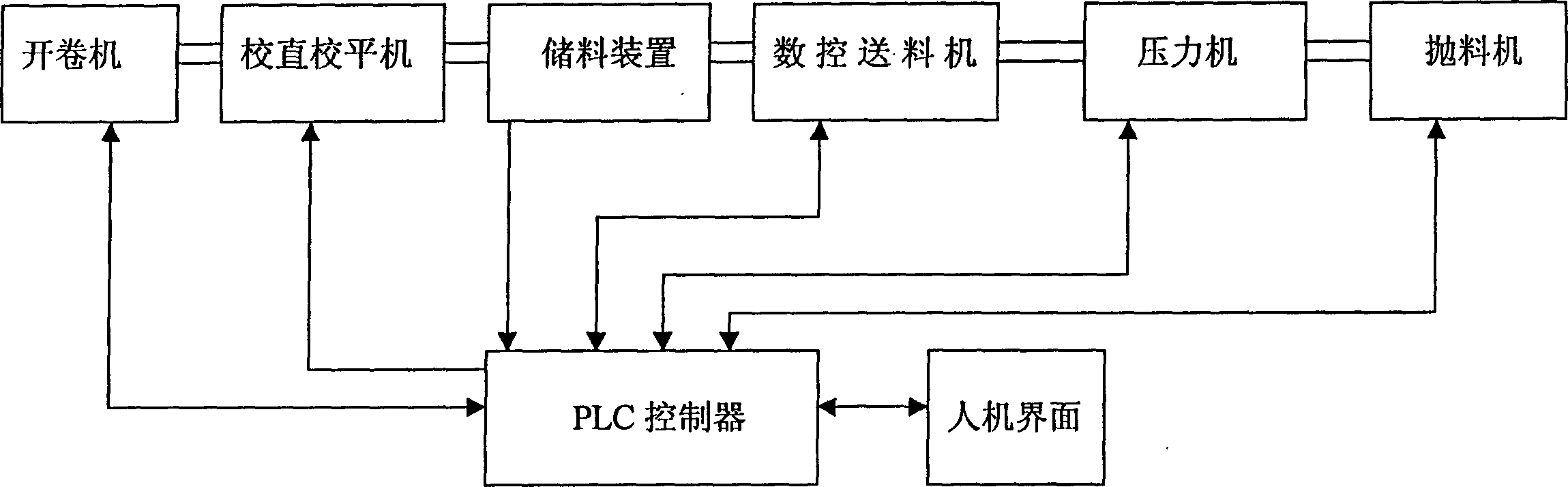

[0062] See Figure 1A , 1B , the figure shows a production line for continuous stamping of steel strip according to the present invention, which includes sequentially arranged: an uncoiler 100 for uncoiled steel strip, for straightening and straightening the steel strip after opening Straightening machine 200, the material storage device 400 arranged at the back of the straightening and leveling machine 200 is used to store enough belt material for the next step of feeding. On the feed side of the final press 600, the press 600 used for stamping steel strip forming, the throwing device 700 for throwing the processed workpiece is fixed on the discharge side of the press, and the throwing device is followed by the arrangement The material receiving device 1100, the production line also includes an electrical control device 900 that controls the servo feeding of the production line and continuous punching; the tail detection device 1000 is further provided on the adjustment brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com