Well drilling tool mud scraping device

A drilling tool and drilling technology, used in cleaning tools, earthwork drilling, wellbore/well components, etc., can solve the problems of increasing difficulty and complexity, reducing mud scraping effect of drill pipe, and reducing work reliability, etc. Effectiveness and reliability, saving labor time, improving the effect of mud scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

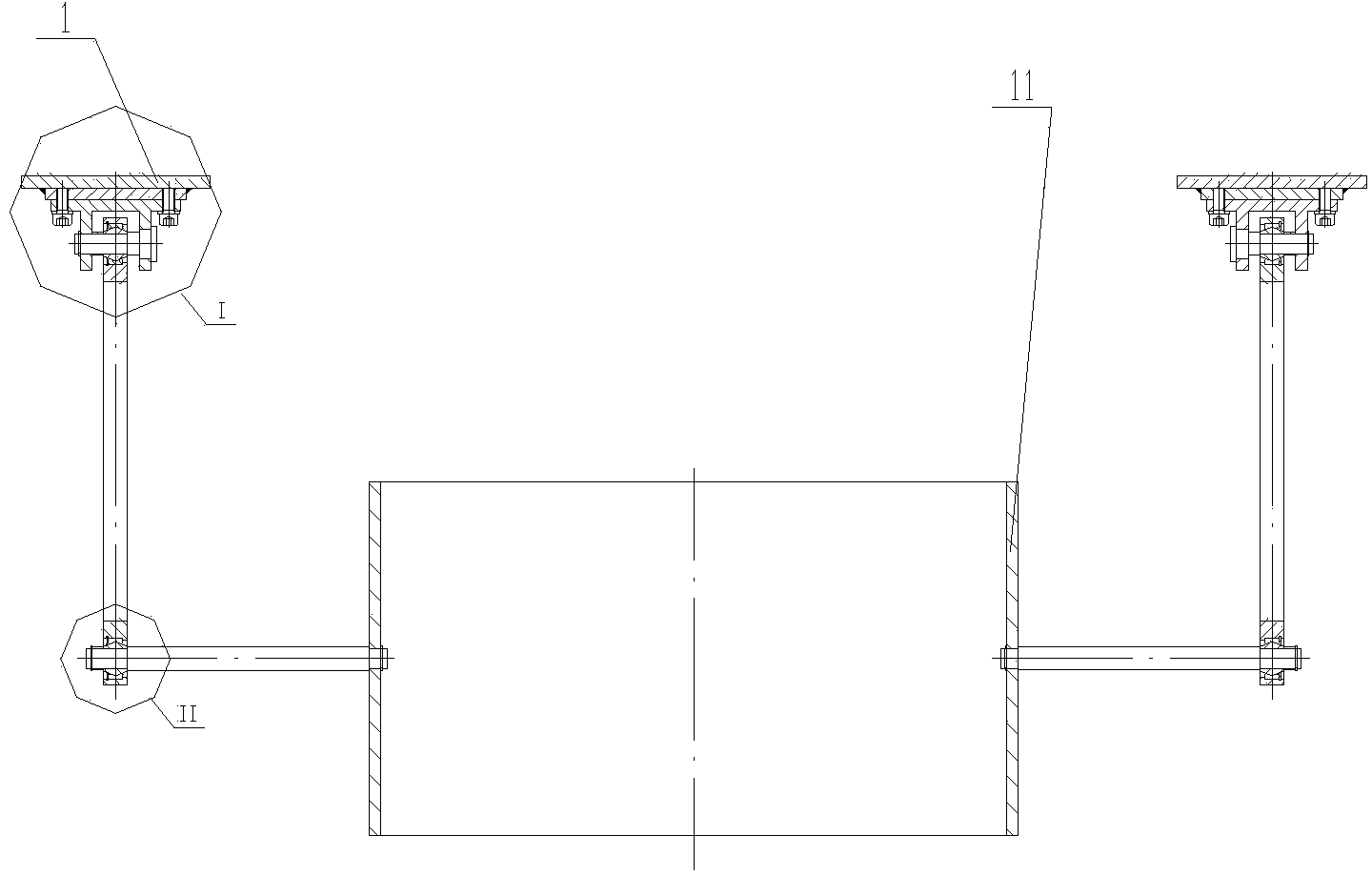

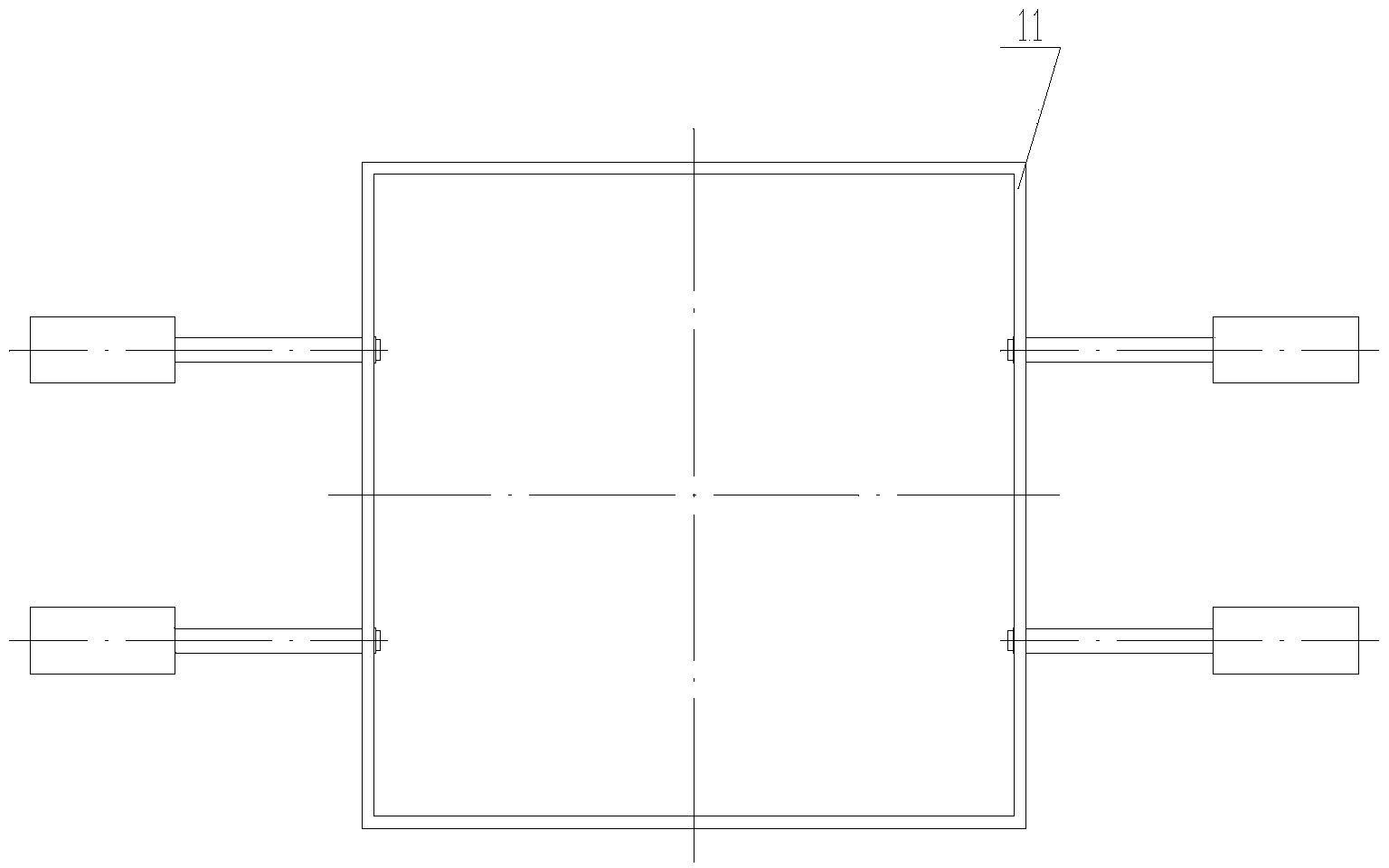

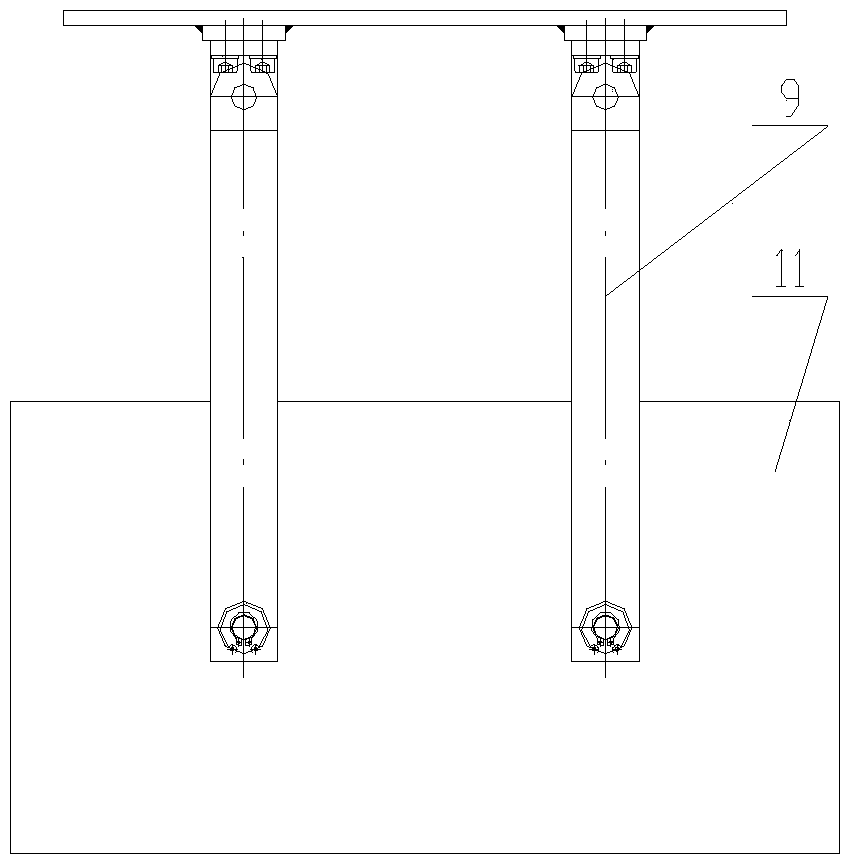

[0064] The present invention as Figure 1-20 As shown, including the universal lifting device and the mud scraper of the drilling tool,

[0065] The universal hoisting device includes a cylinder body 11 and a pair of swing rod assemblies. The swing rod assemblies are respectively connected to the lower part of the drill platform 1, so that the cylinder 11 swings relative to the drill platform;

[0066] The drilling tool mud scraper is arranged in the cylinder body 11, and the drilling tool mud scraper includes an upper mud scraping group and a lower mud scraping group, and the upper mud scraping group is located above the lower mud scraping group;

[0067] The upper mud scraping group and the lower mud scraping group respectively include a pair of mud scraping assemblies 12 arranged oppositely,

[0068] The mud scraping assembly 12 includes an inflatable mud scraping flap 121, a steel ring 122, a swing cylinder 123, a rotating shaft 124, a fixed seat 125, a swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com