System and method for quickly replacing electric bus batteries

A technology for quick replacement of electric buses and batteries, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of large footprint and complex structure, and achieve the effects of high positioning accuracy, accurate position, and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

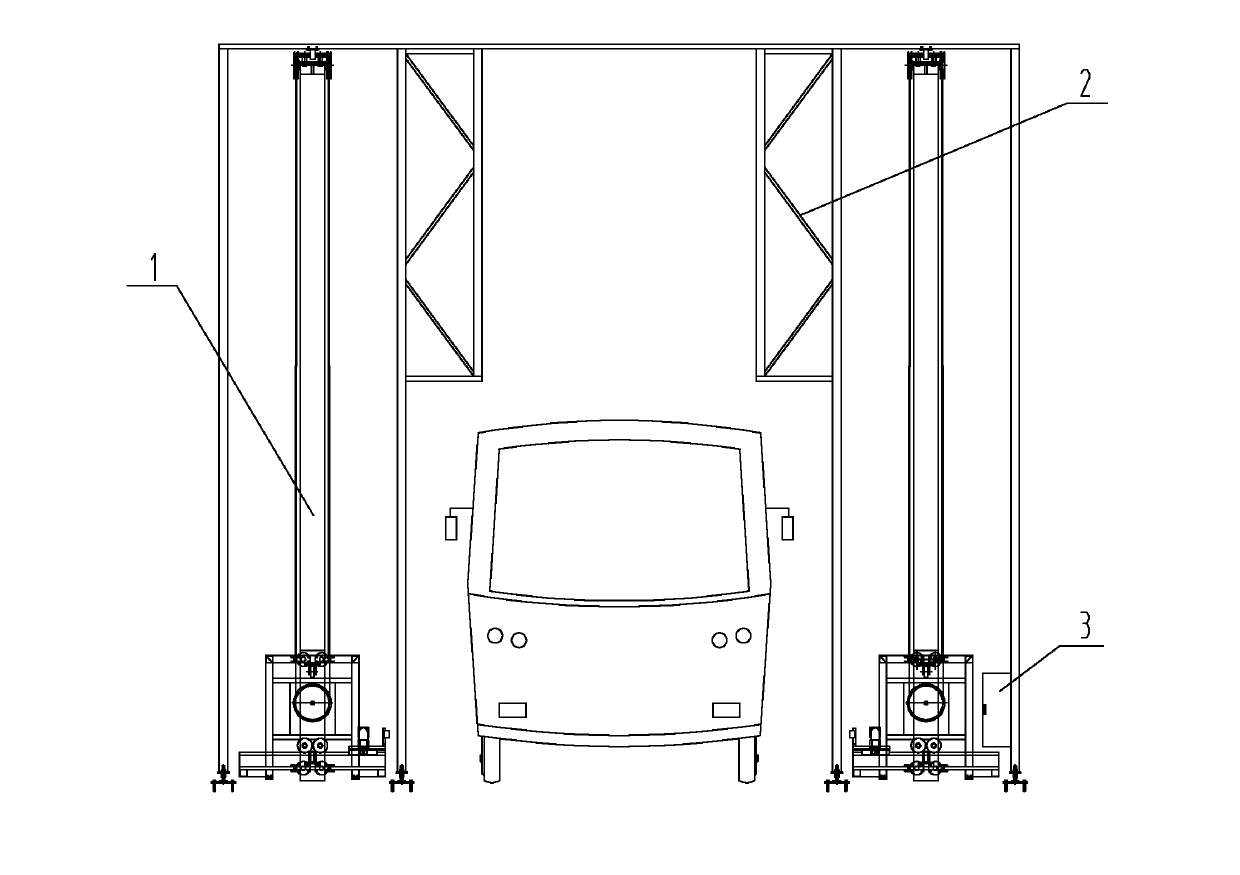

[0043] Such as figure 1 As shown, it includes a charging shelf unit 2 with a rechargeable battery placed on the upper part, and at least one elevating battery exchange robot 1 is arranged on the same side as the charging shelf unit 2, and the elevating battery exchange robot 1 is along the length of the charging shelf unit 2. Direction movement; Lifting battery replacement robot 1 removes the battery to be replaced from the electric bus, lifts it to the battery storage place on the upper part of the charging shelf unit, replaces the battery to be replaced, takes the charged battery and then falls to the battery Change the location to complete the battery replacement of the electric bus.

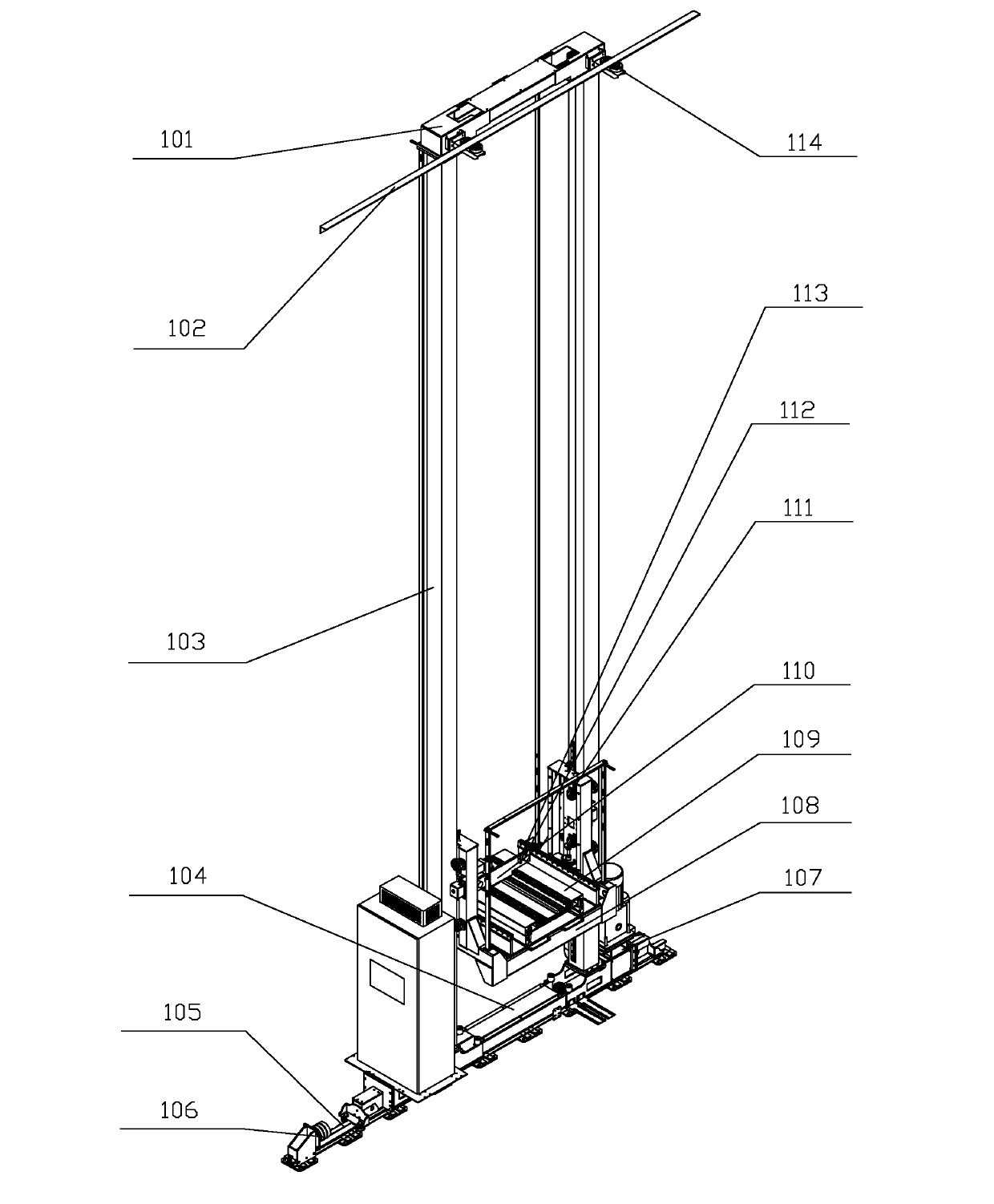

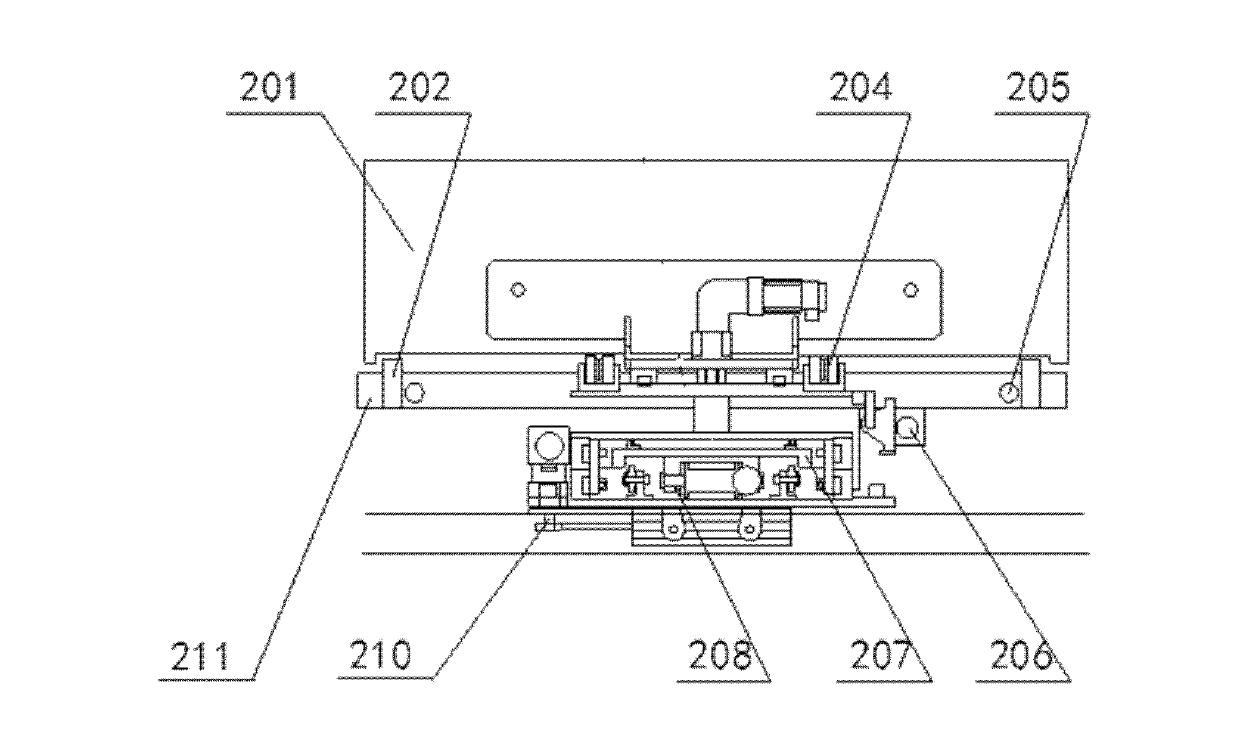

[0044] figure 2 , image 3 The figure shows the schematic diagram of the rear view structure of the battery exchange robot and the loading platform unit of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com